Device to protect edges from separators on a ring spinning machine and ring spinning machine

A technology of ring spinning machine and yarn spacer, which is applied in the direction of spinning machine, continuous winding spinning machine, textile and paper making, etc. It can solve the problem of difficult reinforcement connection, deflection clamp cannot be installed with yarn spacer, etc. problem, to achieve reliable cutting and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

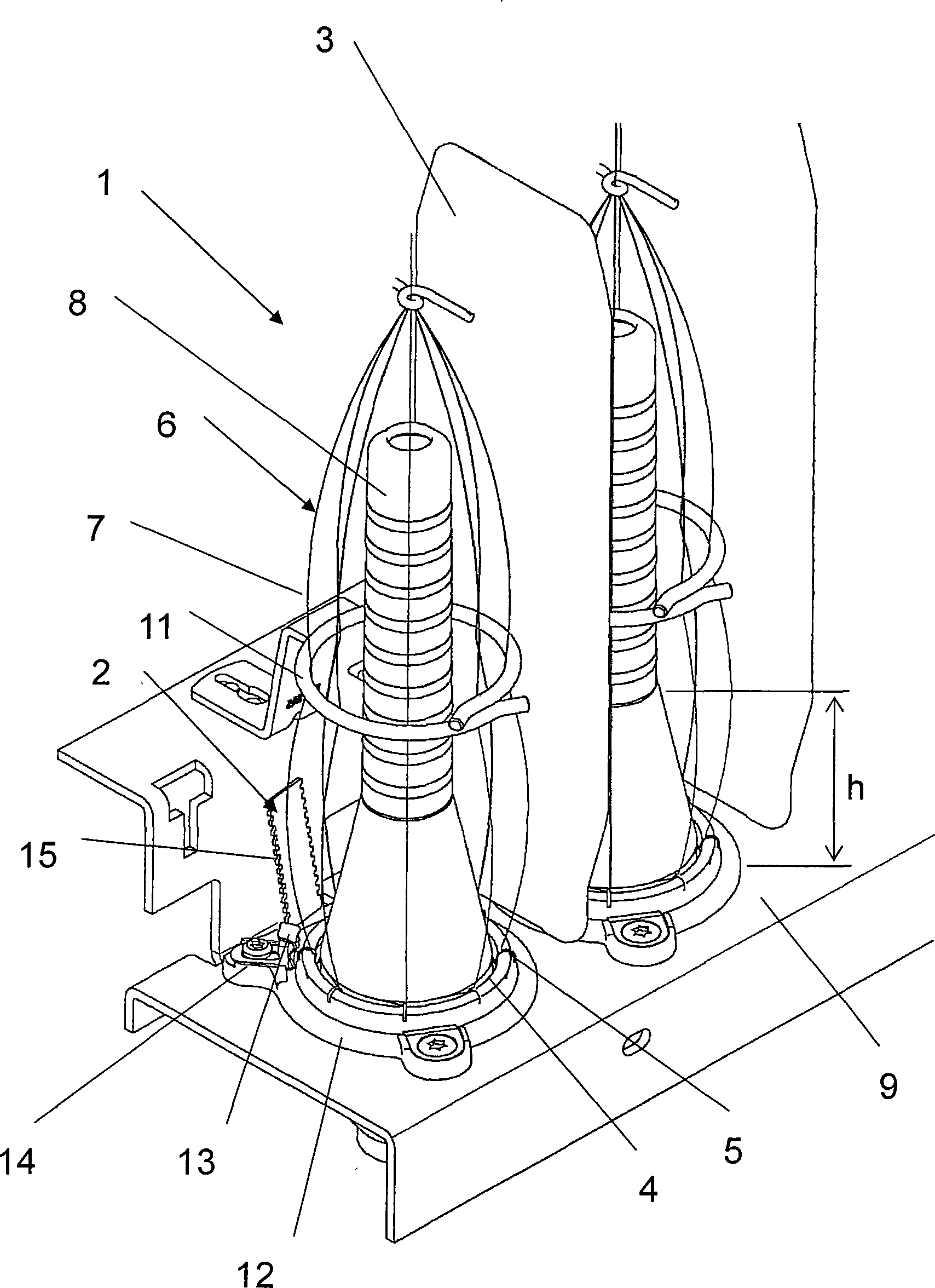

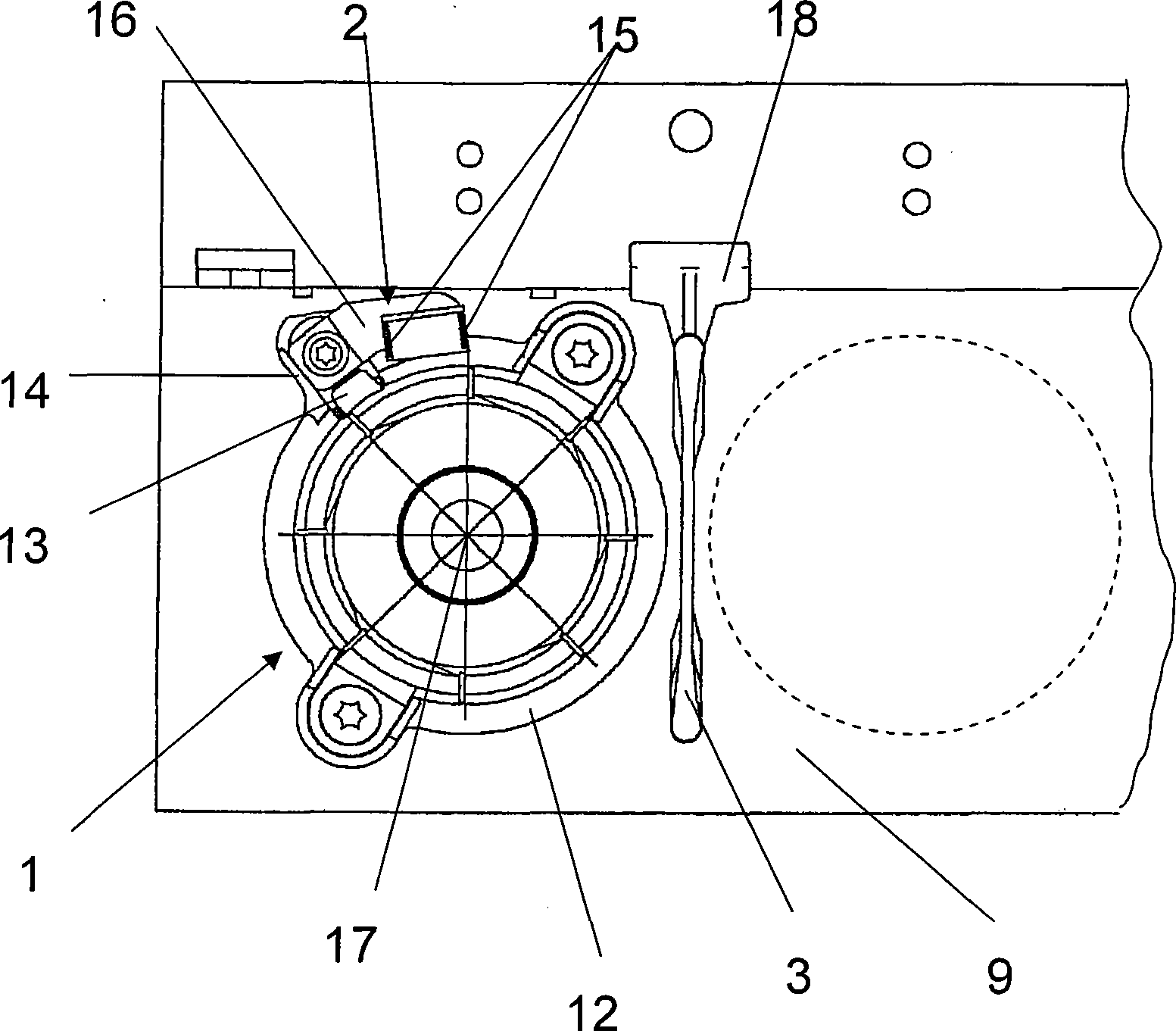

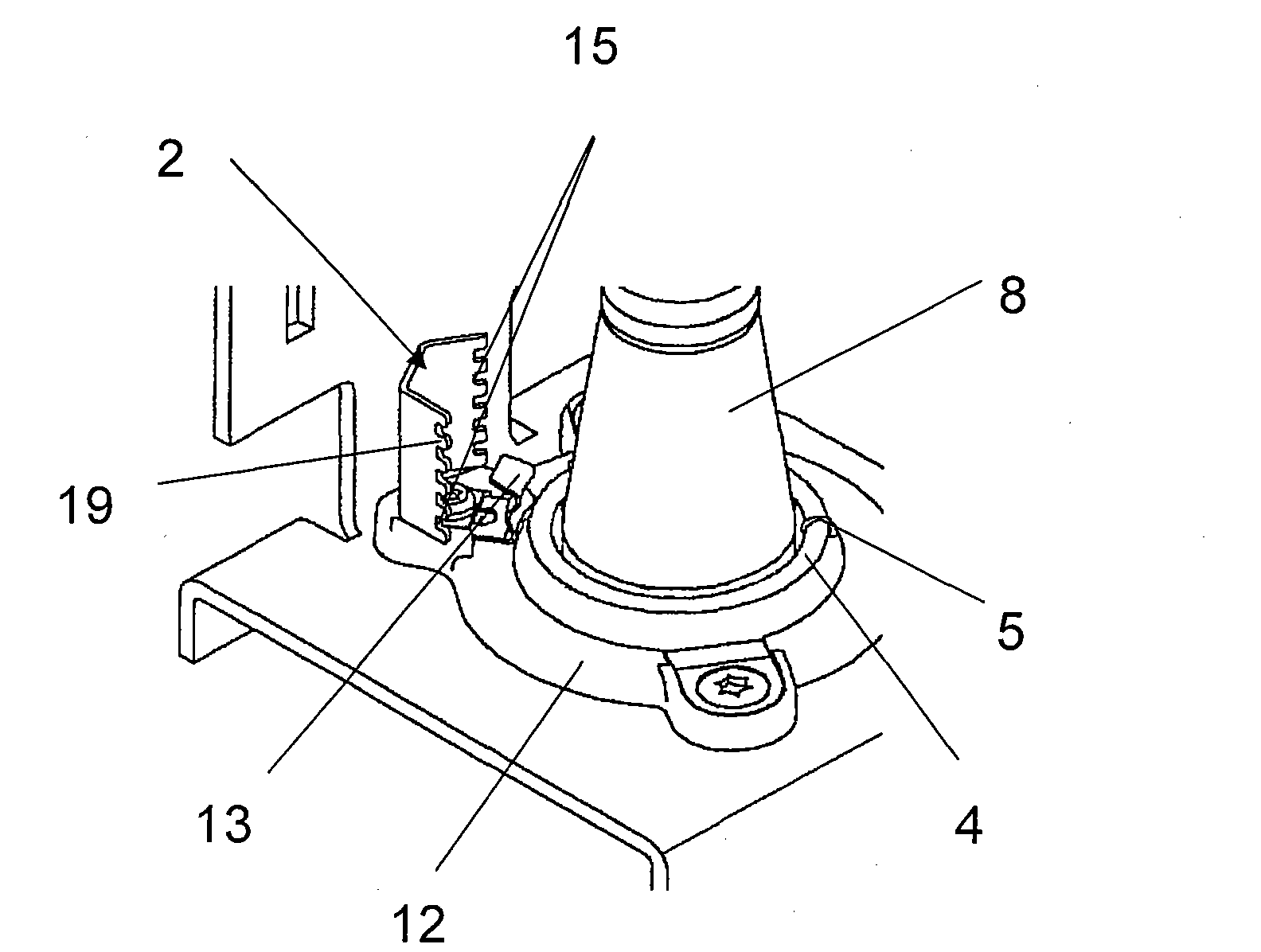

[0030] figure 1 The spinning table 1 of the ring spinning machine is shown in perspective. The ring spinning machine has a plurality of spinning tables 1 arranged adjacent to one another, each of which comprises a ring 4 and a traveler 5 arranged on the ring. Yarn 7 is fed in a known manner to a traveler 5 forming a yarn balloon 6 from which the yarn is wound onto a bobbin 8 placed on a rotating spindle to form a bobbin yarn. The ring 4 of the spinning stand 1 is fixed to a continuous ring bar 9 . In order to wind up the yarn, the ring bar 9 can be moved up and down by the stroke h of the ring bar in a known manner. Furthermore, a balloon constrictor ring 11 is provided on the spinning table 1 .

[0031]Yarn spacers 3 are arranged between the spinning tables 1 respectively, and in this embodiment, the yarn spacers 3 are designed as disk yarn spacers. This yarn spacer 3 prevents the yarn balloons 6 of adjacent spinning stations 1 from coming into contact with each other an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com