A coal mine gas drainage pipeline water discharge device

A technology for coal mine gas and gas drainage, which is applied in the field of water drainage devices for coal mine gas drainage pipelines. burden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

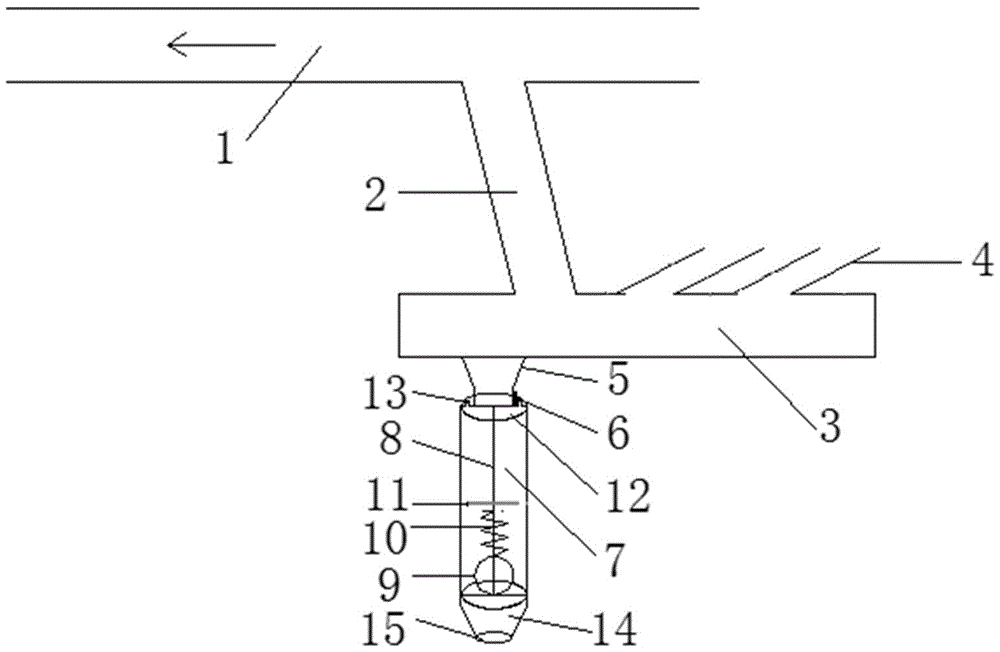

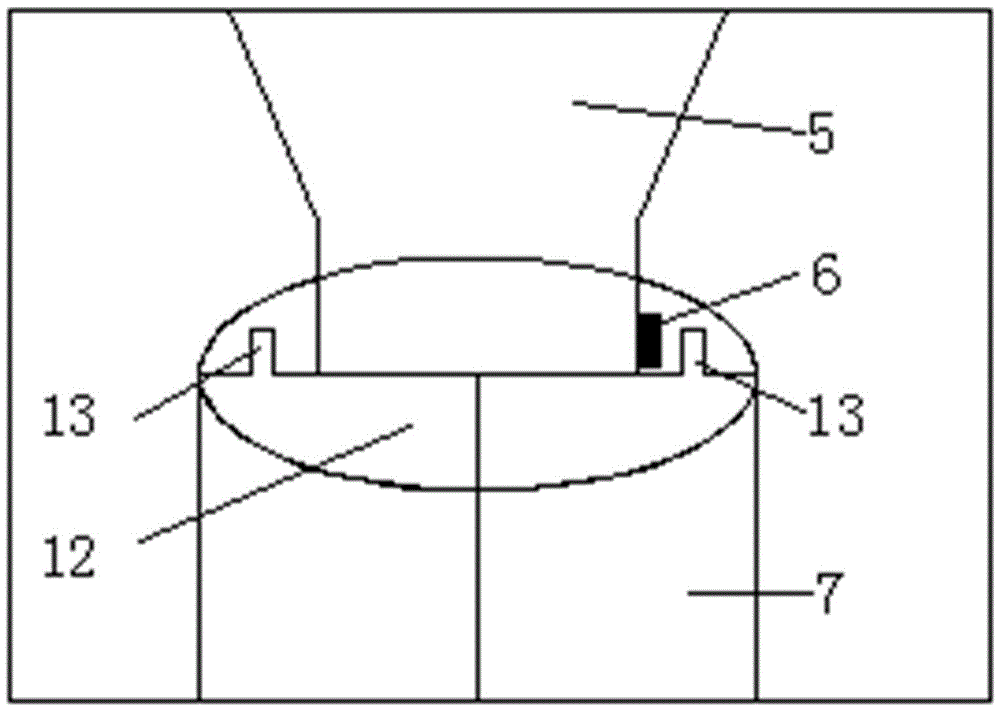

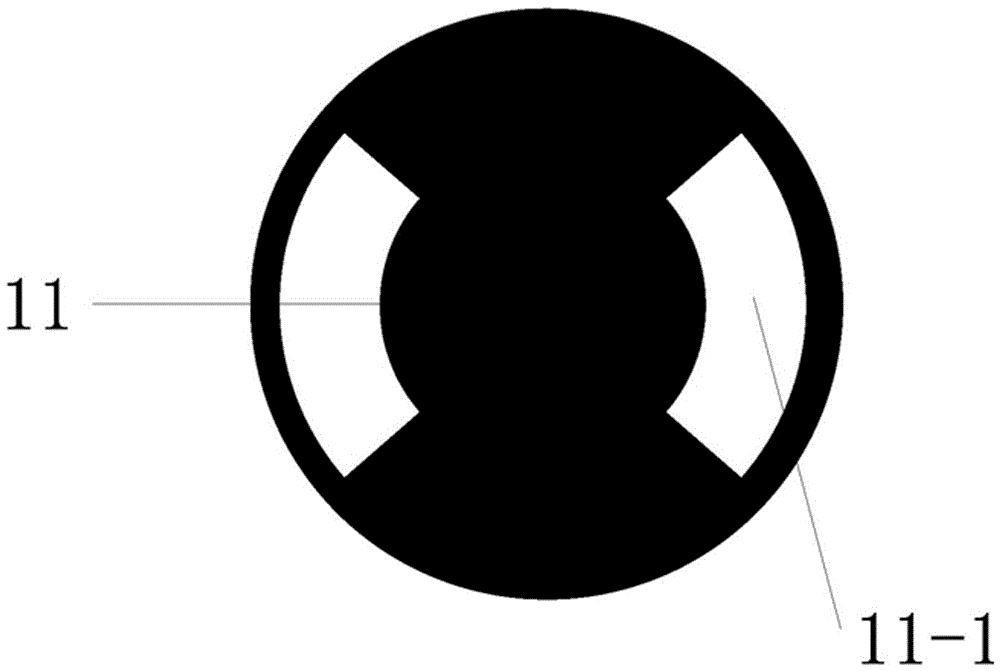

[0014] Such as figure 1 As shown, a coal mine gas drainage pipeline water discharge device includes three major components: a water inlet device, a water storage device and a water discharge device; Funnel 5, the water discharge device includes a water storage pipe 7, a water discharge funnel 14, and the water inlet funnel 5 is installed in the low-lying place of the gas drainage collection pipeline 3, and the gas drainage collection pipeline 3 is installed obliquely at a small angle to facilitate the flow out of the borehole The water is collected into the water inlet funnel 5 in the low-lying place by gravity, the gas drainage collection pipeline 3 is connected with the transparent water inlet funnel 5, and the water inlet valve 6 is arranged at the water outlet of the water inlet funnel 5, by closing or opening the valve 6 is used to control the dust removal and cleaning of the water discharge device or when it is restored to use; the other end of the transparent water inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com