Clutch body and synchronizer ring for a synchronization device

A technology of synchronous device and clutch body, applied in clutches, mechanically driven clutches, friction linings, etc., can solve problems such as mechanical weakening and clutch body cracks, and achieve the best cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

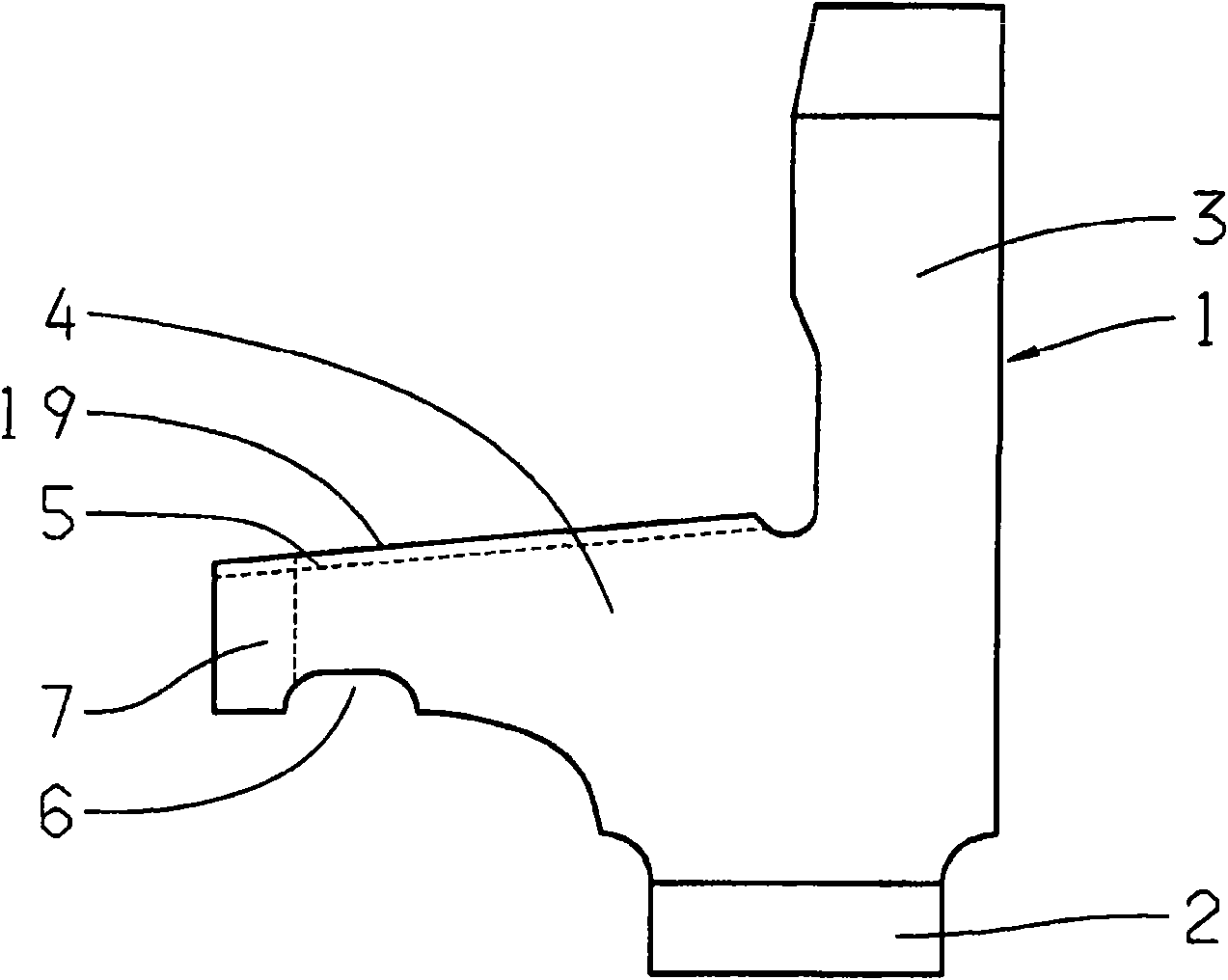

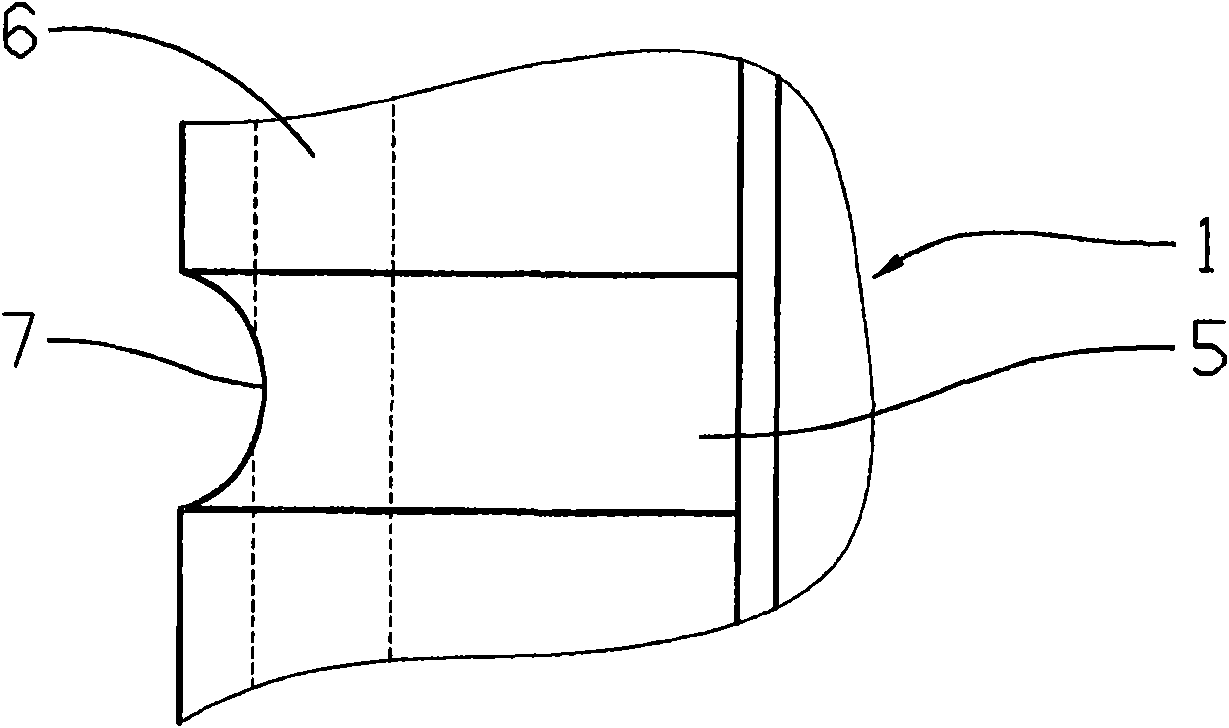

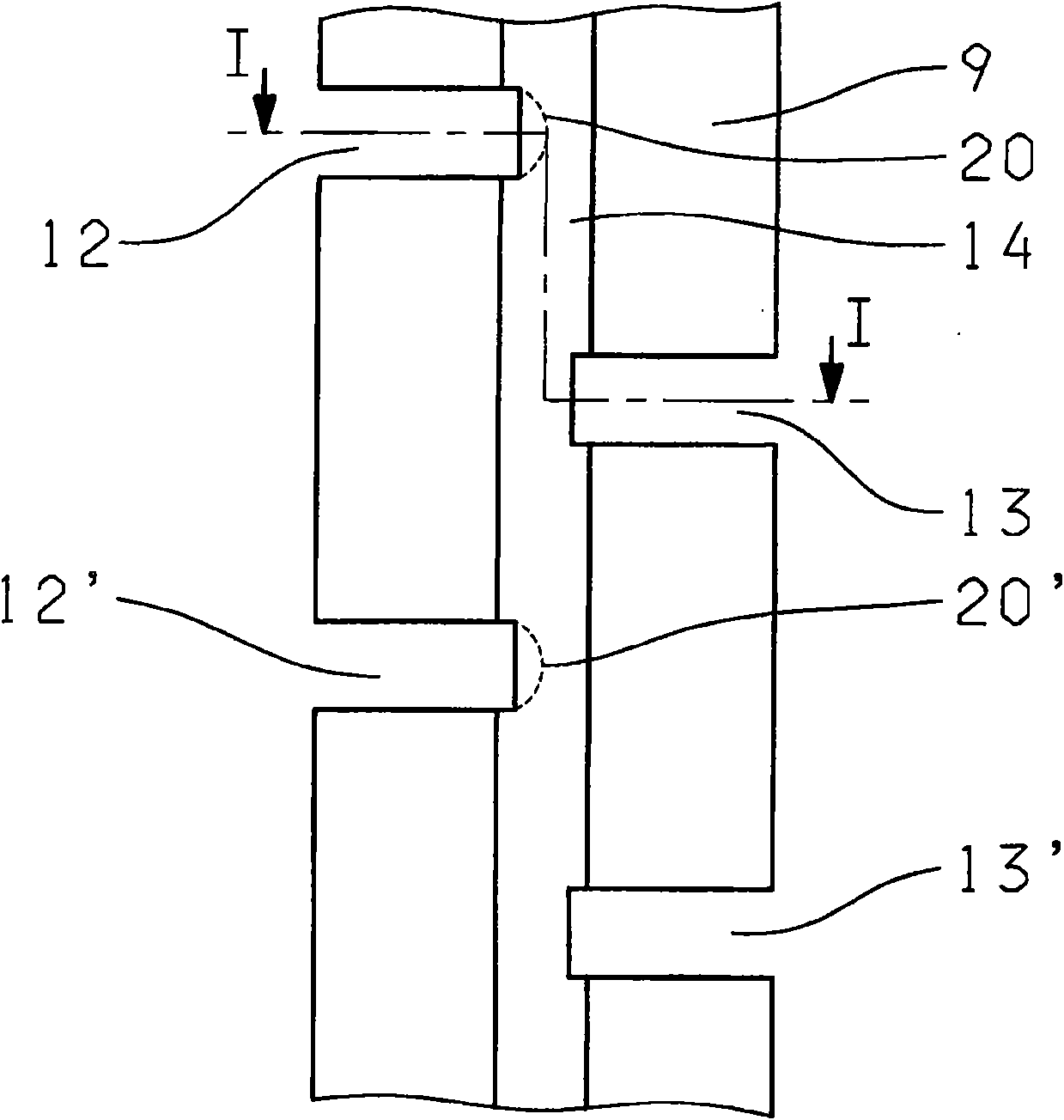

[0044] figure 1 with 2 A feasible implementation form of a clutch body for a synchronizing device proposed by the present invention is shown in FIG. Figure 3 to 10 Shows the different implementation forms of the synchronization ring for the synchronization device proposed by the present invention.

[0045] Figure 7 The synchronizing device shown only partially in is usually used for synchronizing an idler gear on one shaft of an automobile gearbox, and it includes at least one synchronizing ring 8 and at least one clutch body 1. The clutch body 1 is positively connected via the toothing 2 to an idler gear of a shaft, not shown in detail, which is to be synchronized. The synchronizing ring 8, regardless of the selected embodiment, can be connected in a form-locking manner to a connecting sleeve, which in turn is connected to the shaft of the automobile gearbox via a synchronizing body 15 in a rotationally fixed manner. In order to synchronize the idler gear, the synchronizing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com