Clamp-replacing device

A fixture replacement and fixture technology, applied in the direction of chucks, manufacturing tools, manipulators, etc., can solve the problems of reducing production efficiency, production pause, restricting automatic production, etc., and achieve the effect of rapid replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings.

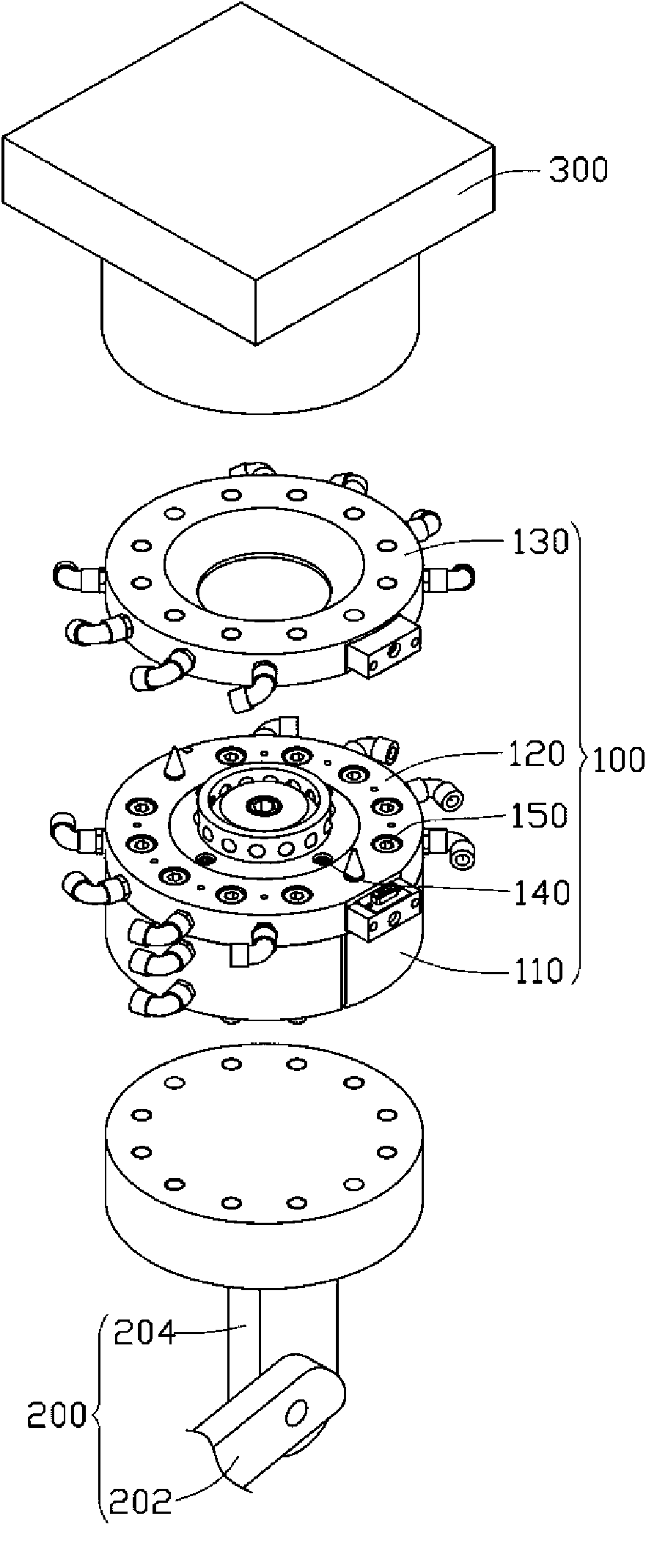

[0014] Please also refer to figure 1 and figure 2 , the fixture replacement device 100 provided by the present invention is used to replace the fixture 300 for the mechanical arm 200 . The robotic arm 200 includes a fifth shaft 202 and a sixth shaft 204 connected to the fifth shaft 202 .

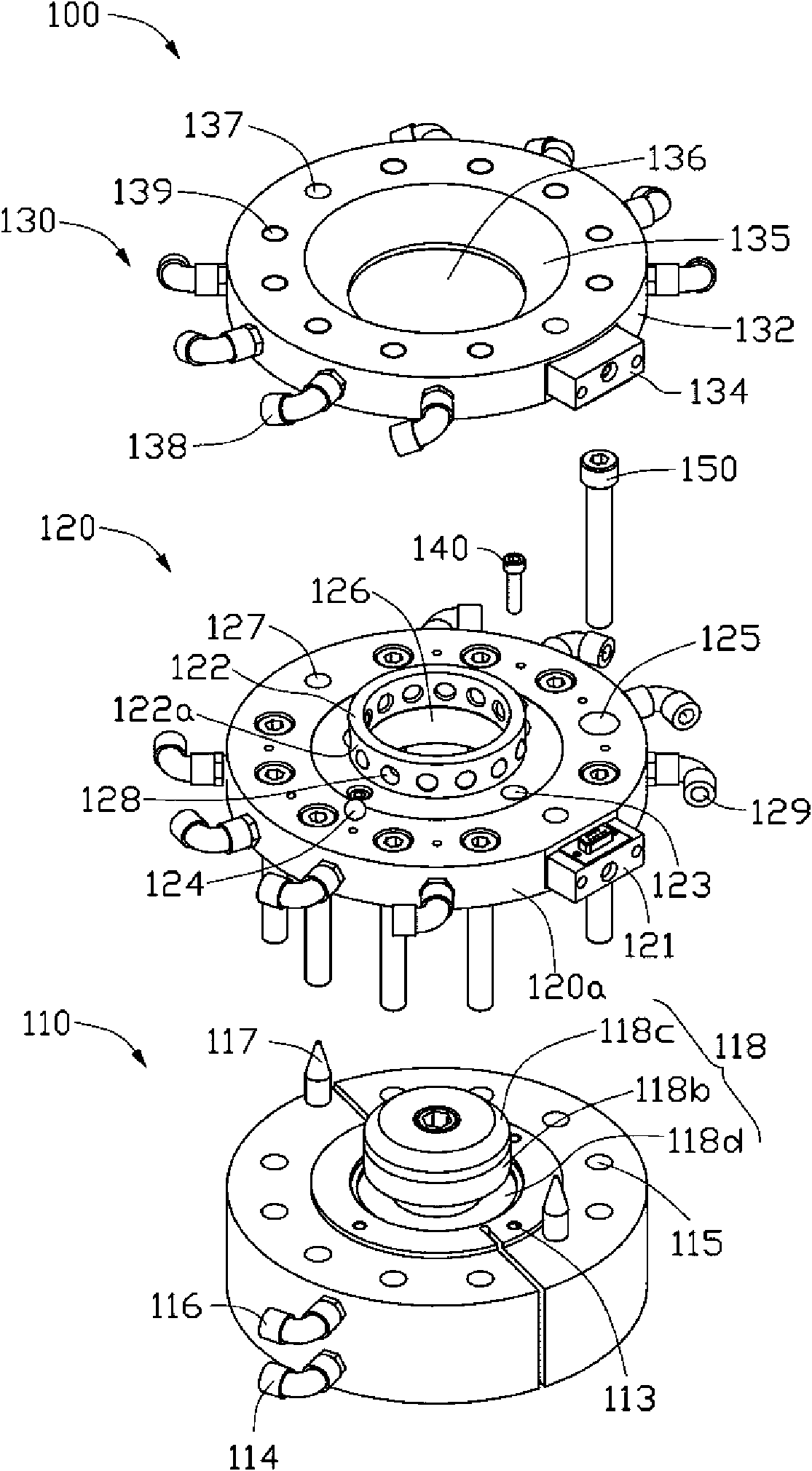

[0015] The fixture replacement device 100 includes a body part 110 connected to the sixth shaft 204 , a replacement part 120 , a coupling part 130 , three first screws 140 , and a plurality of second screws 150 .

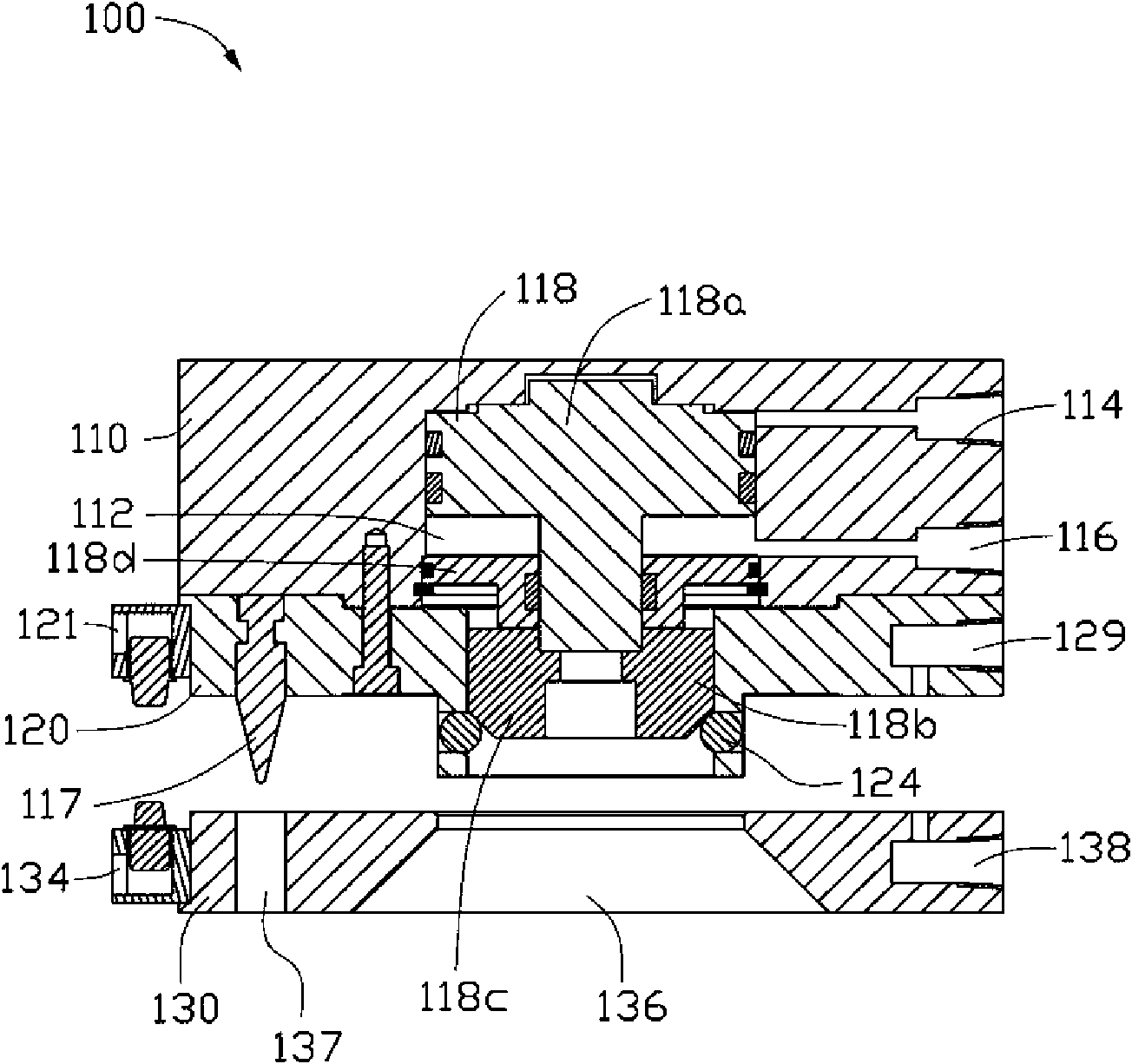

[0016] Please also refer to figure 1 , figure 2 and image 3 , the body portion 110 includes a housing space 112, a first gas passage 114, a second gas passage 116, a piston 118, three first screw holes 113 corresponding to the first screw 140, a plurality of first screw holes 113 corresponding to the first screw 140, The plurality of second screws 150 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com