Terry-shearing method in towel-weaving process and terry-shearing device thereof

A technology for cutting piles and towels, which is applied in textiles, papermaking, knitting, cutting piles, etc. It can solve problems such as inability to cut, troublesome machine maintenance and maintenance, and difficulty in cutting, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Now illustrate the present invention in conjunction with accompanying drawing and embodiment.

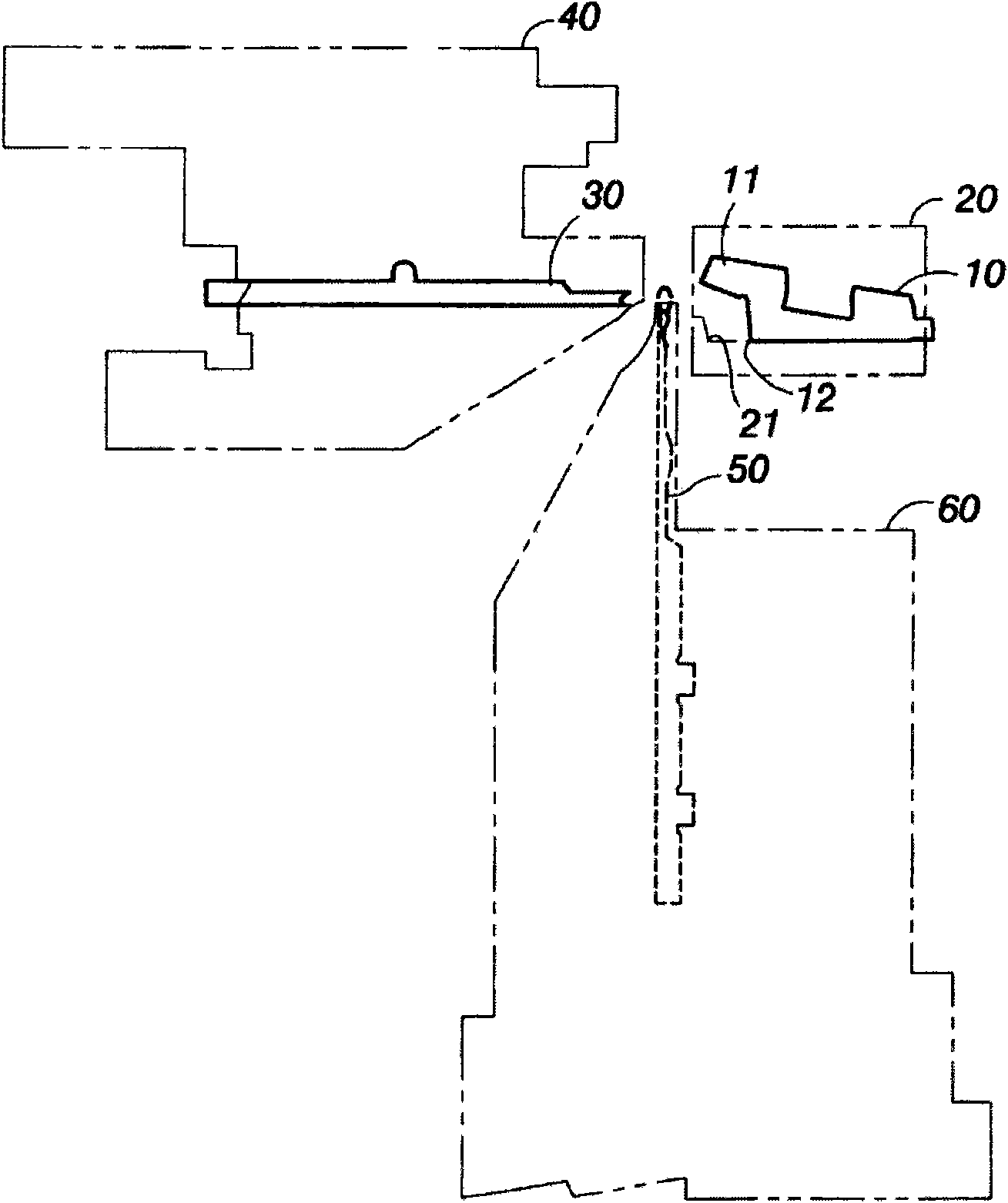

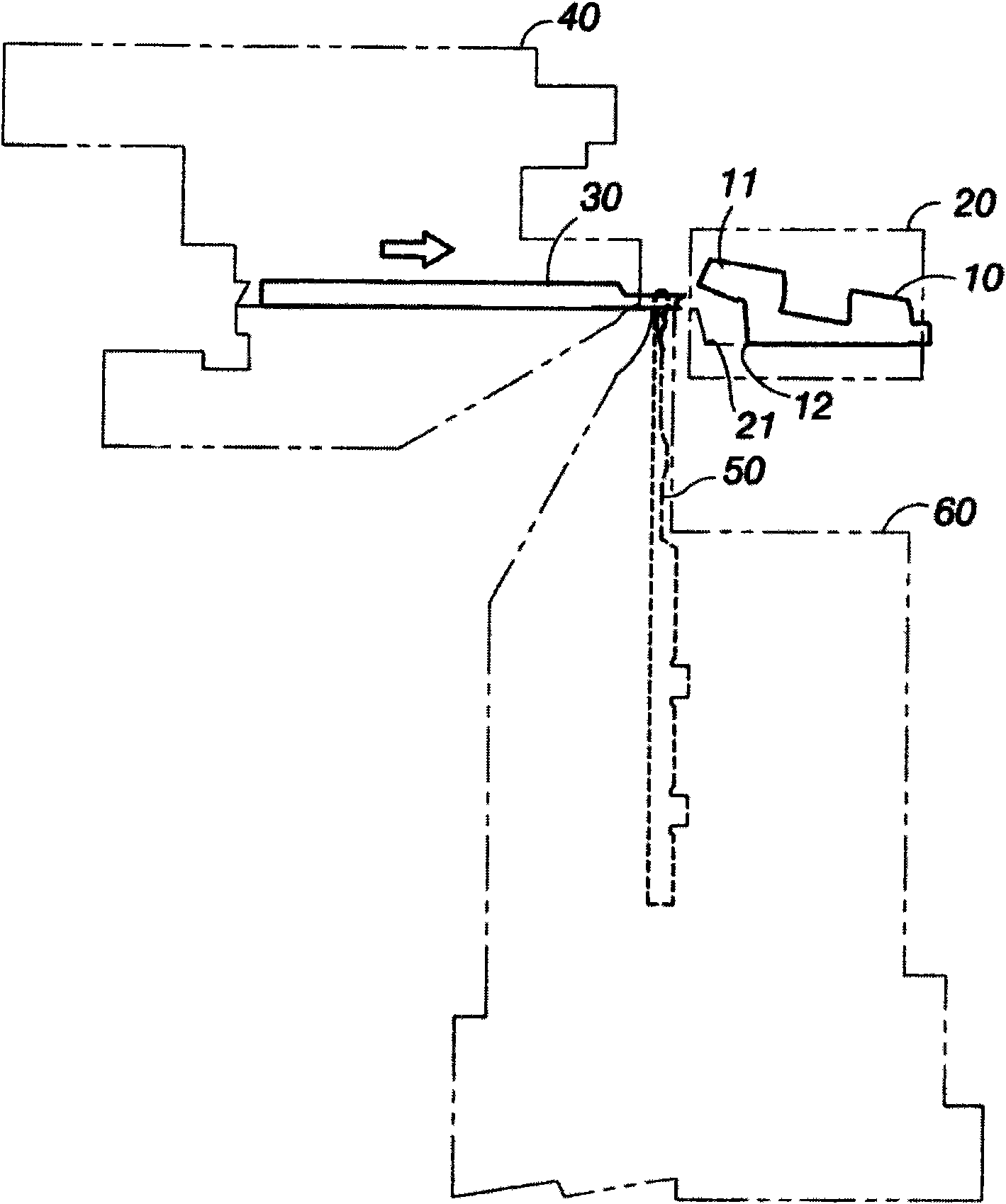

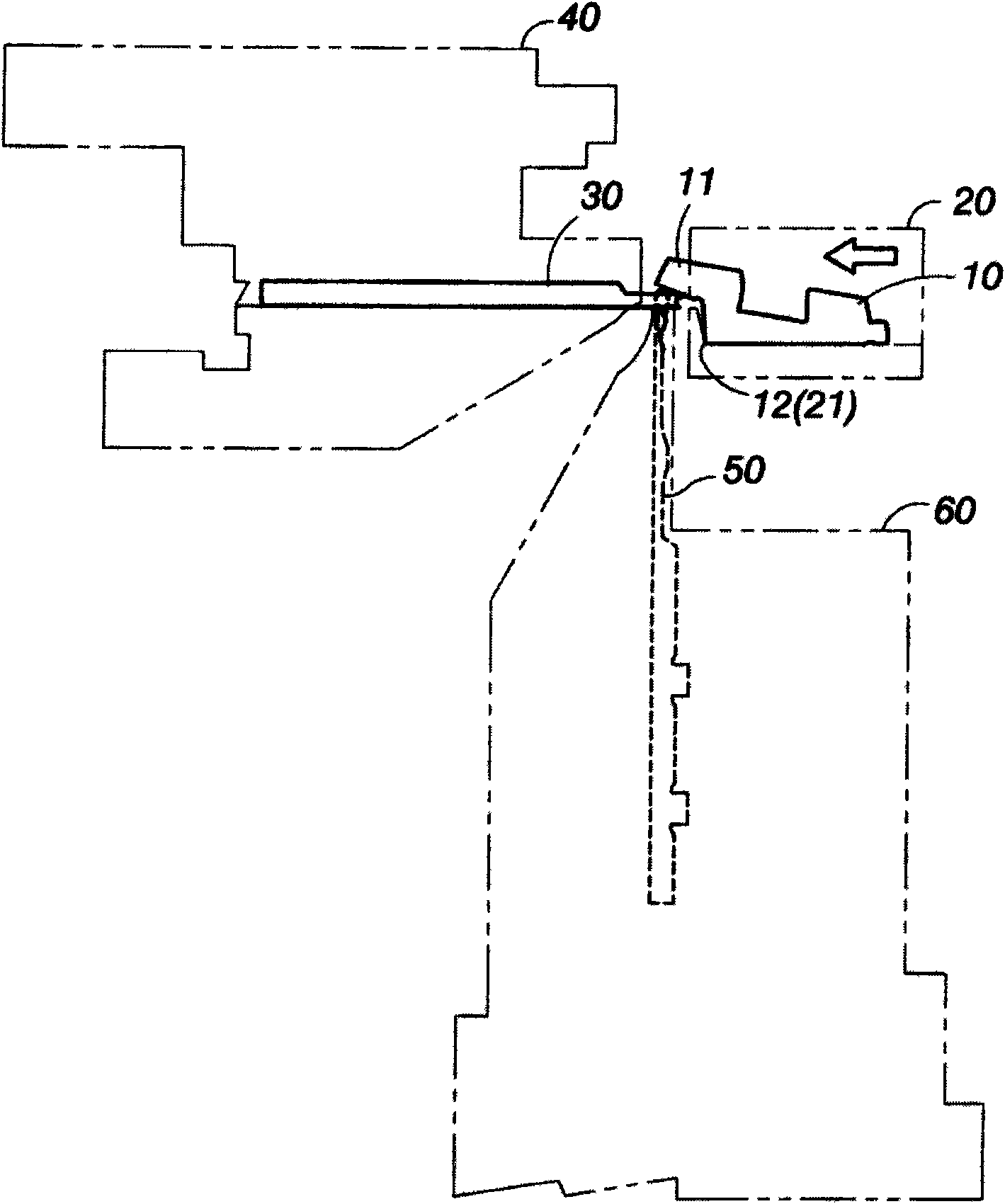

[0018] like figure 1 The loop cutting device of the terry knitting machine shown is mainly composed of a gram sheet 10 , a gram ring 20 , a sliding sheet 30 and a sliding seat 40 . The green sheet 10 and the green ring 20, the sliding sheet 30 and the sliding seat 40 are respectively arranged at the left and right needle outlet ends of the knitting needle 50 of the towel knitting machine, and the knitting needle 50 is erected on the needle cylinder 60 to perform vertical reciprocating motion , and cooperate with the green sheet 10 that moves back and forth laterally to make the yarn loop.

[0019] One of the main functions of the raw gram sheet 10 is to cooperate with the knitting needle 50 of the towel knitting machine, so that the yarn is looped at the needle exit end of the knitting needle 50; another main function of the raw gram sheet 10 is to cooperate with The slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com