Crude oil gas-liquid separation process integration method and equipment

A process integration and oil-gas-liquid technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of multiple distribution station equipment, complex process flow, large floor area, etc., and achieve technological The effect of simple process, short construction period and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

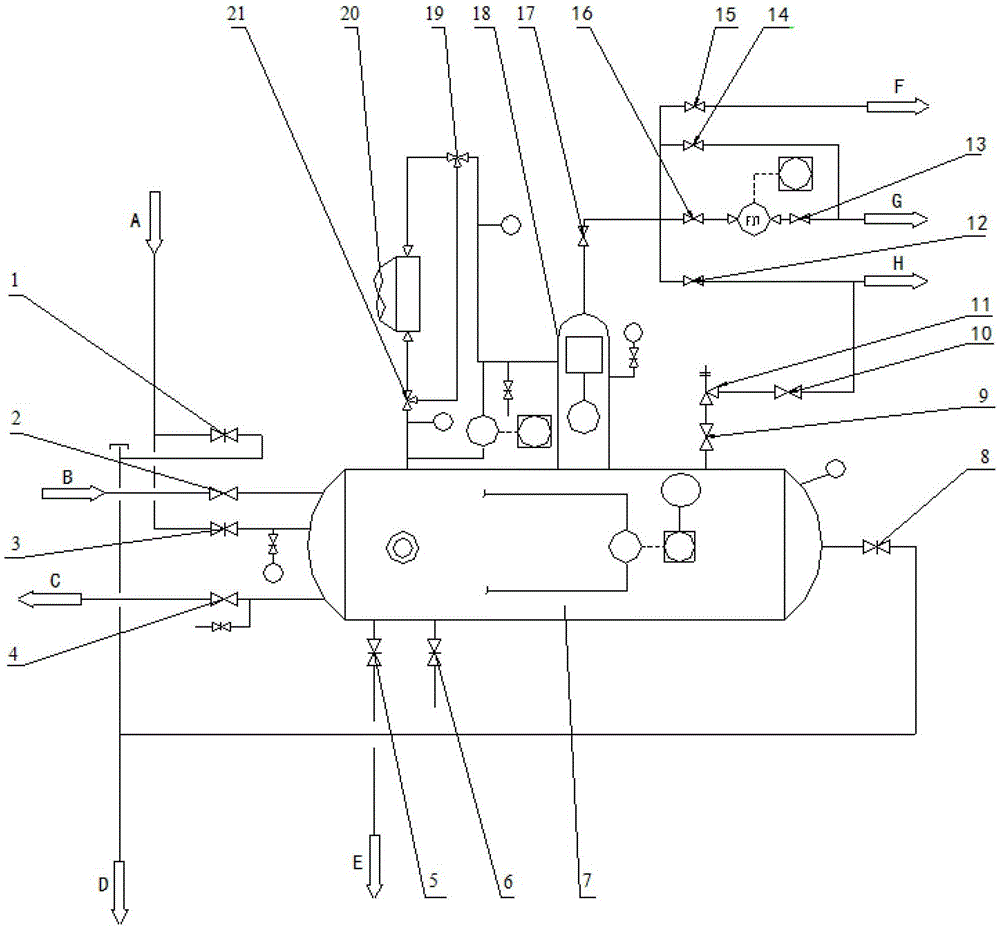

[0024] The connection structure of the crude oil gas-liquid separation process integration equipment of the present invention is as follows:

[0025] The incoming oil pipeline A of the heating furnace is connected to the external delivery pump pipeline D through the bypass pipeline gate valve 1, and at the same time is connected to the closed buffer tank 7 through the well group incoming oil gate valve 3, and the closed buffer tank 7 is connected to the external delivery pump pipeline D through the external delivery gate valve 8.

[0026] The airtight buffer tank 7 is connected to the air cooler 20 through the three-way valve I21, the air cooler 20 is connected to the associated gas separator 18 through the three-way valve II19, and the three-way valve I21 is connected to the three-way valve II19 which can be used as a bypass process. After the associated gas liquid separator 18 is connected to the stop valve 17 of the liquid separator, one path is connected to the gas venting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com