Detachable forklift

A technology for forklifts and forks, which is applied to the field of forklift handling tools, can solve the problems of inability to pass, unsuitable, and occupy a large area, and achieves the effect of meeting the needs of cargo transportation and being easy to handle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

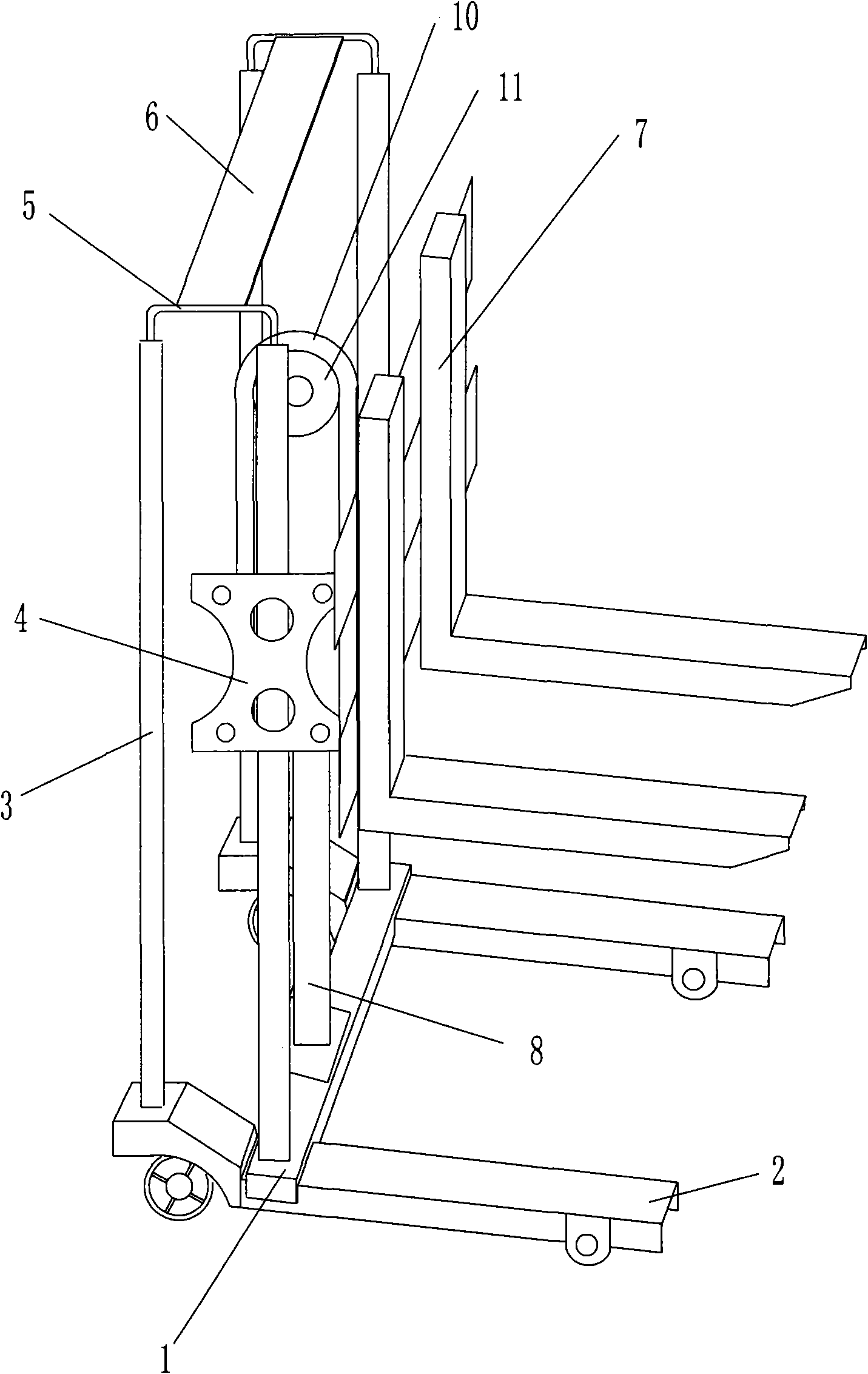

[0042] Such as figure 1 As shown, the forklift described in the present invention includes a base, and a vertical beam detachably connected with the base, the vertical beam is detachably provided with a fork frame that can move up and down along the vertical beam, and the fork frame is connected with the load The fork of the heavy object is detachably connected, and the fork is driven by a hydraulic mechanism set on the base.

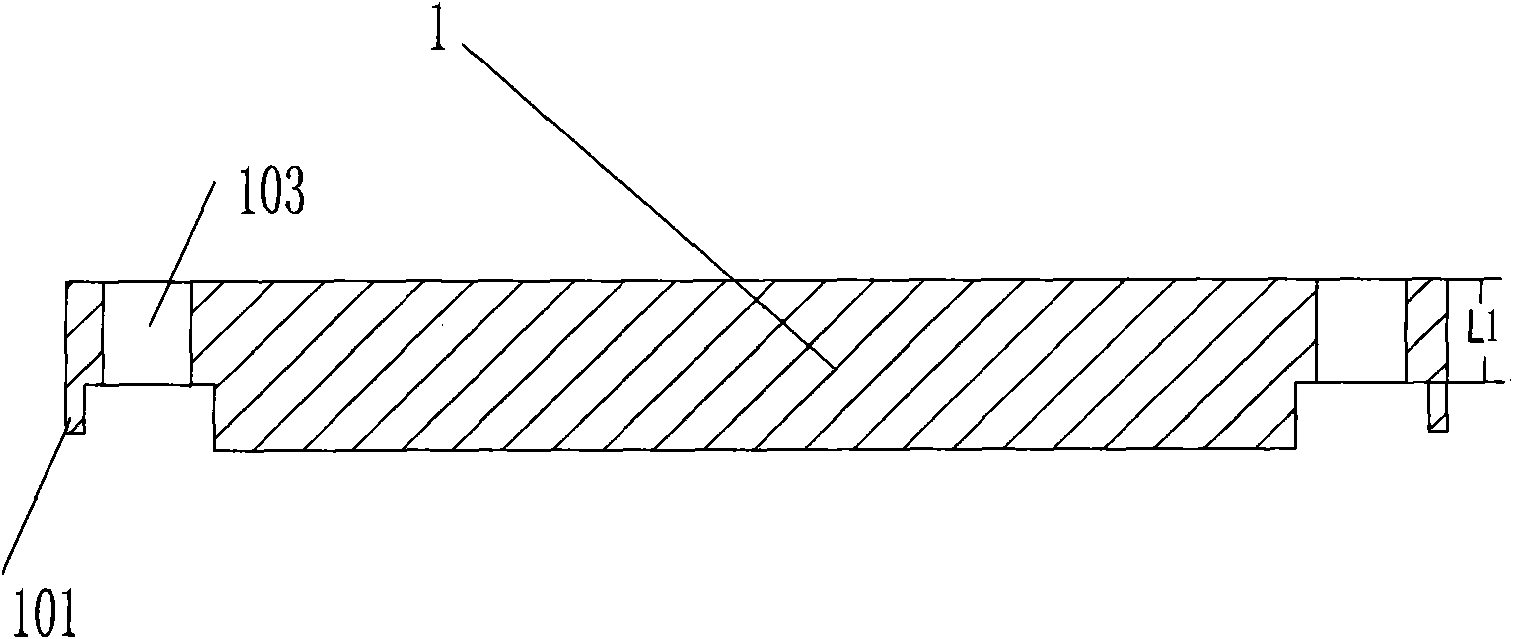

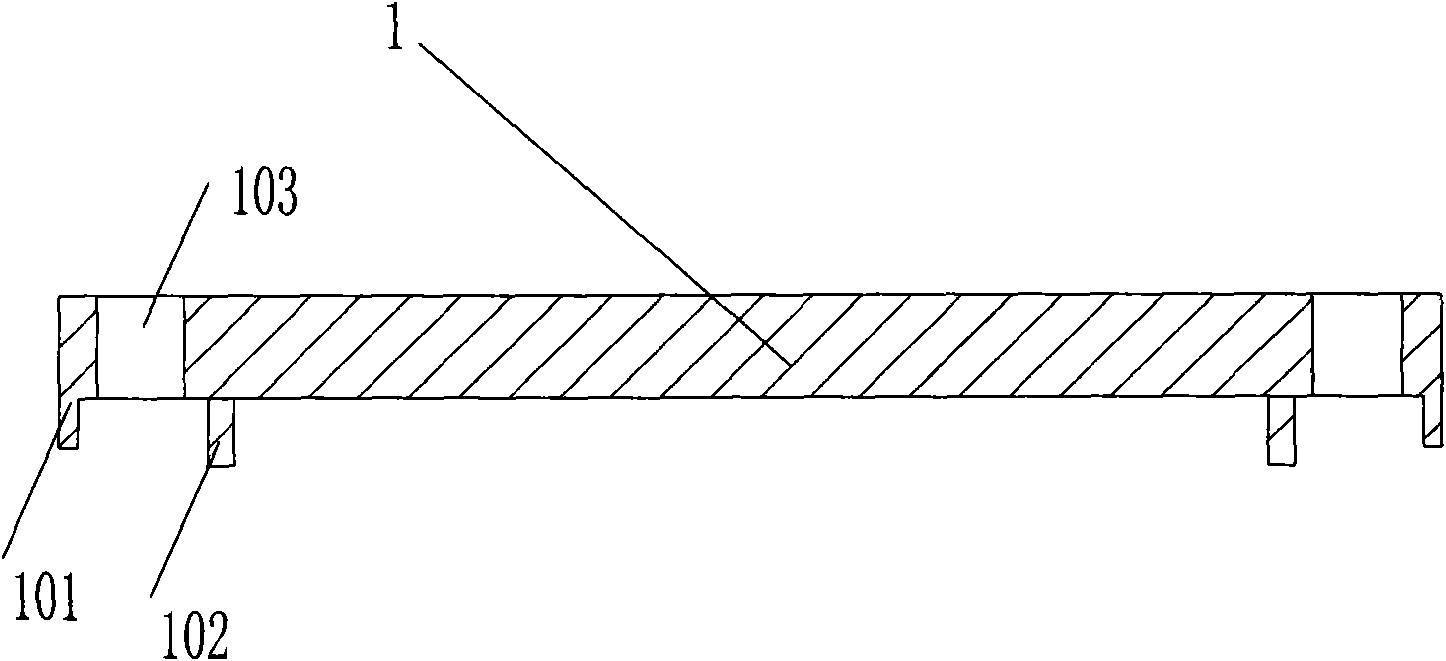

[0043] The base is composed of two beams 2 and a positioning beam 1 between the beams. At least one positioning beam 1 is arranged between the two beams 2. After assembly, the positioning beam is perpendicular to the beam. Such as Figure 2a and Figure 2b As shown, the positioning beam 1 of the forklift base is shaped steel or other steel structures, and there are through holes 103 at both ends of the positioning beam. The device 201 is matched, and after the cross beam and the positioning beam are assembled, the vertical beam positioning device on ...

Embodiment 2

[0054] Such as Figure 8 As shown, the structure of other parts of the forklift is the same as in Embodiment 1, but the vertical beam of the forklift is arranged in front of the base beam, and there is a counterweight 9 behind the vertical beam to balance the weight of the forklift. The forklift described in this embodiment, because in There is no beam in the direction of the fork extending, so when in use, when the fork is in contact with the goods, there is no obstruction in front. It is the forklift that can be closer to the goods, and the loading and unloading is more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com