Terminal protecting component of electric compressor

A technology for electric compressors and protective components, which is applied in the direction of machines/engines, pump components, mechanical equipment, etc. It can solve problems such as narrow intervals, hindering the bypass operation of the cord group 20, and difficulty in performing it, and achieves the effect of preventing poor insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention will be described below with reference to the drawings.

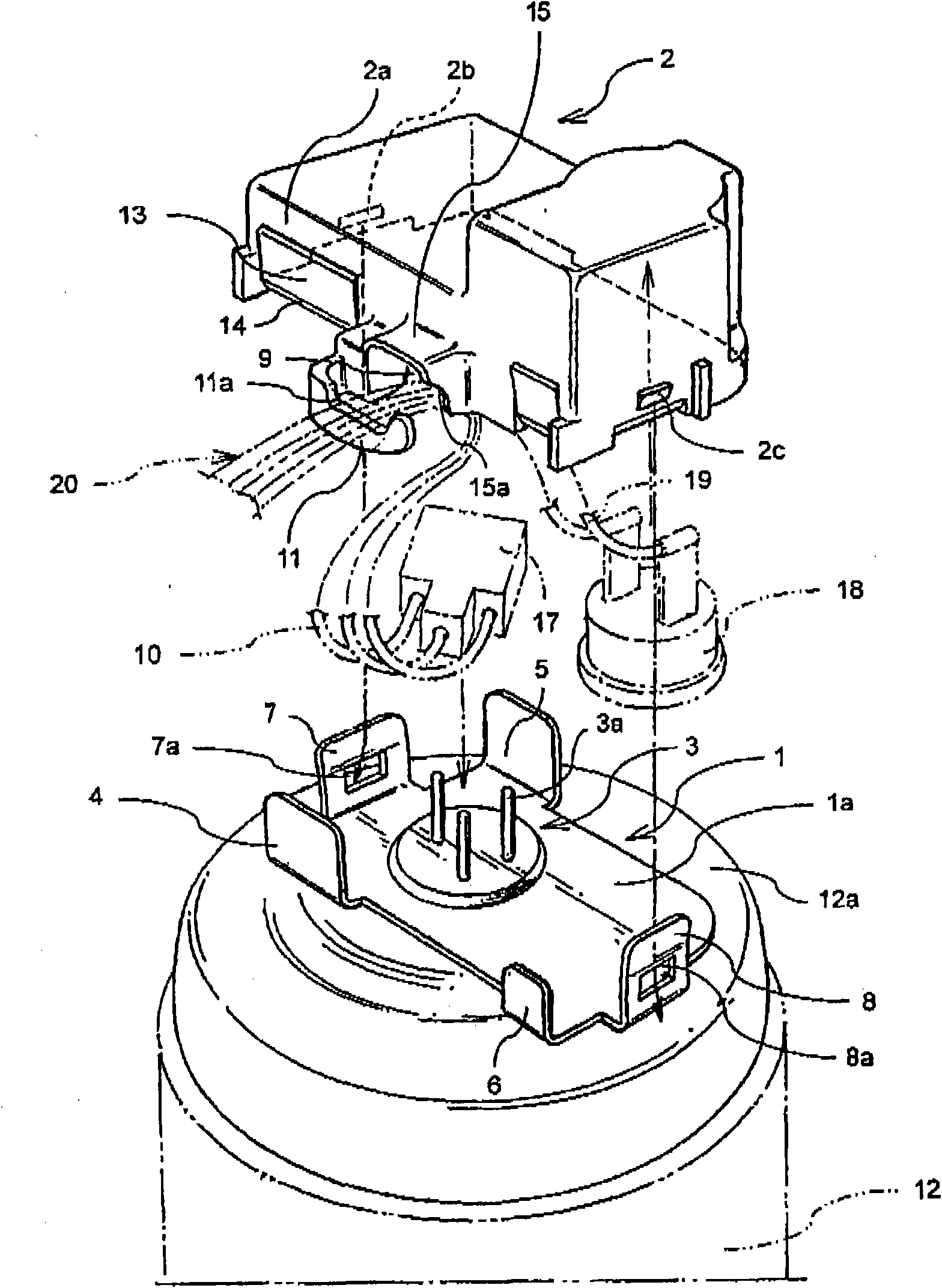

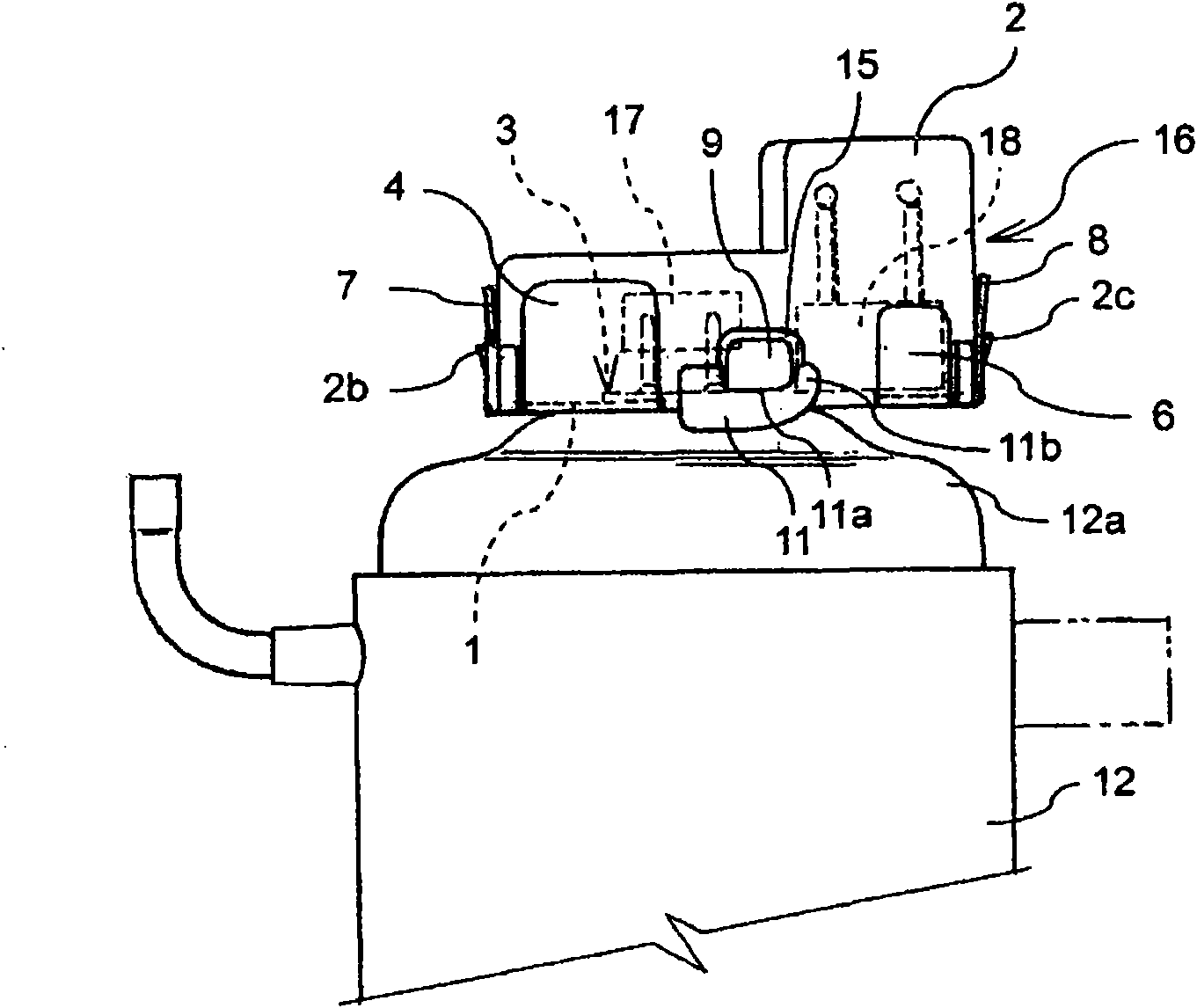

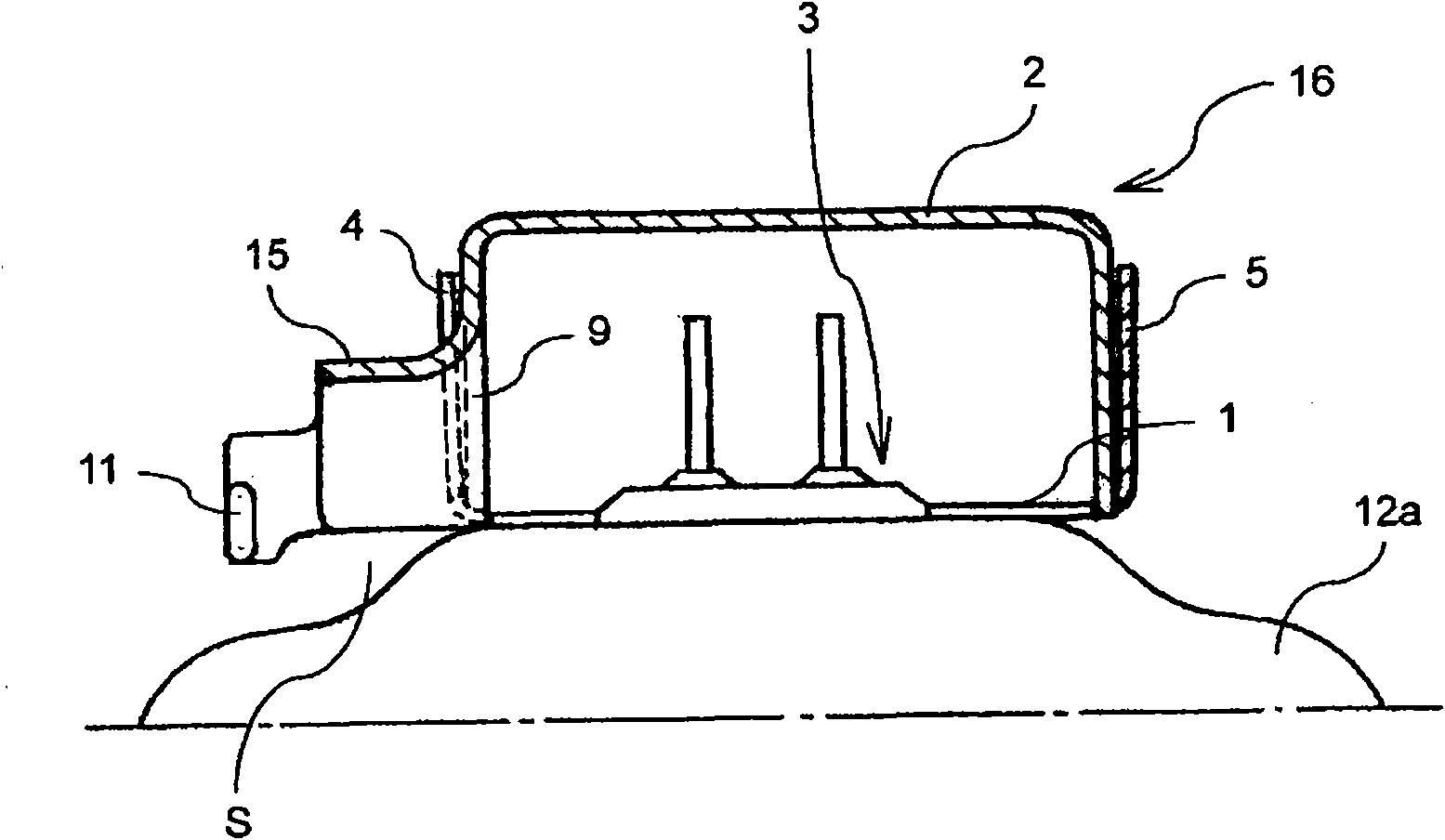

[0048] figure 1 It is a schematic exploded perspective view which shows embodiment of the terminal protection member of the electric compressor concerning this invention. right with Figure 6 In the conventional example shown, substantially the same members are denoted by the same reference numerals as those described above.

[0049] exist figure 1 Among them, 1 is a terminal guard made of steel plate, which penetrates the terminal 3 fixed to the top of the lid body 12a of the airtight container 12 and is attached to the lid body 12a. The side portion of the base plate 1a of the terminal guard 1 is vertically provided with blocking pieces 4, 5, and the side portion on the same side as the blocking piece 4 is vertically provided with a small blocking piece 6, and is vertically opposed at the end. Locking pieces 7, 8 are provided, and these locking pieces 7, 8 are formed wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap