Two color injection molding die and injection molding method

A two-color injection molding and mold technology, applied in the field of injection molds, can solve the problems of high production cost and many processes of two-color injection molding, and achieve the effect of reducing development investment and processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

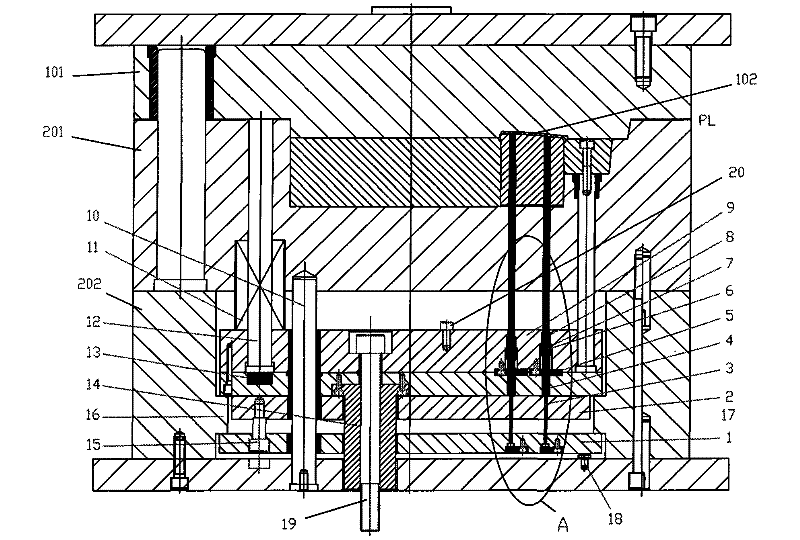

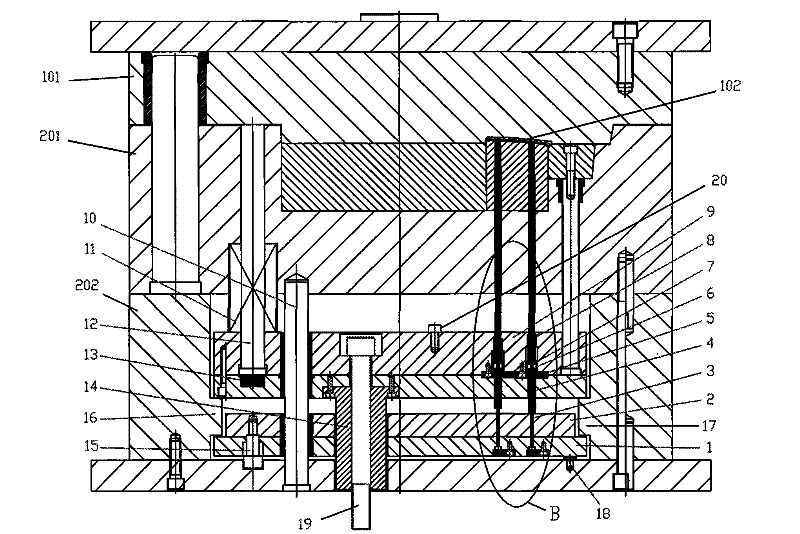

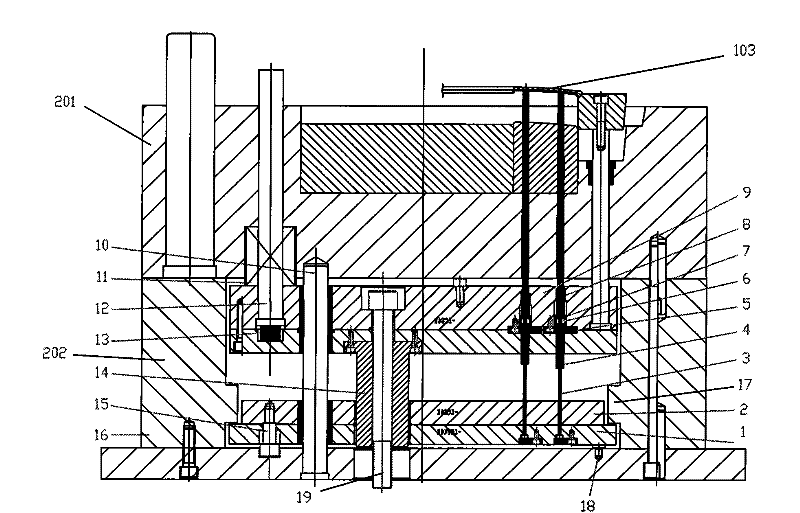

[0021] like figure 1 As shown, the two-color injection mold proposed by the preferred embodiment of the present invention includes a fixed mold 101 and a movable mold composed of a core 201 and a base 202 . Limiting bosses 16, 17 are arranged on both sides of the left and right square irons (horn irons) in the base 202, and the first group of needle plates 1, the second group of needle plates 2 and the third group of needle plates 9 are stacked successively in the base. The third group of needle plates 1, 9 are respectively located below and above the position-limiting bosses 16, 17, and the position-limiting protrusions respectively limit the distances that the needle plates of the first group move upward and the needle plates of the third group move downward. On the left side of the bottom plate of the movable mold, there is vertically provided a central guide column 10 for the three groups of needle plates to slide, and on the left side between the first and second groups o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com