Technical method for multilayer glue dispensing in production process of EMI product

A technology of production process and process method, applied in the direction of coatings, devices for coating liquid on the surface, electrical components, etc., can solve the problems of low production efficiency and high production cost, and achieve improved production efficiency, reduced labor costs, and reduced production The effect of links and people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

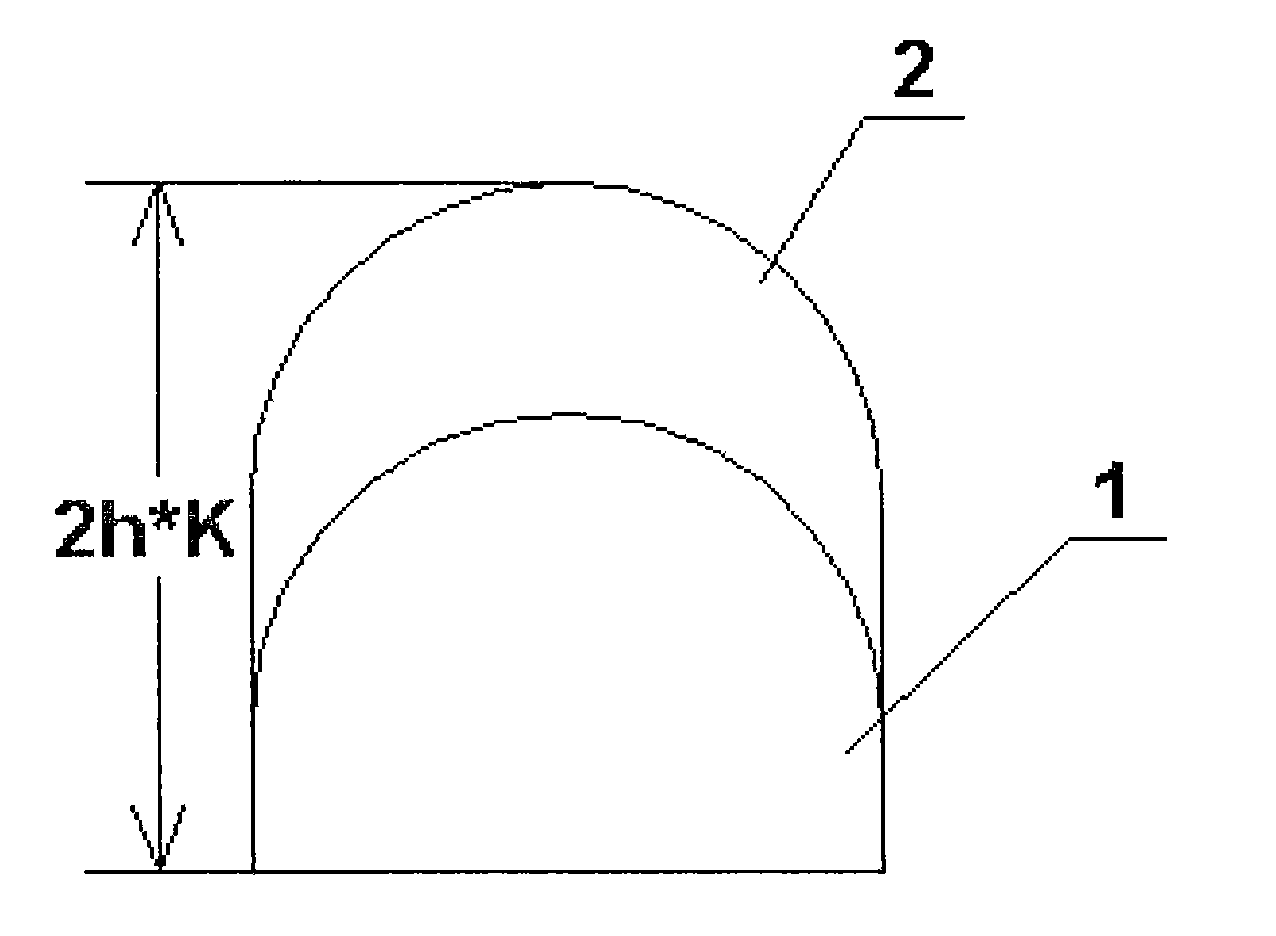

[0019] Embodiment: a kind of process method of multi-layer dispensing in EMI product production process (see figure 2 ), characterized in that it comprises the following steps:

[0020] (1) Place the substrate to be dispensed on the jig prepared in advance;

[0021] (2) Use the viscosity of the conductive adhesive itself to directly realize the bonding and fusion of the adhesive strip and the adhesive strip,

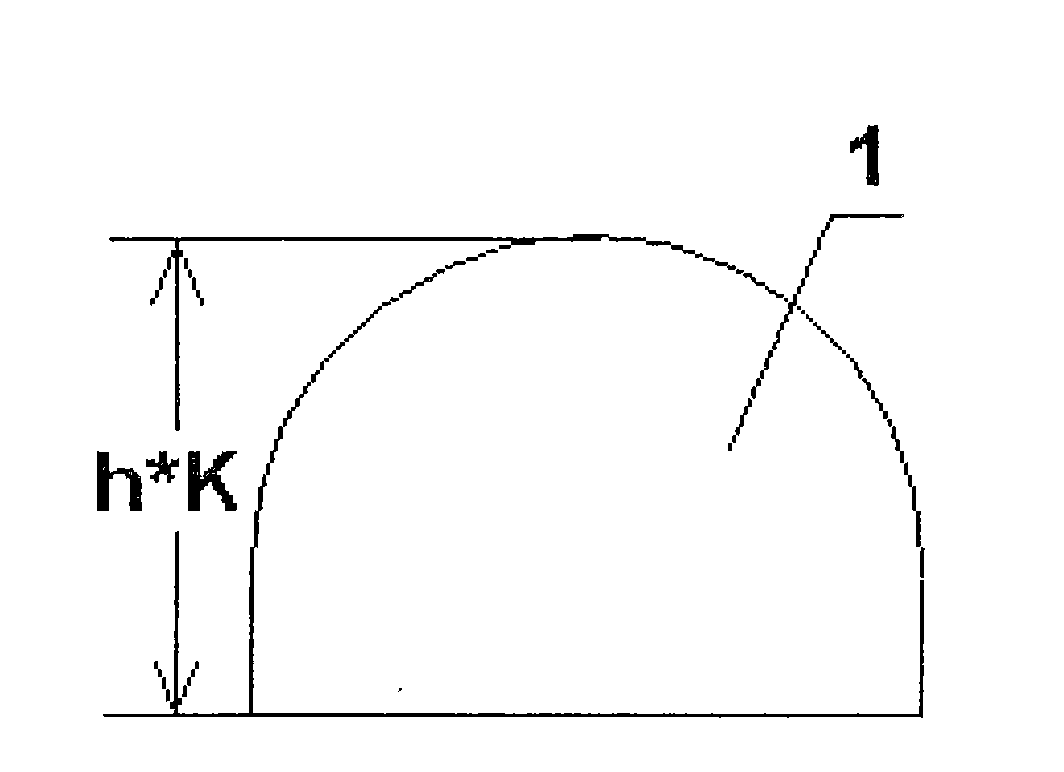

[0022] Adjust the dispensing program so that the dispensing machine runs more than two times in one program, including two times; there should be differences in the initial height during the two runs, and the total height of the glue strip structure of the dispensing layer is 2h*K; where h is the layer height of the single-layer rubber strip; K is the correction coefficient of the dispensing layer height determined by the thixotropy of the conductive adhesive, K=R h / w *k`; when n=2, 0.9 n-1 Then k`=0.9;

[0023] (3) Complete the first layer of dispensing of the prod...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap