Lance holder with multiple tolerance chuck head

A jet tube and chuck technology, which is applied in the field of jet tube brackets, can solve problems such as industrial accidents and insufficient protection of liquid steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

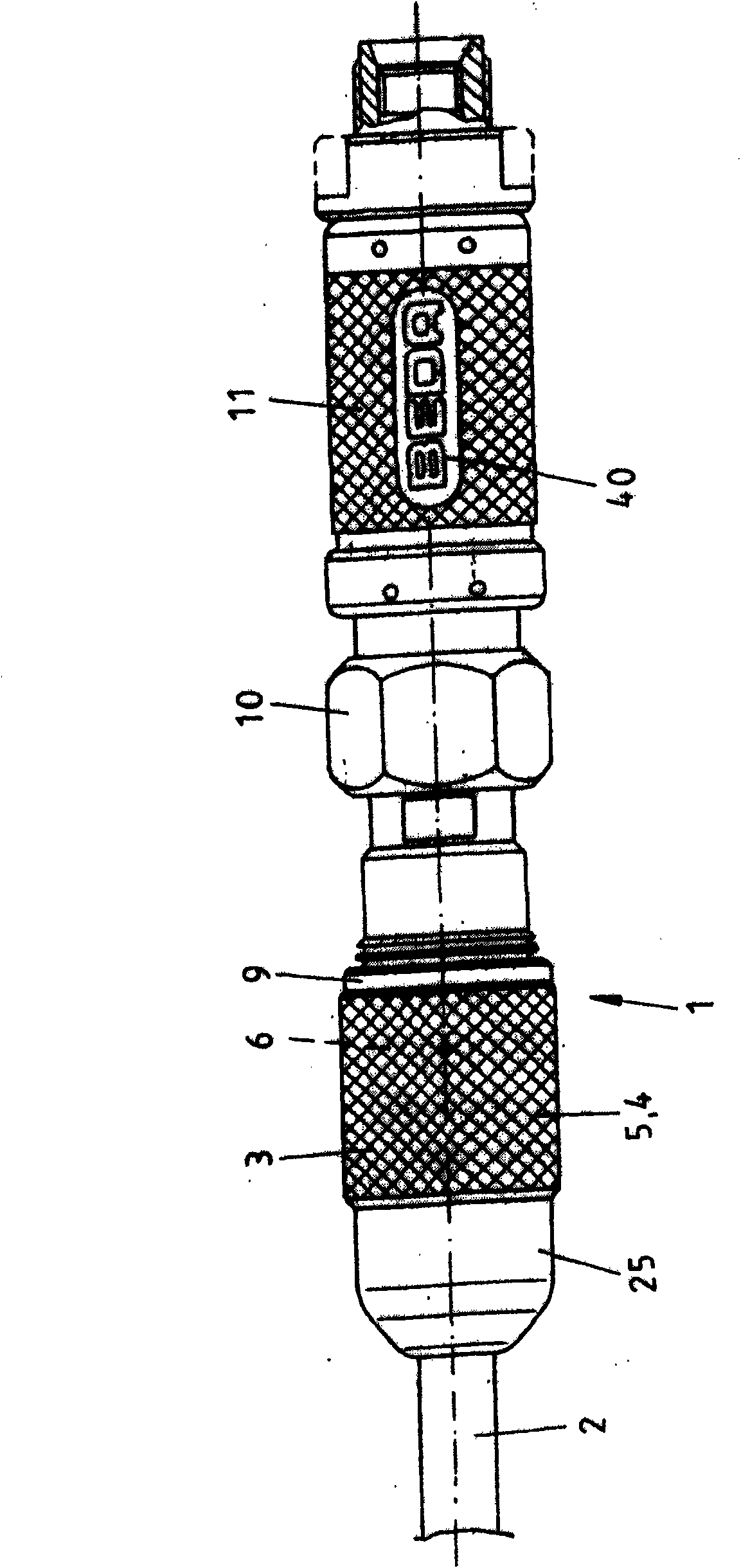

[0024] figure 1 It is a side view of the jet pipe holder 1. The jet tube 2 is inserted into the clamping sleeve 25 from the front. The clamping sleeve 25 or the collet 3 includes a fixing part 4 and a clamping part 5 not shown here. The fixing part 4 cooperates with the clamping part 5 and the sealing sleeve 6, and they are arranged together in the chuck 3 formed as a protective housing 9. Install necessary valves in the next fuse housing 10, which will be discussed in depth later. Tighten the rotary valve 11 on the safety housing 10, and the rotary valve bears the manufacturer's information 40.

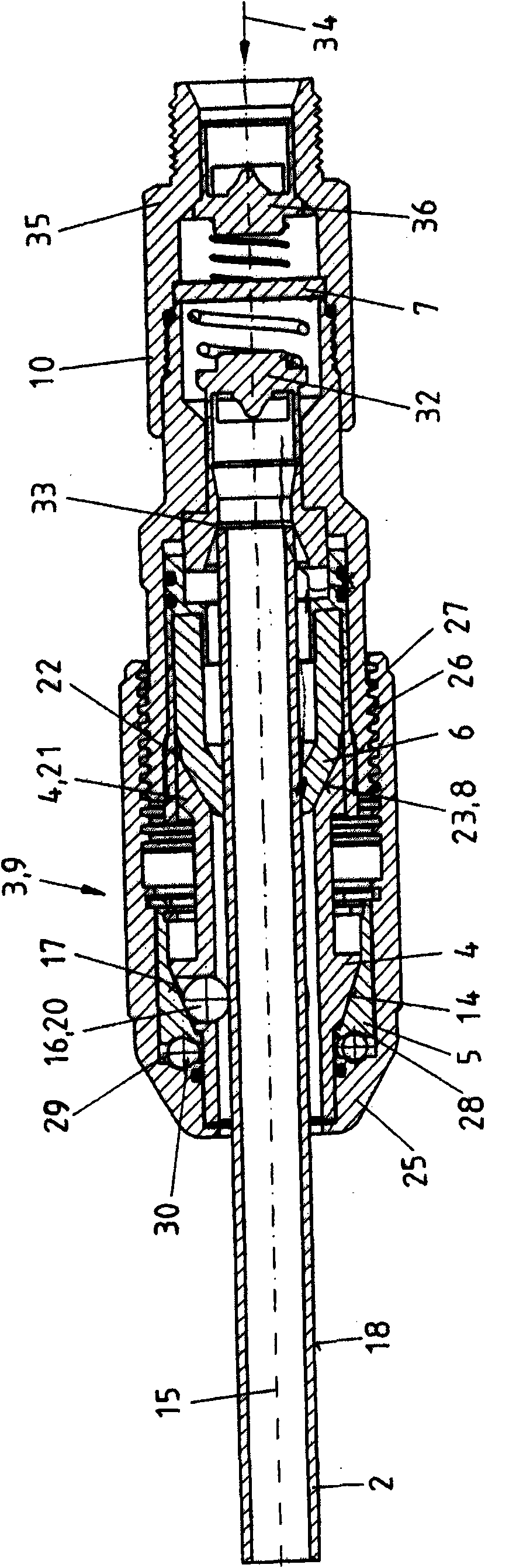

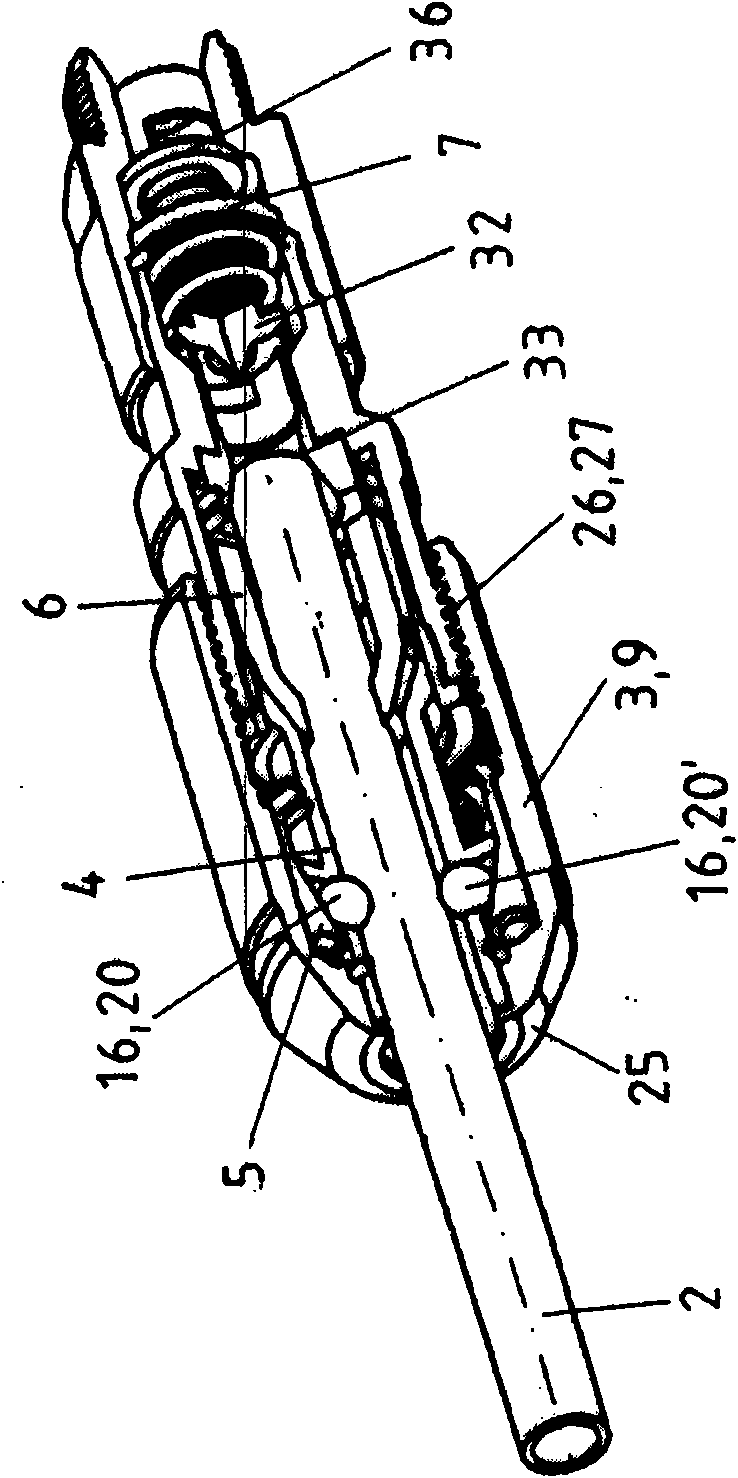

[0025] figure 1 The jet pipe holder 1 shown in figure 2 The middle is represented by the section. It can be seen here that the jet tube 2 is inserted deeply into the jet tube holder 1 through the chuck 3. The above-mentioned sealing sleeve 6 is pressed tightly on the wall 18 of the jet pipe 2 with the wedge-shaped connecting portion 22, so as to perform a complete seal. This wedge-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com