Power unit support structure

A technology of power unit and support structure, applied in power plant, vibration suppression adjustment, shock absorber, etc., can solve the problems such as weakening and infeasibility of idling vibration damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

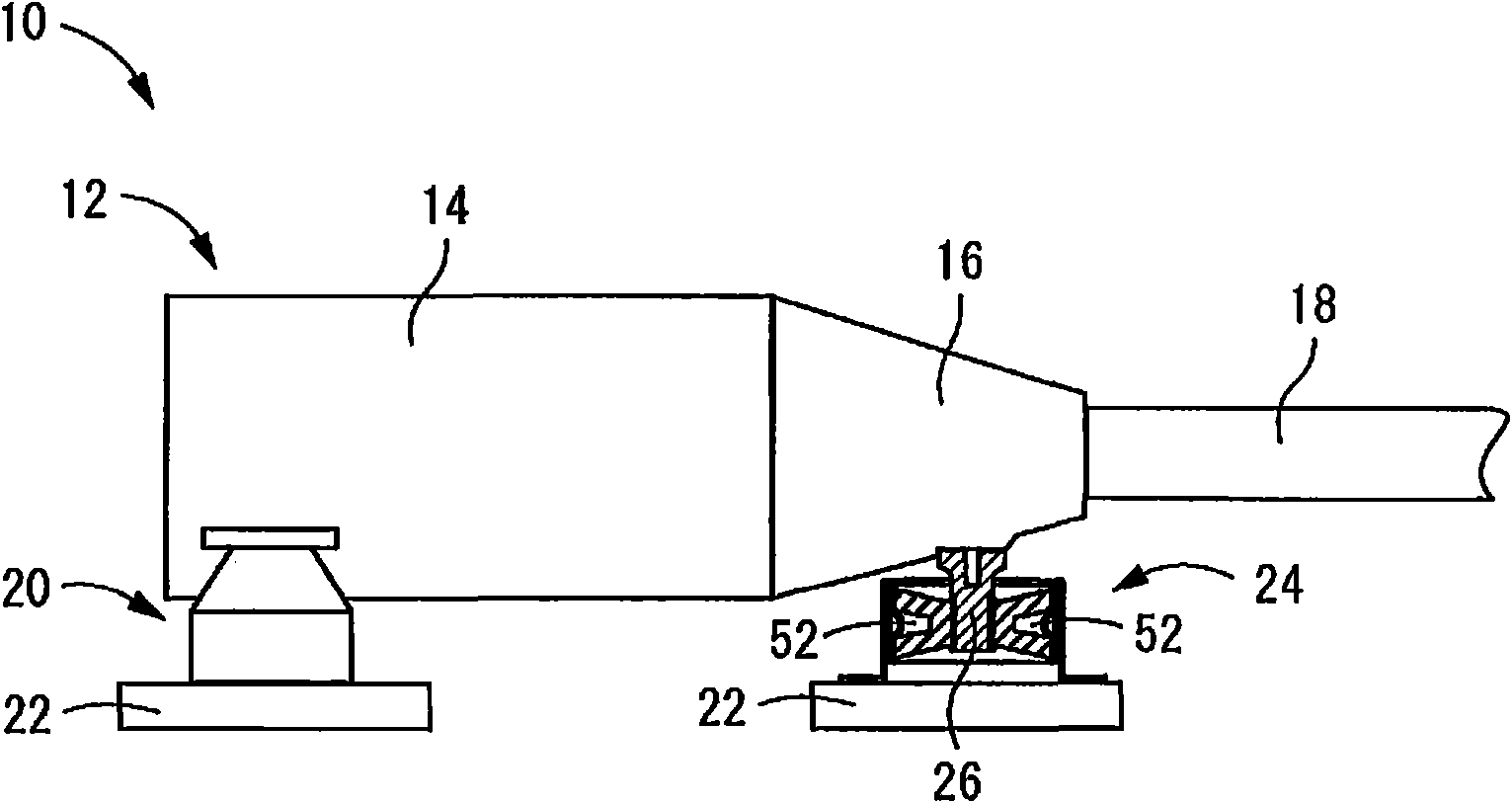

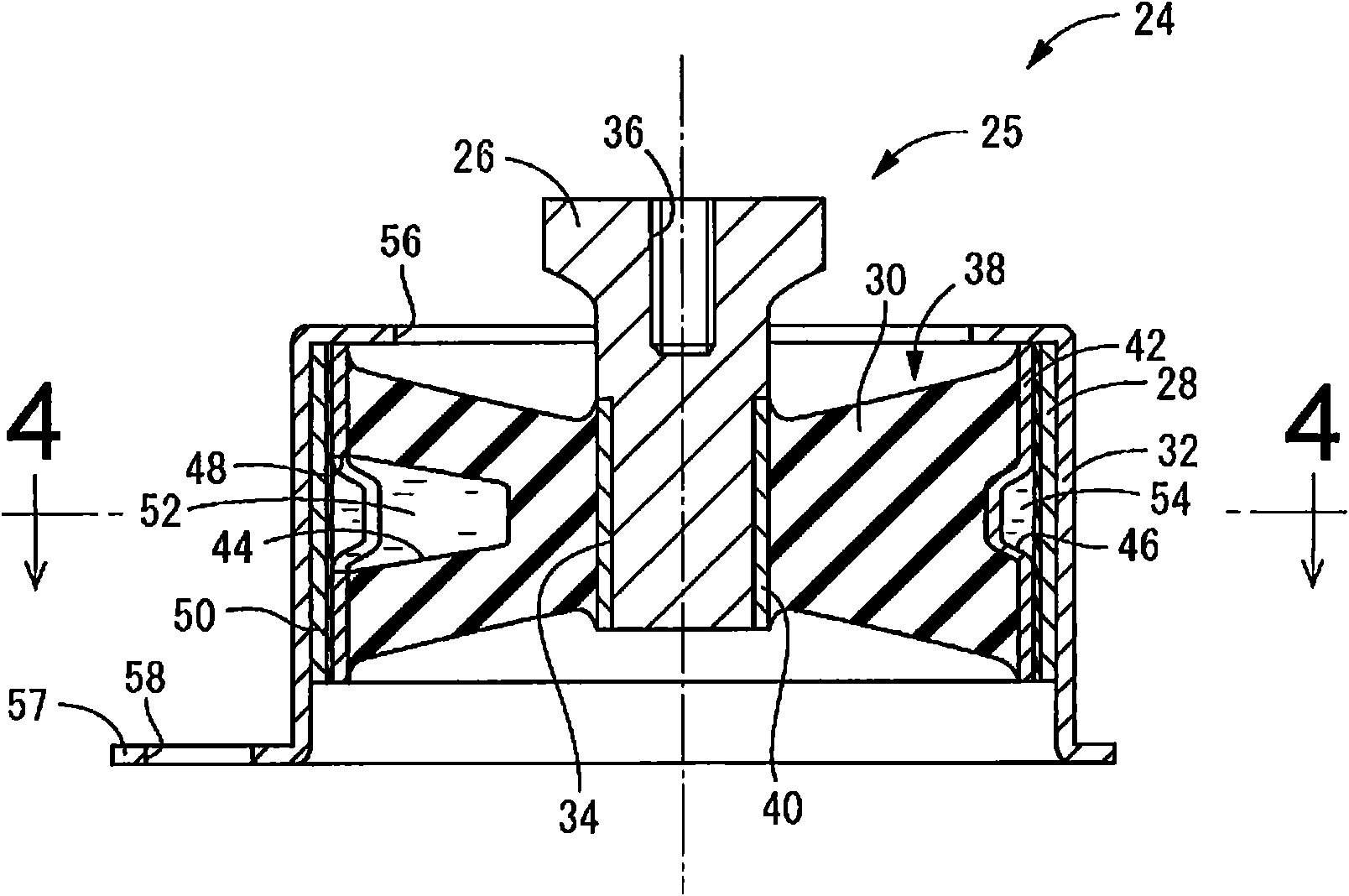

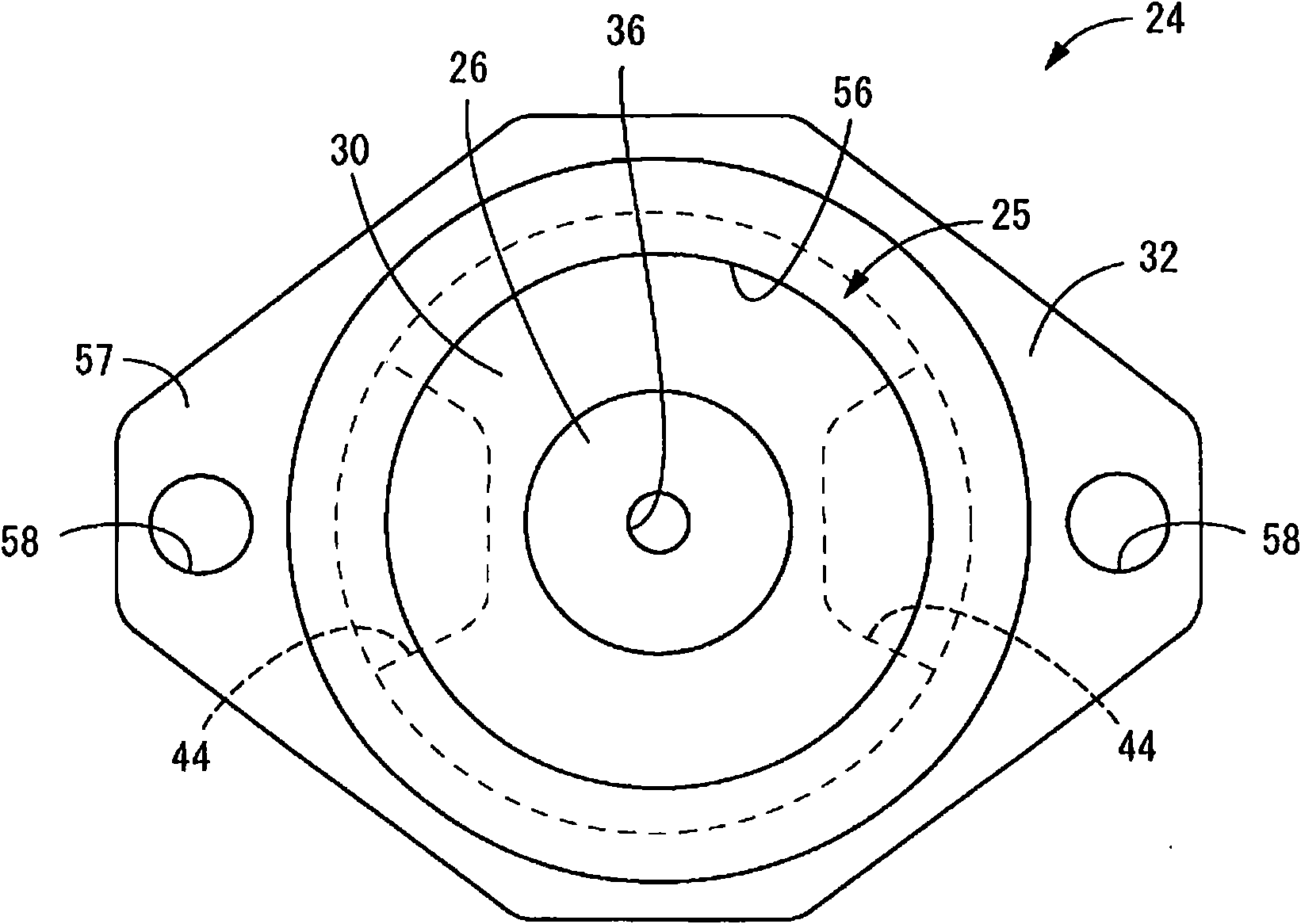

[0045] figure 1 is a side view showing the entire power unit support structure 10 according to the first embodiment of the present invention in a simplified manner. The power unit 12 is a power unit for an automobile of FR design, and the power unit 12 includes an engine unit 14 provided as an internal combustion engine and a drive train unit 16 provided as a gearbox. The output and torque generated by the engine unit 14 are adjusted by the gear train of the drive train unit 16 to a level of output and torque required to drive the vehicle, and are output to an output shaft (not shown), and then as rotational driving force via The propeller shaft 18 is transmitted from the output shaft to the drive wheels, ie the rear wheels.

[0046] To illustrate more specifically, the power unit 12 is oriented lengthwise in the vehicle fore-and-aft direction such that the propeller shaft 18 extends in a direction that is aligned with the vehicle fore-and-aft direction ( figure 1 The left a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com