Novel cabinet and manufacturing method thereof

A manufacturing method and a new type of technology, applied in the direction of chemical instruments and methods, furniture parts, household appliances, etc., to achieve the effect of weight reduction, thickness reduction, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

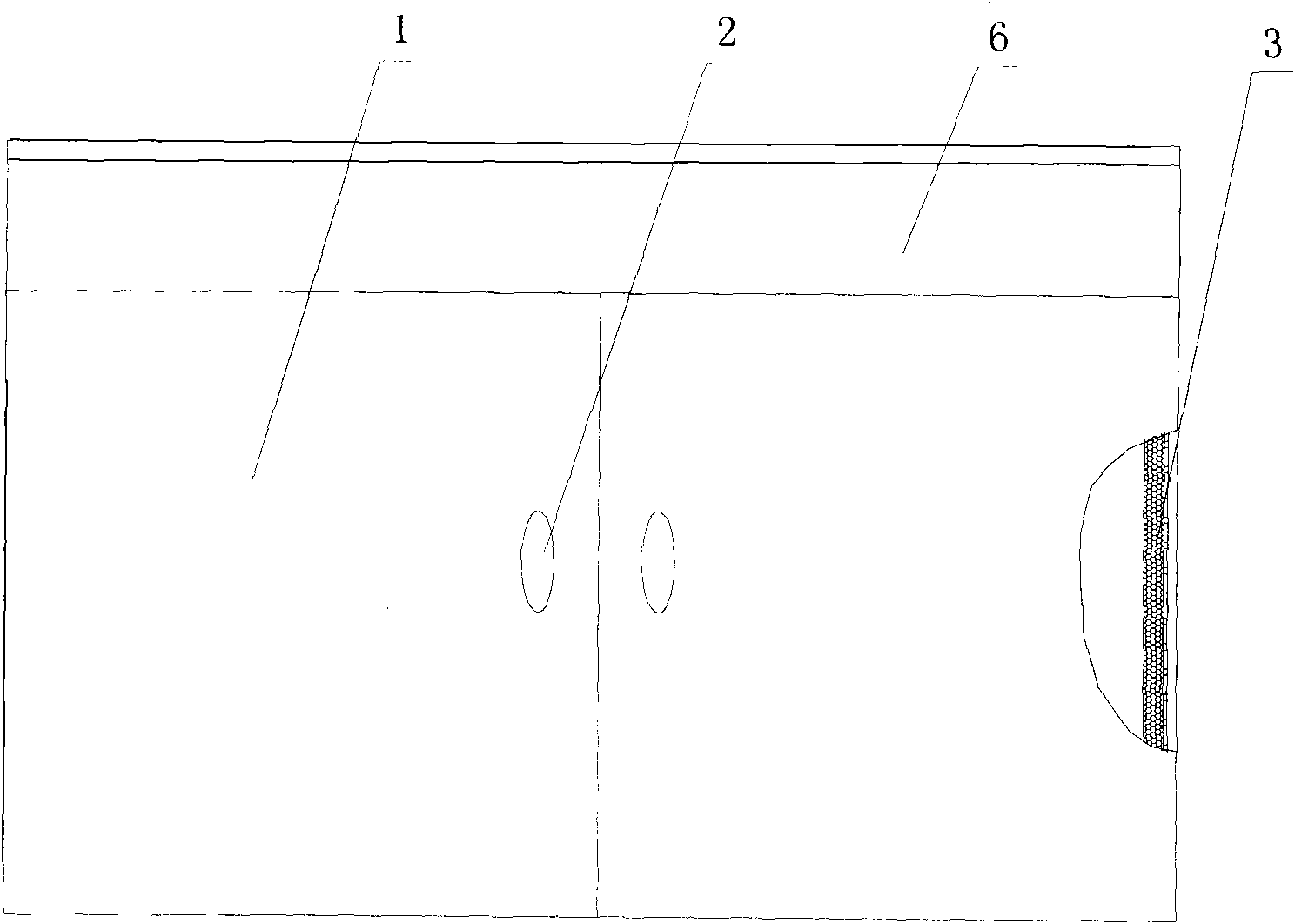

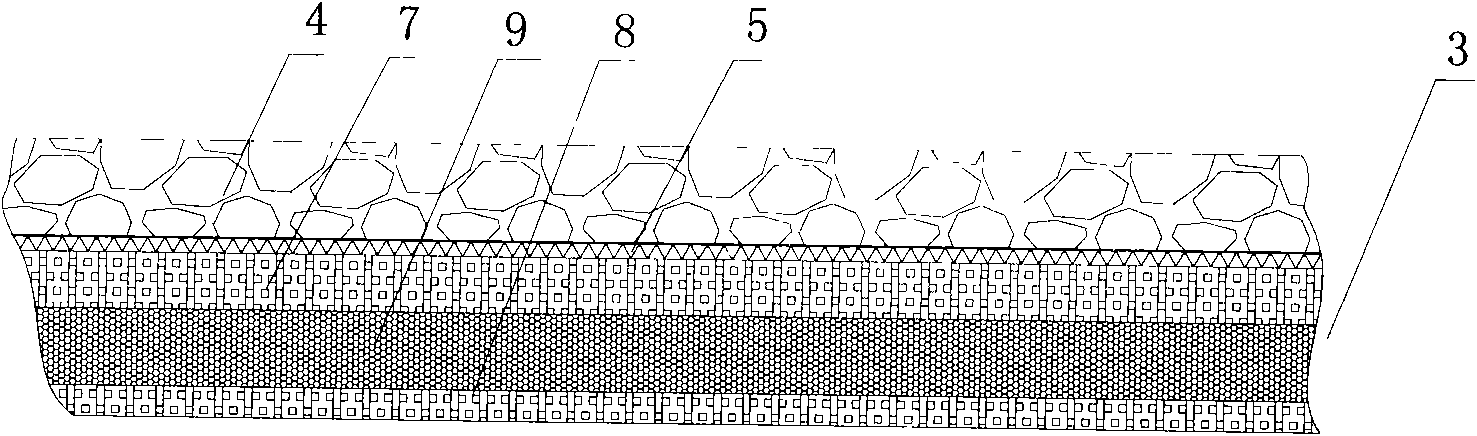

[0011] Such as figure 1 , figure 2 As shown, the novel cabinet of the present invention adopts composite manufacturing of honeycomb material and marble slab. Cabinet door (1), cabinet body (6) all use this composite plate. Handle (2) then available other materials. Honeycomb material (3) and marble (4) are bonded together by adhesive glue (5). Wherein the honeycomb material (3) can be formed by wrapping the front and back of the inorganic material with light weight and good toughness materials such as honeycomb aluminum or honeycomb plastic. And these materials have good waterproof performance. Its manufacturing method is: making aluminum or plastic and other light-weight and tough materials into a honeycomb shape, further reducing its weight and improving its rigidity, and then wrapping it front and back with inorganic materials. Stone materials such as marble are cut into thin plates, such as thin plates that can be cut into 3-5mm, and then the stone thin plates and ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com