Wafer processing method

A chip processing, chip technology, applied in the direction of stone processing equipment, laser welding equipment, electrical components, etc., can solve uneconomical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

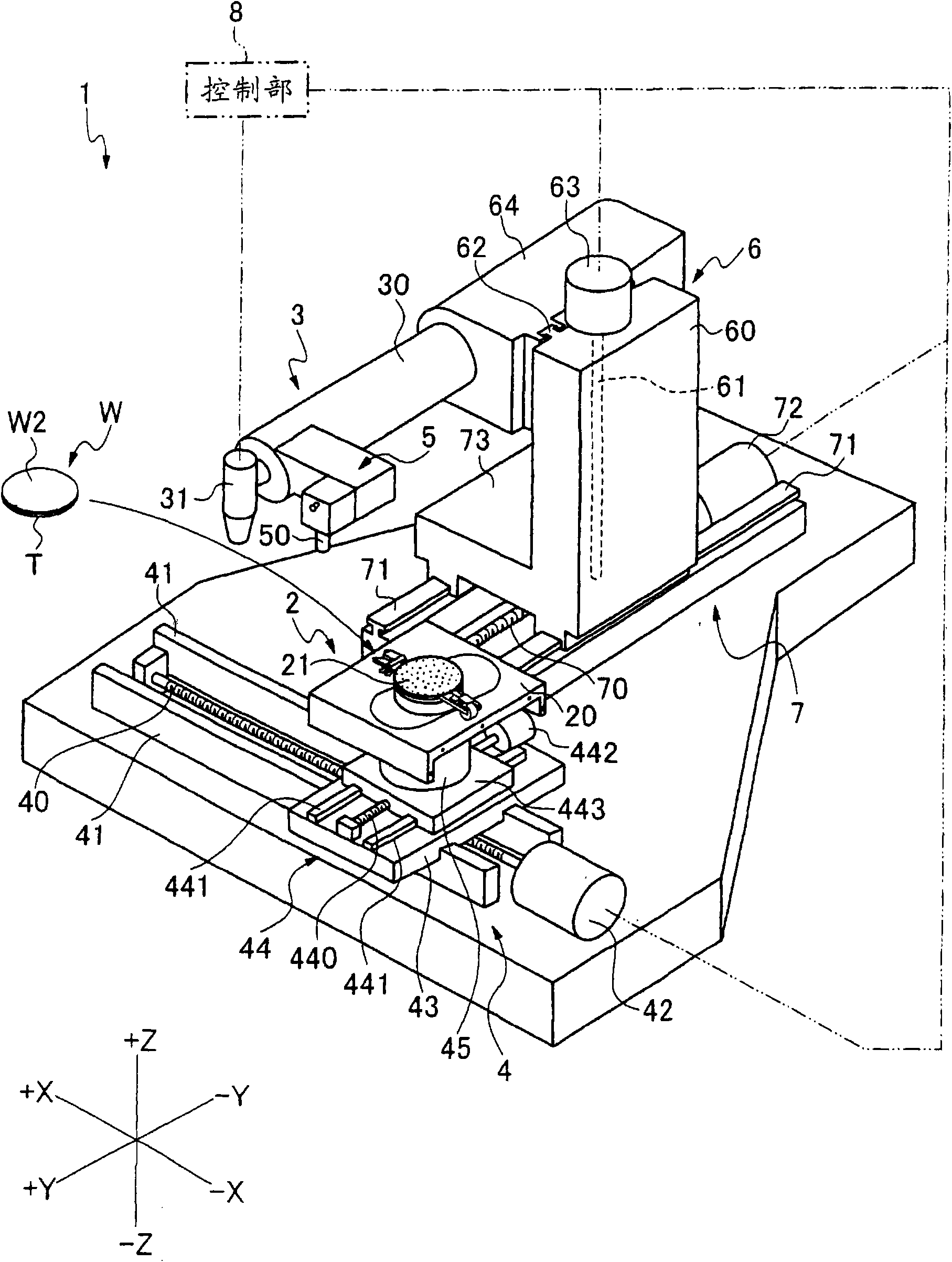

[0021] figure 1 The shown laser processing apparatus 1 is an apparatus capable of processing a wafer by irradiating laser light to form a degenerated layer inside it, and the laser processing apparatus 1 includes: a chuck table 2 that holds a wafer as an object to be processed and a laser irradiation member 3 for irradiating the workpiece held on the chuck table 2 with laser light for processing.

[0022] The chuck table 2 is subjected to machining feeding in the X-axis direction by the machining feeding member 4 . The processing feed member 4 is a member for processing the chuck table 2 and the laser irradiation member 3 in the direction of the X-axis, and the processing feed member 4 includes a ball screw 40 arranged on the X-axis. direction; a pair of guide rails 41, which are arranged in parallel with the ball screw 40; a motor 42, which is connected to one end of the ball screw 40; a moving plate 43, whose inner nut is screwed with the ball screw 40, and the The lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com