Hand-operated threshing machine

A hand-cranked and cranked technology, applied in agricultural machinery and implements, threshing equipment, applications, etc., can solve the problems of high labor intensity and low efficiency, and achieve the effect of solving the field problem, high efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

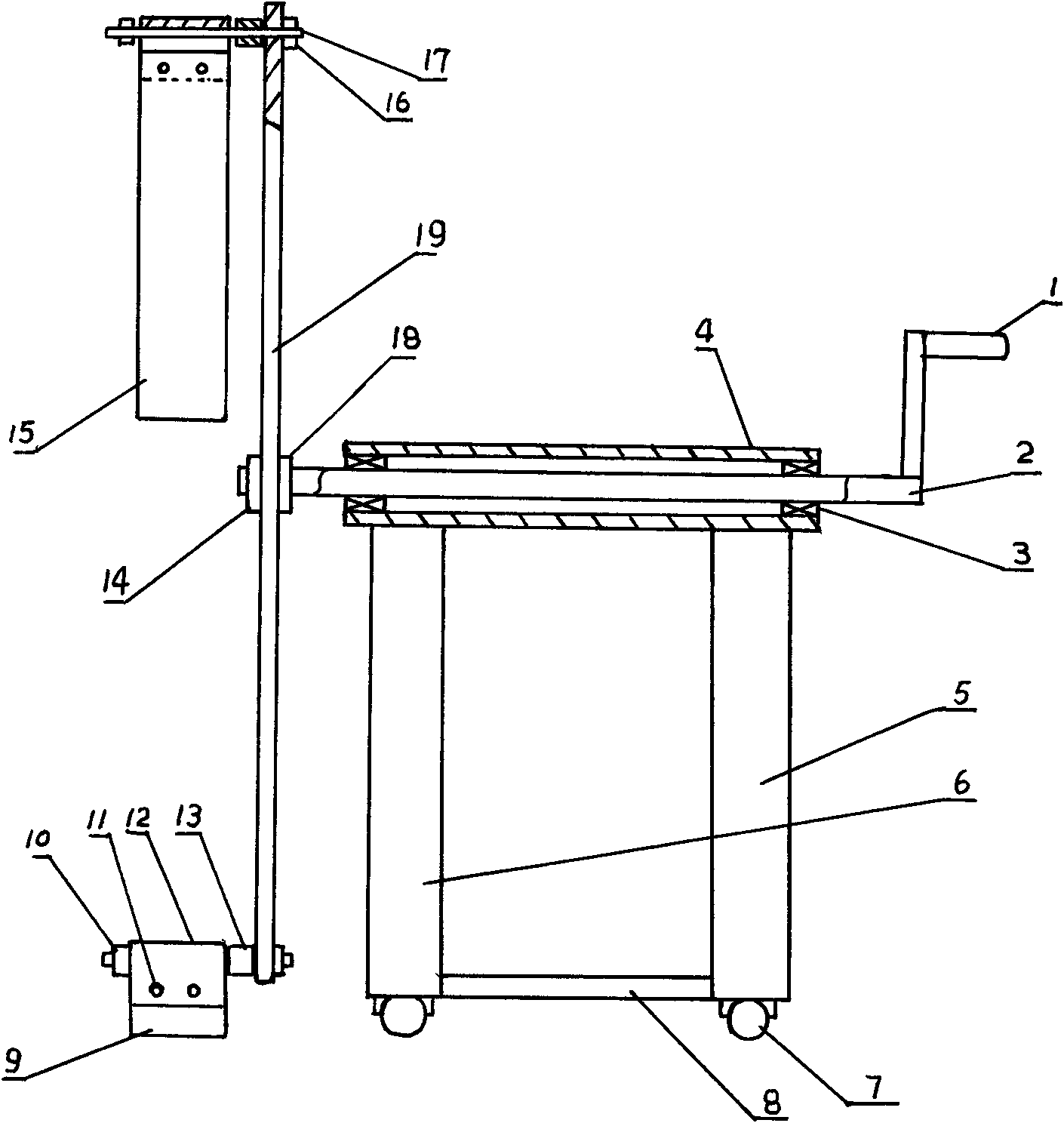

[0008] There is a field bar 19 and two field boards 9,15 for playing. Two playing field boards 9,15 are contained in the two ends of playing field bar 19 by fixed plate 12 and bearing pin 17 respectively. Playing field board 9,15 is contained on the fixed piece 12 by screw 11, and fixed piece 12 is sleeved on pin shaft 17. Spacer sleeve 13 is also housed between fixed piece 12 and playing field bar 19, and bearing pin 17 two ends adopt fixed nut 10,16 to fix.

[0009] The main shaft 2 is contained in the sleeve pipe 4 through the bearing 3, and the sleeve pipe 4 is fixed above the front bracket 6 and the rear bracket 5. The field bar 19 is fixed on the front end of the main shaft 2, and fixed nuts 14, 18 are installed before and after the field bar 19.

[0010] The length of playing field board 9,15 is 50-80cm; The length of playing field bar 19 is 170-200cm. The height of front and back support 6,5 is identical, is 90-110cm. In order to be easy to crank without feeling to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com