Structural element for a functional member of a headbox in a web-manufacturing machine, functional member and headbox made thereof, and associated methods

A technology for structural elements and manufacturing machines, applied in the wet end of paper machines, paper machines, paper making, etc., can solve problems such as interference with paper formation, and achieve the effect of reducing assembly time and weight, cost saving, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

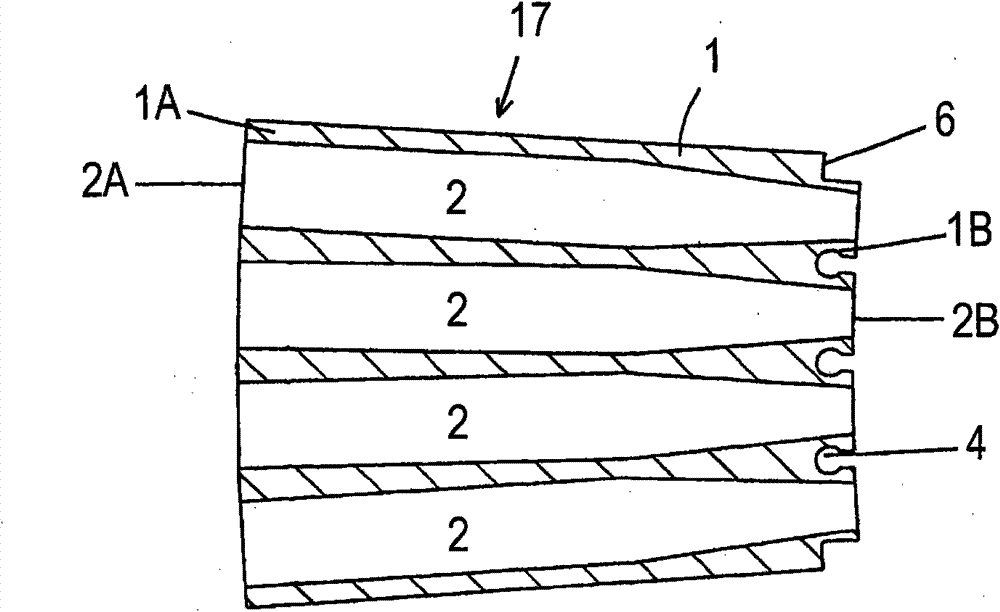

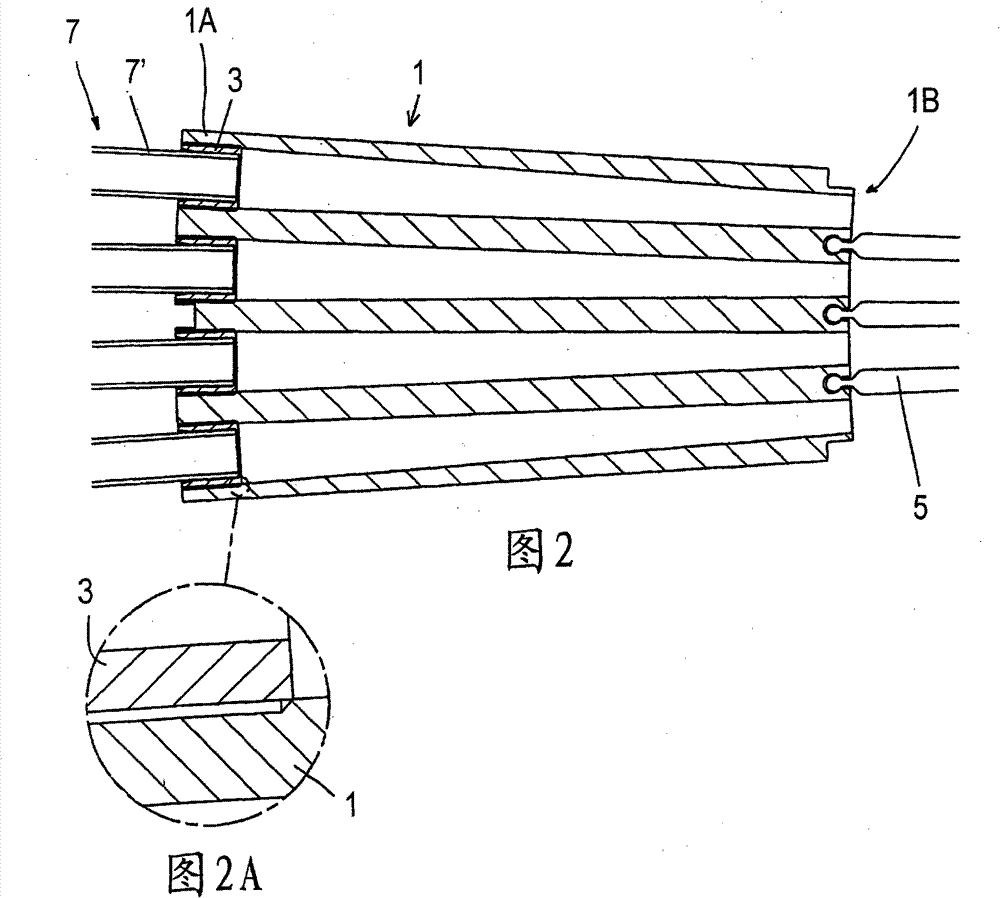

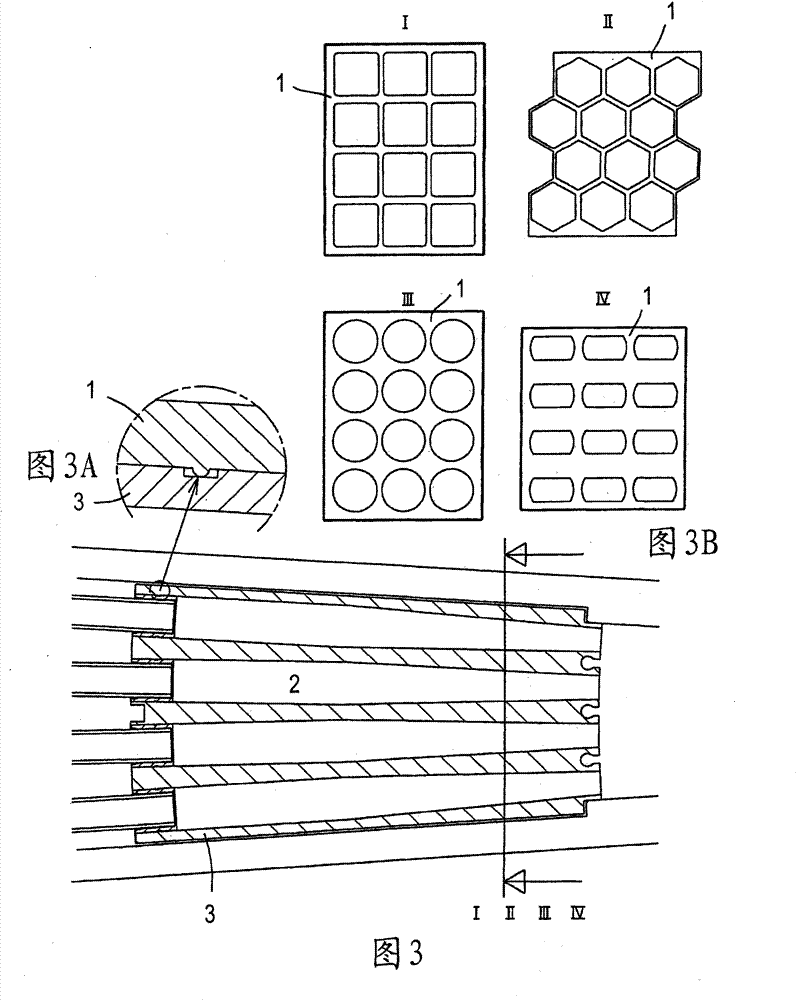

[0046] figure 1 A longitudinal sectional view of a structural element 17 according to a first embodiment of the present invention is shown. The structural element 17 comprises a solid monolithic block 1 having a plurality of channels 2 passing through the monolithic block 1 from the upstream end 1A to the downstream end 1B of the structural element 17 . The channels 2 define the pulp flow path and are arranged in rows and columns. For example, a monolithic block 1 may comprise four rows of channels 2, with three channels in each row, as image 3 and Figure 3B as disclosed.

[0047] The structural element 17 is designed as part of a turbulence generator unit, for example as Figure 8 as disclosed in. exist Figure 8 middle, figure 1 Three structural elements 17A, 17B and 17C of the type disclosed in are arranged side by side to form a turbulence generator unit 11 in the headbox 10 . The structural elements 17A, 17B and 17C are arranged such that the upstream end 1A and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com