Power transmission

A technology of power transmission system and transmission device, which is applied in the field of power transmission system to achieve the effect of small friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

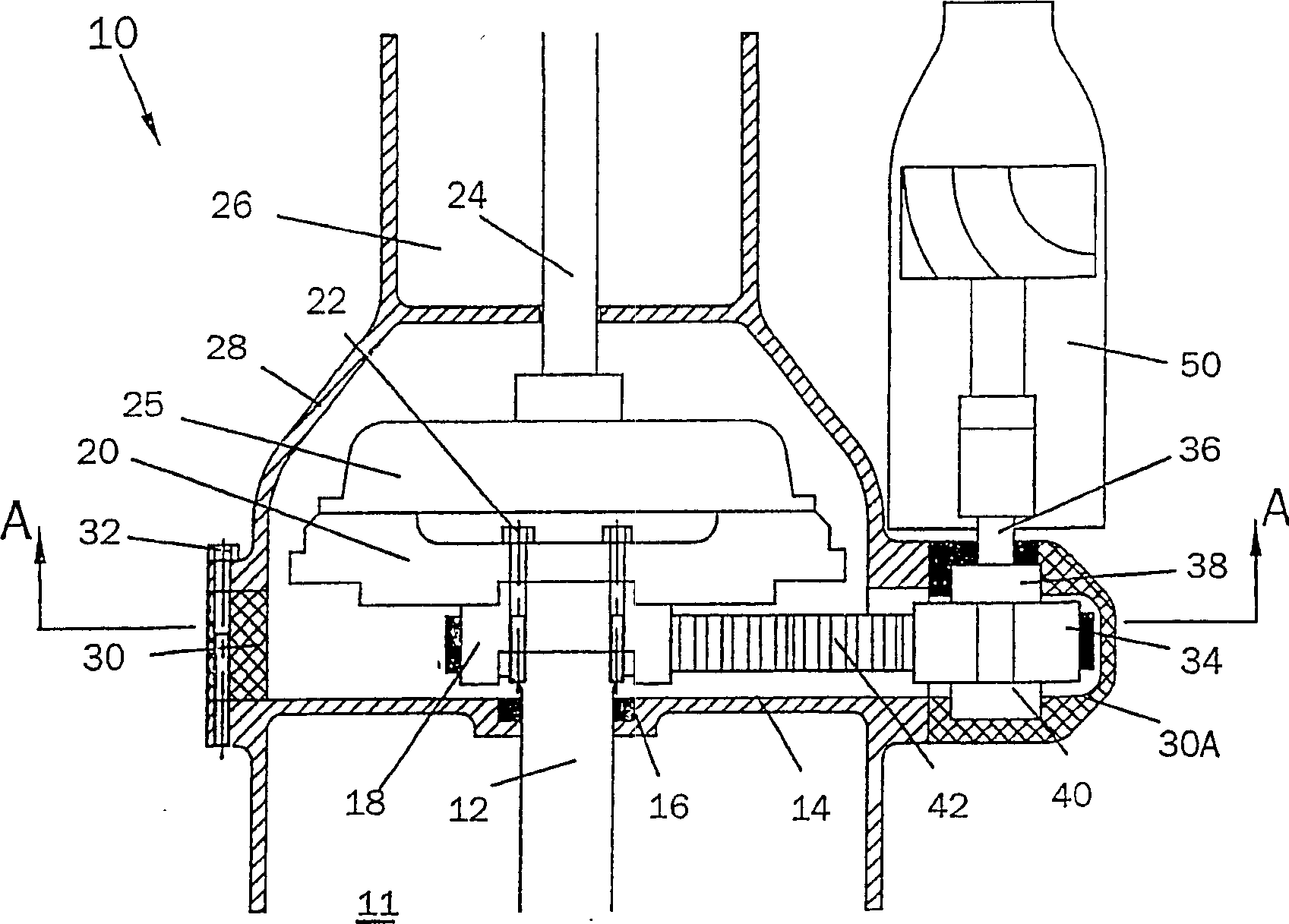

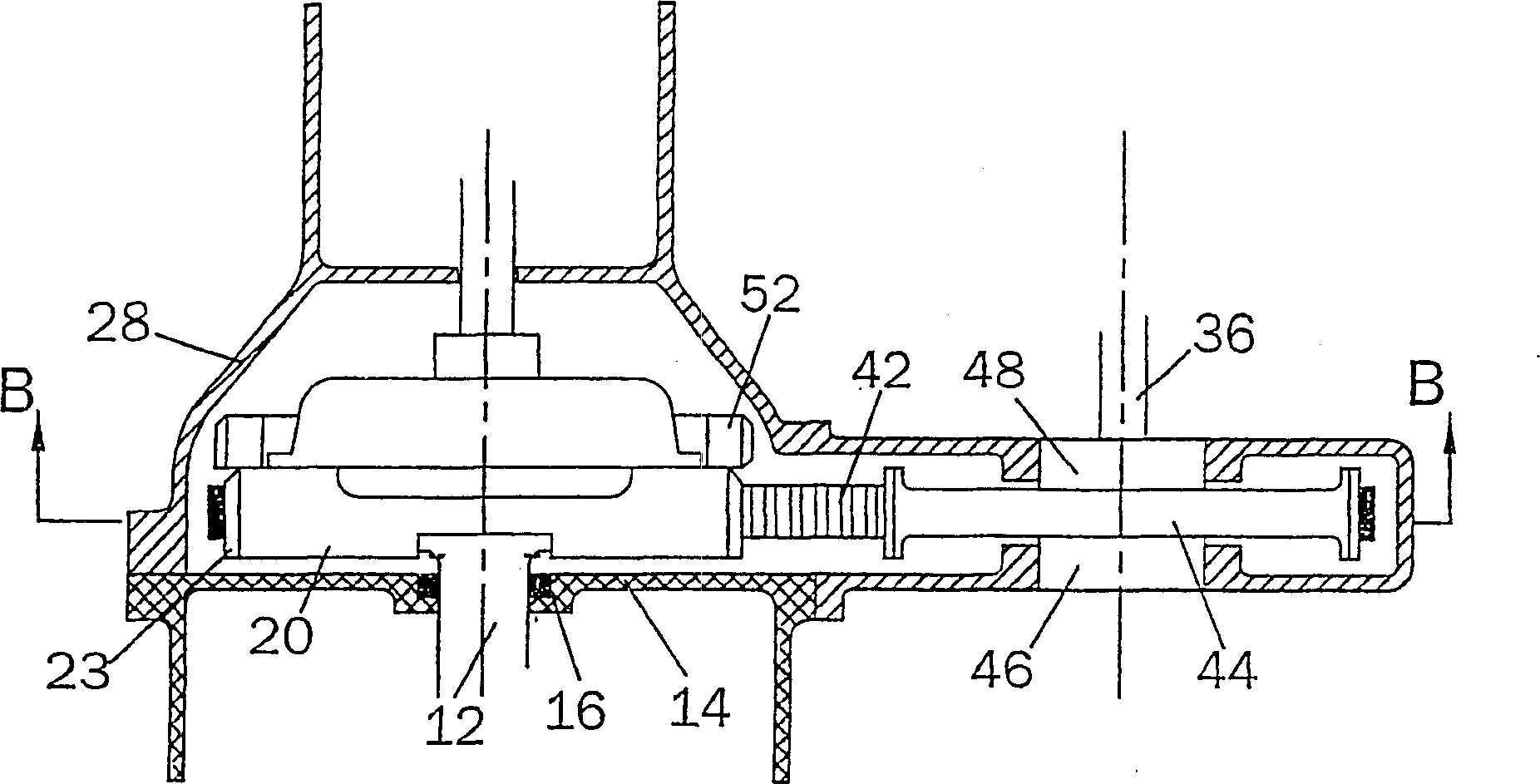

[0021] first as figure 1 and figure 2 As shown, the first embodiment of the powertrain of the present invention includes an engine 11 and a transmission 26 in line with the crankshaft 12 of the engine. The engine and transmission provide drive to at least the rear wheels (not shown) of the amphibian using a conventional differential (not shown). The power take-off 10 provides drive to the vehicle's water propulsion means, such as a water jet 50 .

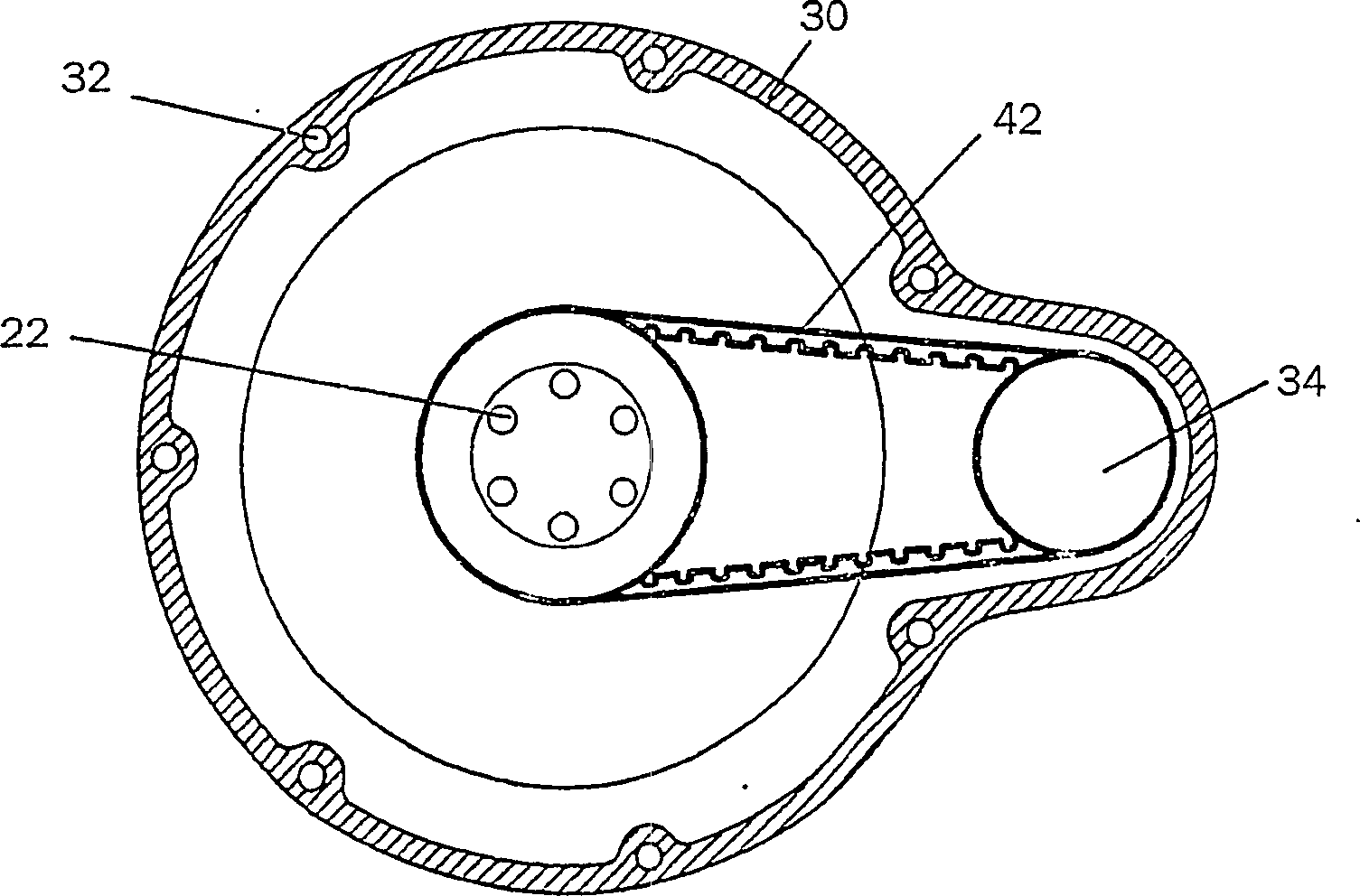

[0022] The crankshaft 12 of the engine passes through a hole in the end of the engine casing 14 . A seal 16 is arranged in the hole to realize the sealing between the crankshaft 12 and the engine casing 14 . Drive sprocket 18 and flywheel 20 are mounted on the end of crankshaft 12 outside of engine casing 14 and are fixedly secured to crankshaft 12 by a turn of bolts 22 . A drive sprocket 18 is fixed between the end of the crankshaft 12 and a flywheel 20 . A clutch 25 is mounted on the face of the flywheel 20 in a conventional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com