High temperature strain foil performance parameter tester and test method thereof

A high-temperature strain gauge and parameter testing technology, which is used in measuring devices, using stable tension/pressure to test the strength and strength characteristics of materials, etc. High reliability and high temperature repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

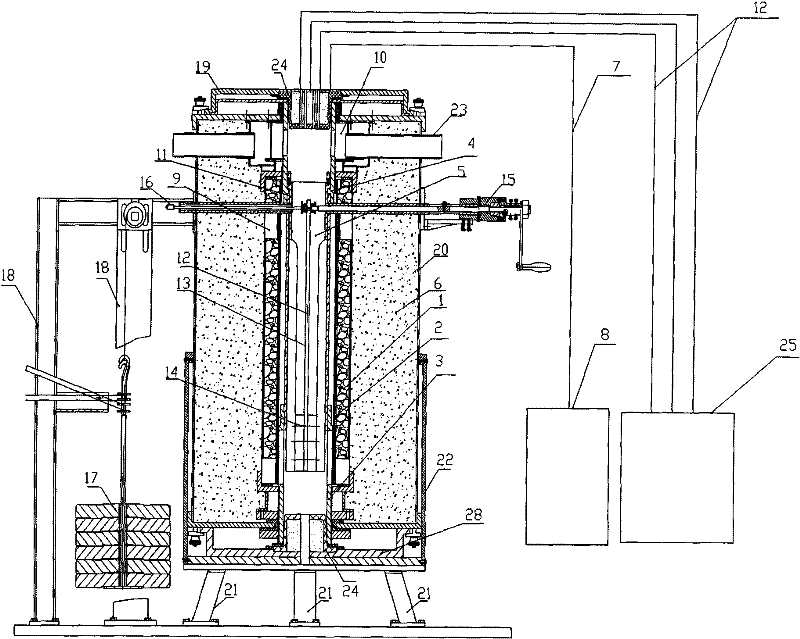

[0039] Such as figure 1 As shown, the high-temperature strain gauge performance parameter testing device of the present invention is composed of a heating system, a heat preservation system, a temperature control system, a circulation system, a support system and a loading system. The heating system is located in the center of the device and is connected to the temperature control system; a support system is installed inside the heating system, and the heat preservation system is located outside the heating system; the circulation system is connected to the heating system, and the loading system is connected to the support system. in:

[0040] Heating system: composed of ring-shaped furnace tile 1, heat shielding area 3 and furnace cavity 5, located in the center of the device; ring-shaped furnace tile 1 is made of corundum, and nickel-chromium electric furnace wire 2 is wound on the ring-shaped furnace tile 1, which is heated by electricity Reach the specified temperature; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com