Flat-pushing loading and unloading printing screen plate device of oval decorating machine

A printing machine and oval-shaped technology, which is applied in the field of flat-push loading and unloading printing screen devices of oval printing machines, can solve the problems of complicated procedures, long time consumption, and low accuracy of plate alignment, so as to overcome complicated procedures and improve work efficiency. The effect of accuracy and equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

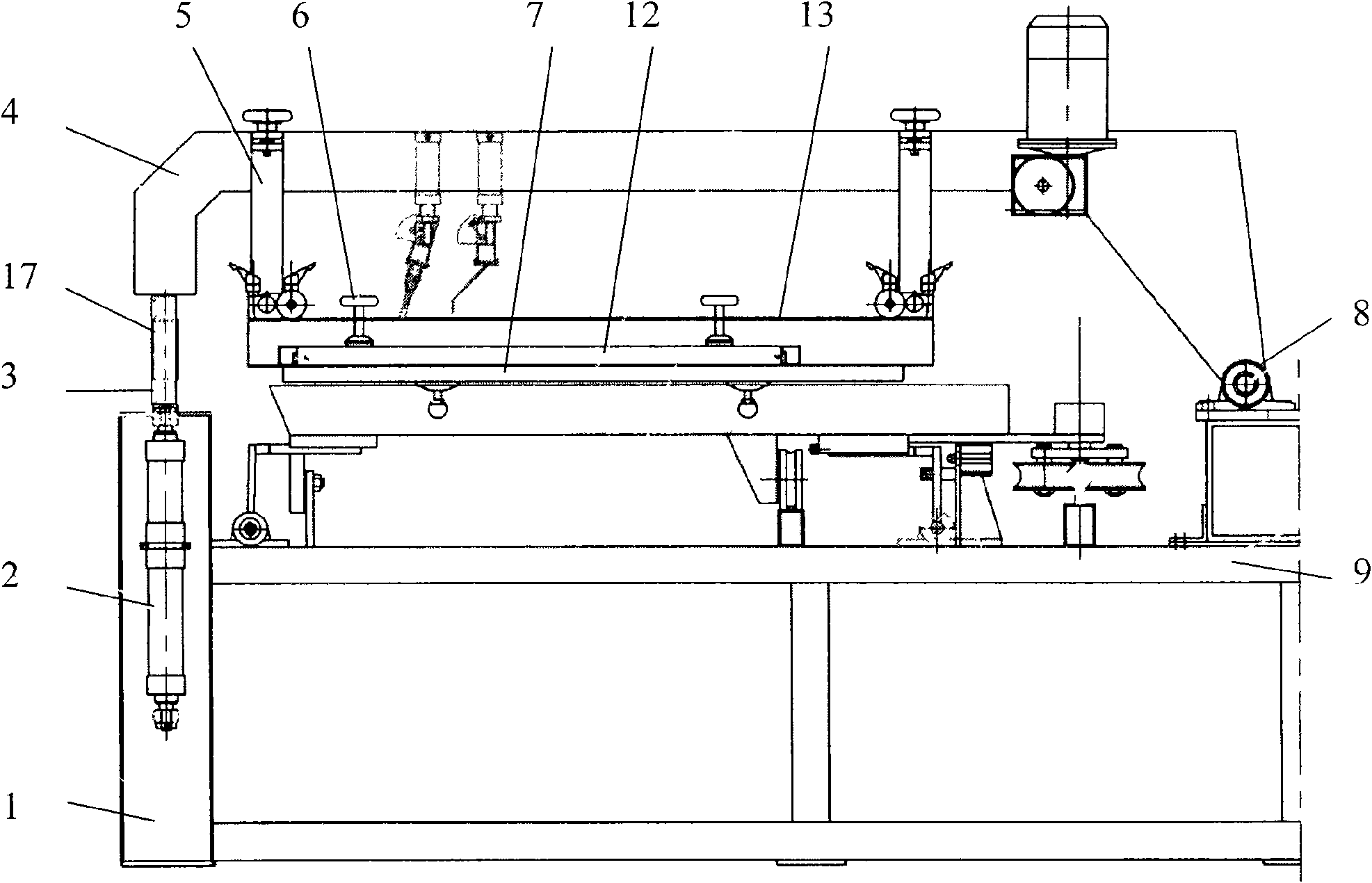

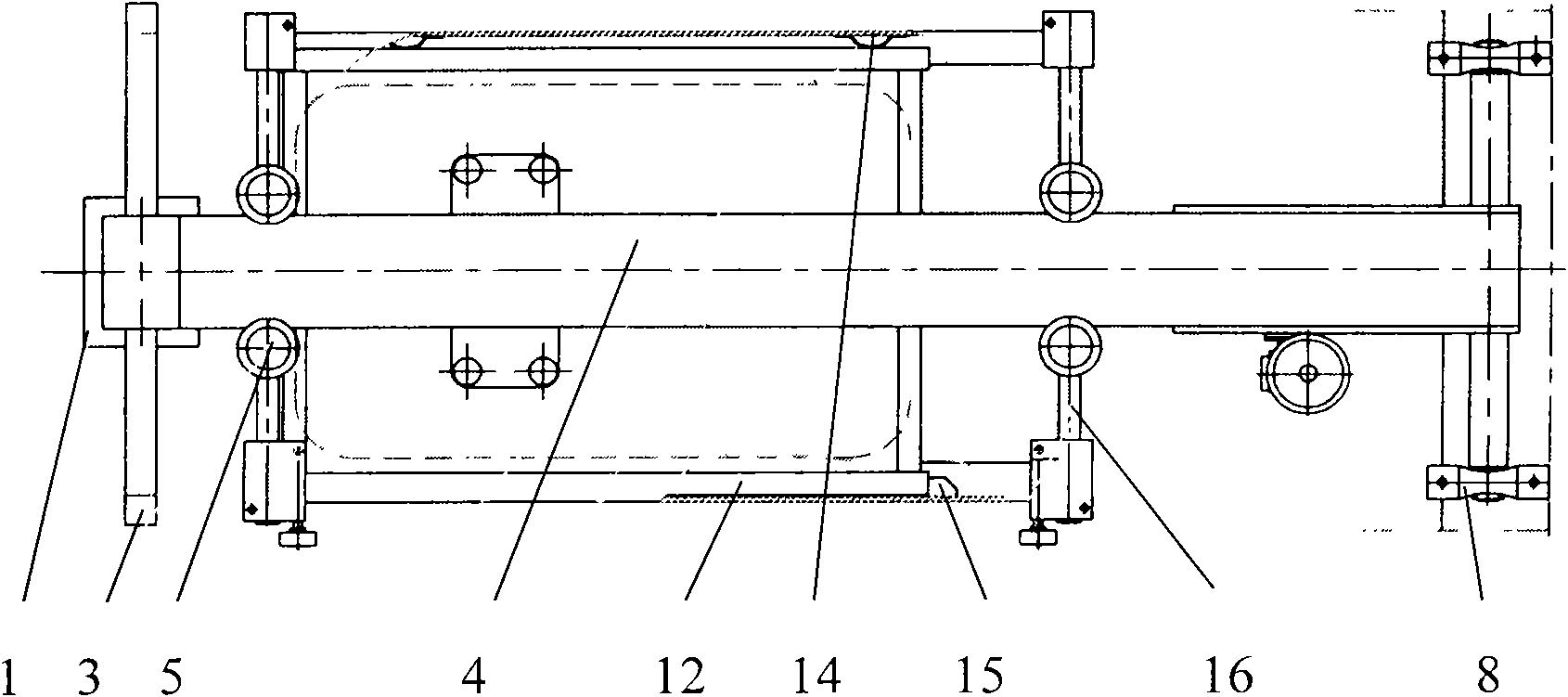

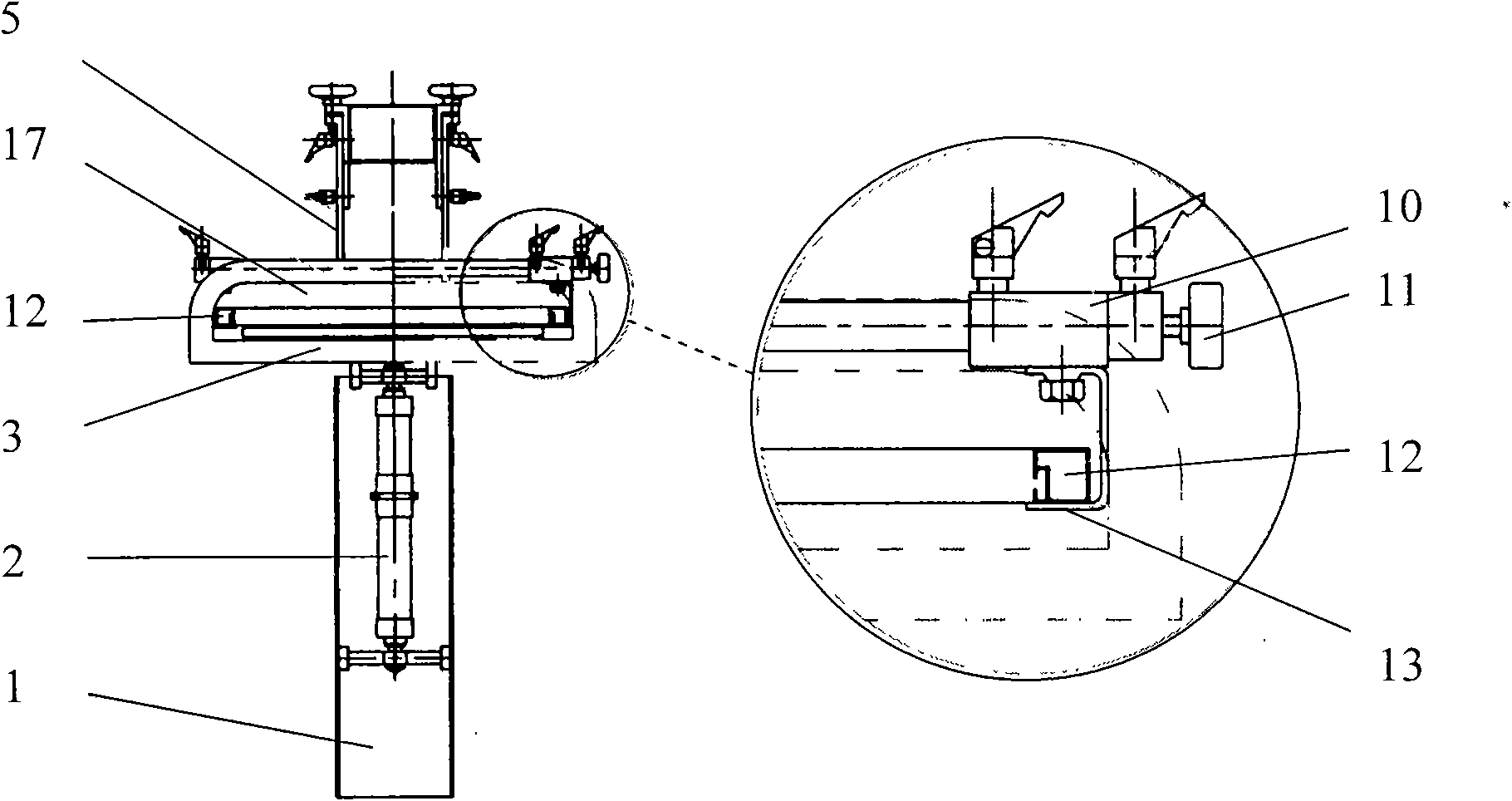

[0018] like figure 1 figure 2 image 3 As shown, the flat push type loading and unloading printing screen device of the oval printing machine includes a frame 9, a printing beam 4, a linkage frame 3, a jacking cylinder for wiping the screen 2, and a screen supporting channel steel 13; the linkage frame 3 is fixed on On the printing beam 4, the screen plate supporting channel 13 is equipped with a screen plate 12; one side of the frame 9 is provided with a side column 1, and the lifting cylinder 2 is installed in the side column 1; the left end of the printing beam 4 passes through the linkage frame 3 is connected with the cylinder 2 for jacking up and wiping the screen, and the right end of the printing beam 4 is connected with the frame 9 through the rotary shaft 8; The lower end is fixed with a connecting shaft 16, on which a fine-tuning mechanism 10 is arranged, the fine-tuning mechanism 10 is connected with the screen support channel steel 13, the fine-tuning mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com