Manufacturing method of minitype acoustical generator

A production method and sound generator technology, applied in the direction of sensors, electrical components, etc., can solve problems such as air leakage, achieve the effects of reducing low-frequency distortion, preventing the diaphragm from floating, and improving acoustic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

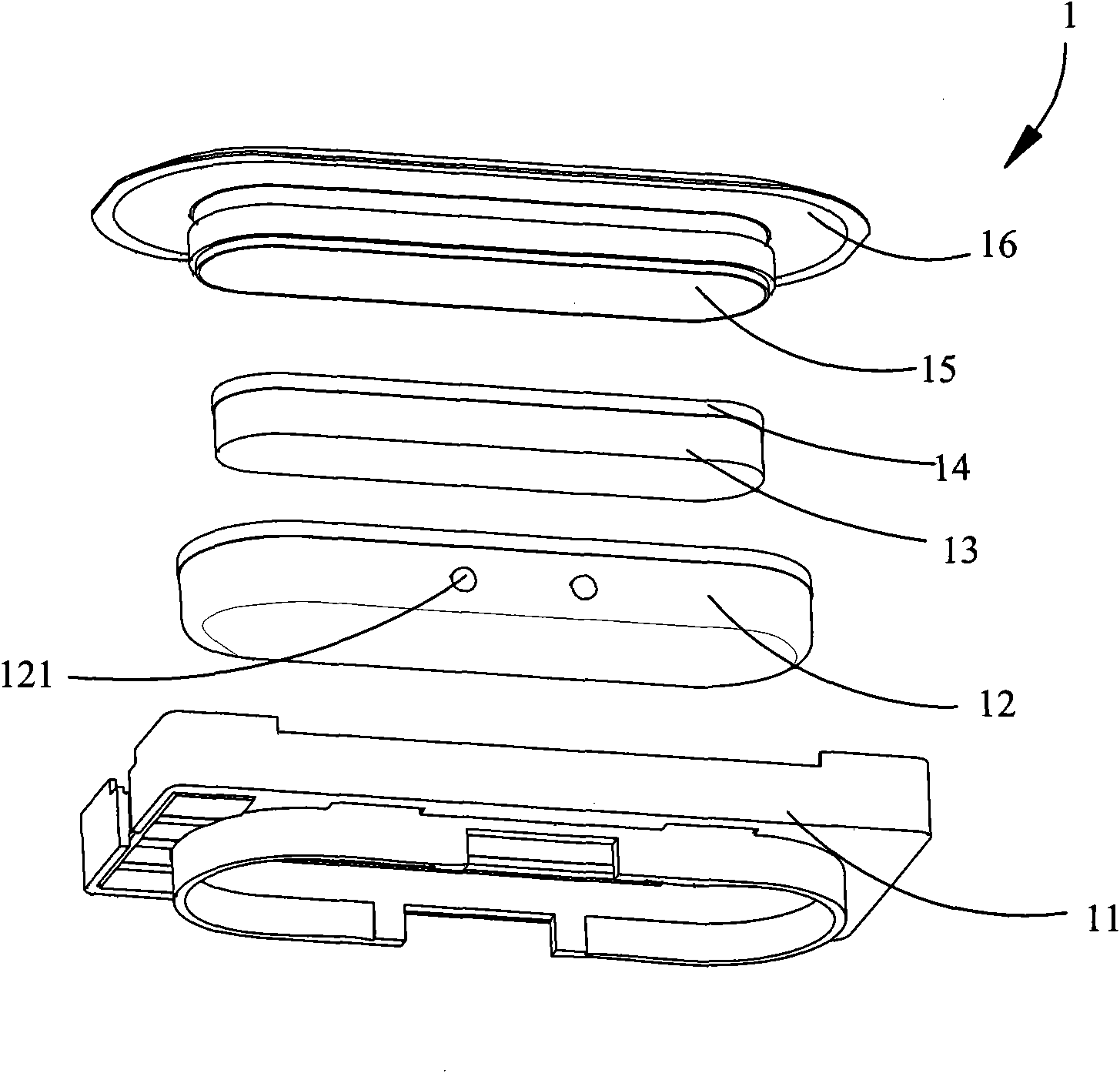

[0020] see figure 1 , the micro-sounding device 1 of the present invention is mainly applied to portable consumer electronic products such as mobile phones, to send out sound prompts.

[0021] Generally speaking, the miniature sound-generating device mainly includes a bowl-shaped base, an upper cover connected to the base and provided with a sound hole, and the base and the upper cover form a cavity. The cavity is provided with a permanent magnet and a pole piece housed in the base and forming a magnetic gap with the base, a diaphragm adjacent to the upper cover, a voice coil connected with the diaphragm and suspended in the magnetic gap, A circuit board is arranged on the outside of the base to realize connection with the external circuit, and the incoming and outgoing lines of the voice coil pass through the holes provided on the base to connect with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com