Method for designing an automotive vehicle

A design method, automotive technology, applied in the automotive field, which can solve problems such as expensive and redundant design methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

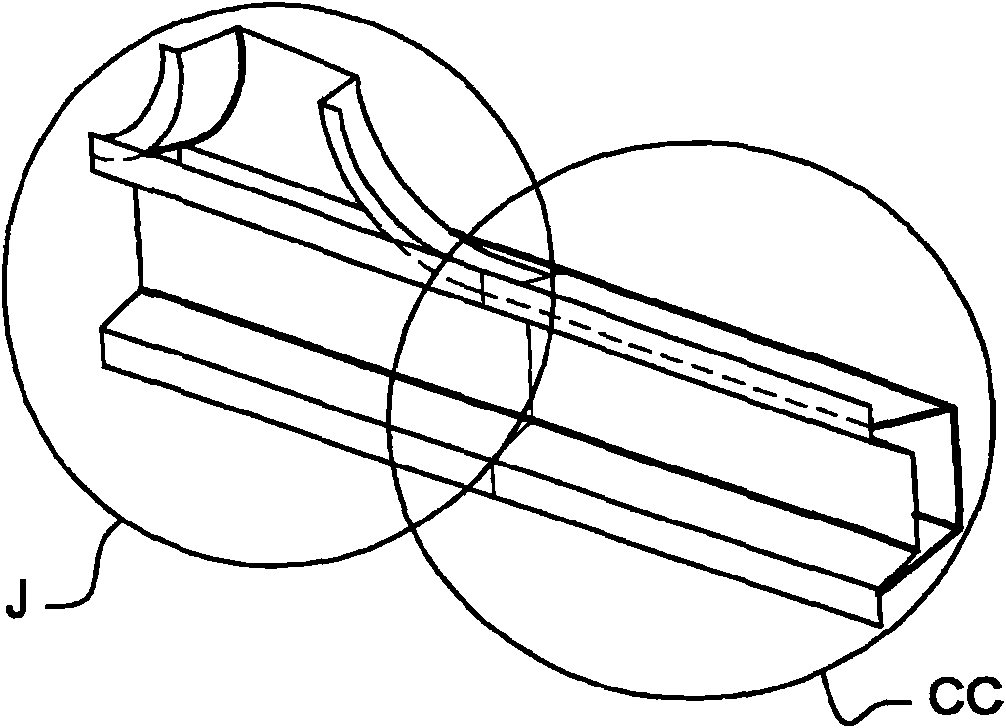

[0025] figure 1 An example of a test product is shown schematically in graphic form. The test product is functionally separated. It has a functional part J of the joint type and a functional part CC of the hollow body type. It can also have a board-like functional part. The test product is shown in geometric form, including parameter settings on the one hand and creation history on the other.

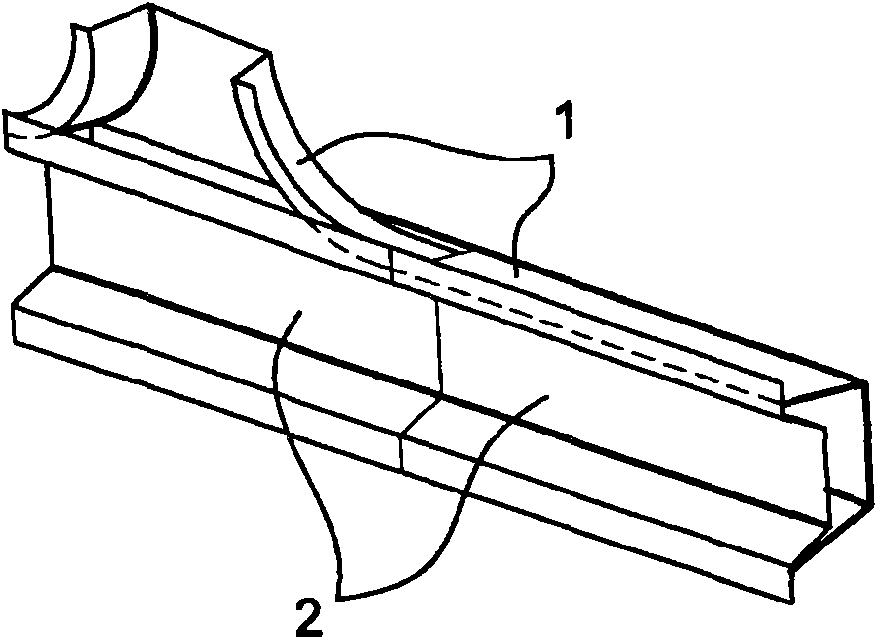

[0026] figure 2 An example of a work product is shown schematically in graphical form. The output product is divided into physical components. It has component 1 and component 2. The resultant product is incorporated into the test product, which also includes parameter settings but omits the full creation history. The outcome product is the unit that will be used in the course of the different stages that follow in the design method.

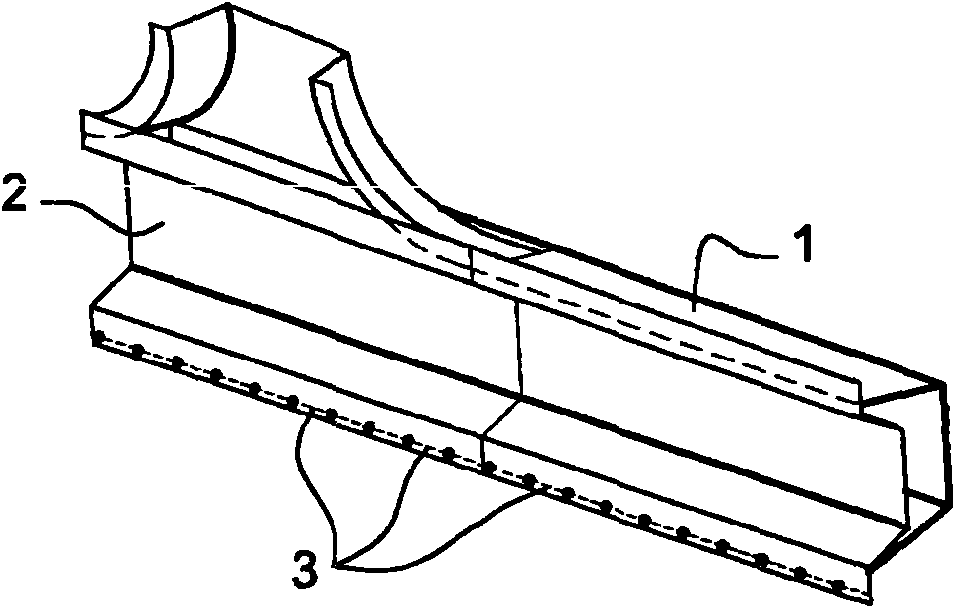

[0027] image 3An example of an assembly model is shown schematically in graphical form. The components 1 and 2 are connected together by a jo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap