Longitudinal engine mount installation structure

A technology of engine suspension and installation structure, which is applied in the direction of power device, transportation and packaging, jet propulsion device, etc., can solve the problems of restricting production rhythm, slow production rhythm, difficult assembly, etc., achieve shortening production rhythm, improve production efficiency, Optimize the effect of suspension structure and installation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

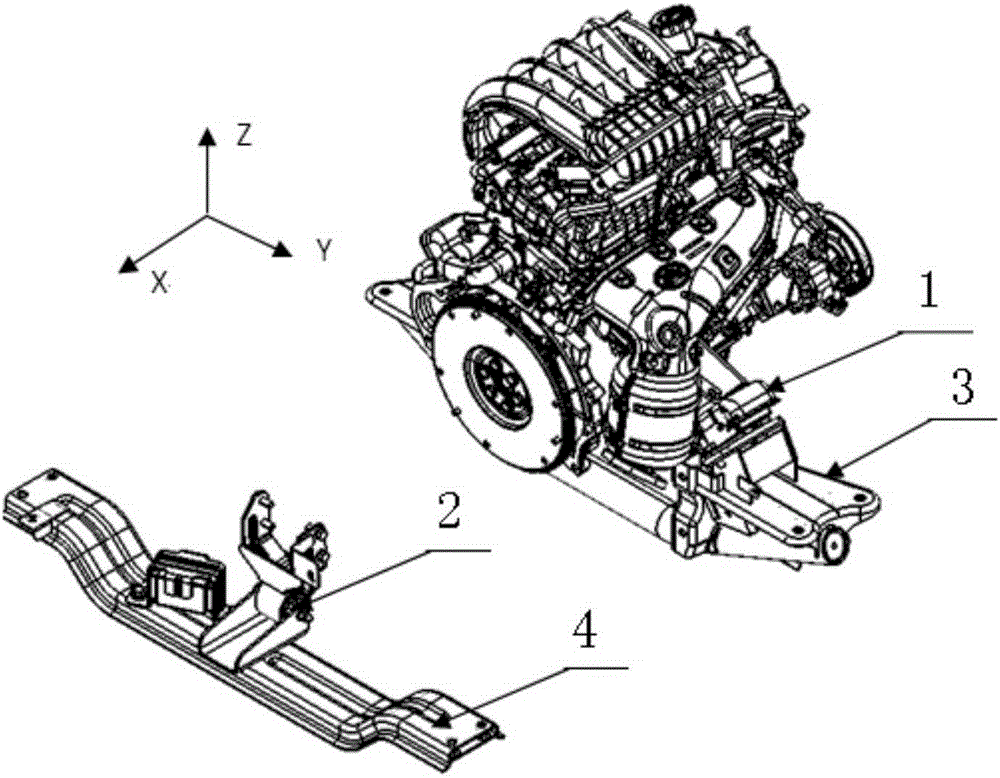

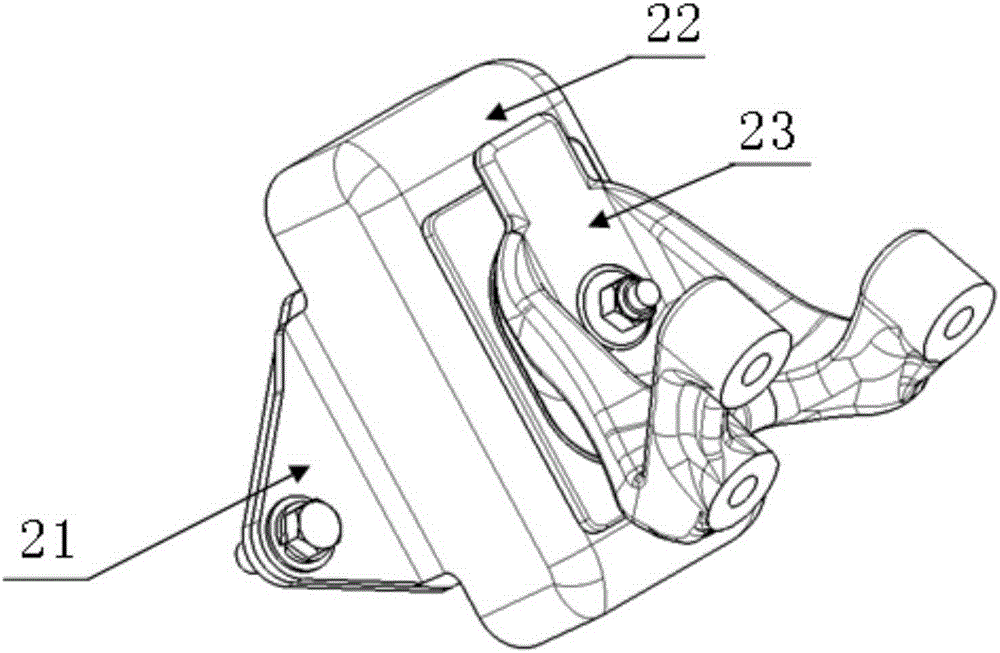

[0036] The invention provides a vertical engine suspension installation structure, such as Figure 6 to Figure 10 As shown, it includes an engine mount rubber body 01, an engine mount cover plate 02 and a transition structure 03; there is an included angle of a set angle between the engine mount rubber body 01 and the horizontal plane; the function of the included angle is to ensure The engine mount is oblique mount.

[0037] In the documents of this application, all references to the X direction, Y direction and Z direction are the coordinate system directions, wherein the Z direction is the direction perpendicular to the X direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com