Method for measuring thermal error of grinding wheel spindle of grinder

A measurement method and thermal error technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems that cannot be realized, and achieve the effect of solving thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0034] A method for measuring thermal error of a grinding wheel spindle of a grinding machine according to the present invention comprises the following steps:

[0035] (1) Non-contact displacement sensor setting

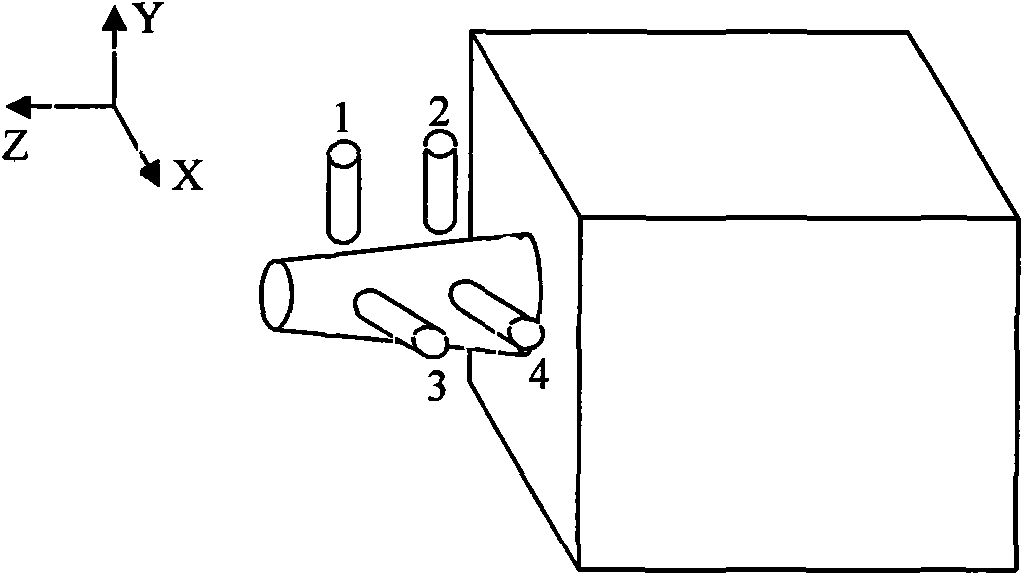

[0036] Such as figure 1 As shown, in order to measure the thermal deformation and inclination error in the two radial directions of the main shaft, two displacement sensors are respectively installed along the Z axis in the X and Y directions, wherein the first and third sensors 1 and 3 are located on the same plane, and the second , the fourth sensors 2, 4 are located on the same plane. For the measurement of the thermal deformation of the grinding wheel spindle, according to the evaluation method of the thermal effect of the ISO230-3 machine tool, it is required to read the measured value of the displacement sensor at least every 5 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com