Large light bar conveying device

A transport device and light rod technology, which is applied in glass transport equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of fragile and expensive light rods, and achieve the effect of being convenient for vertical, improving clamping efficiency and convenient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

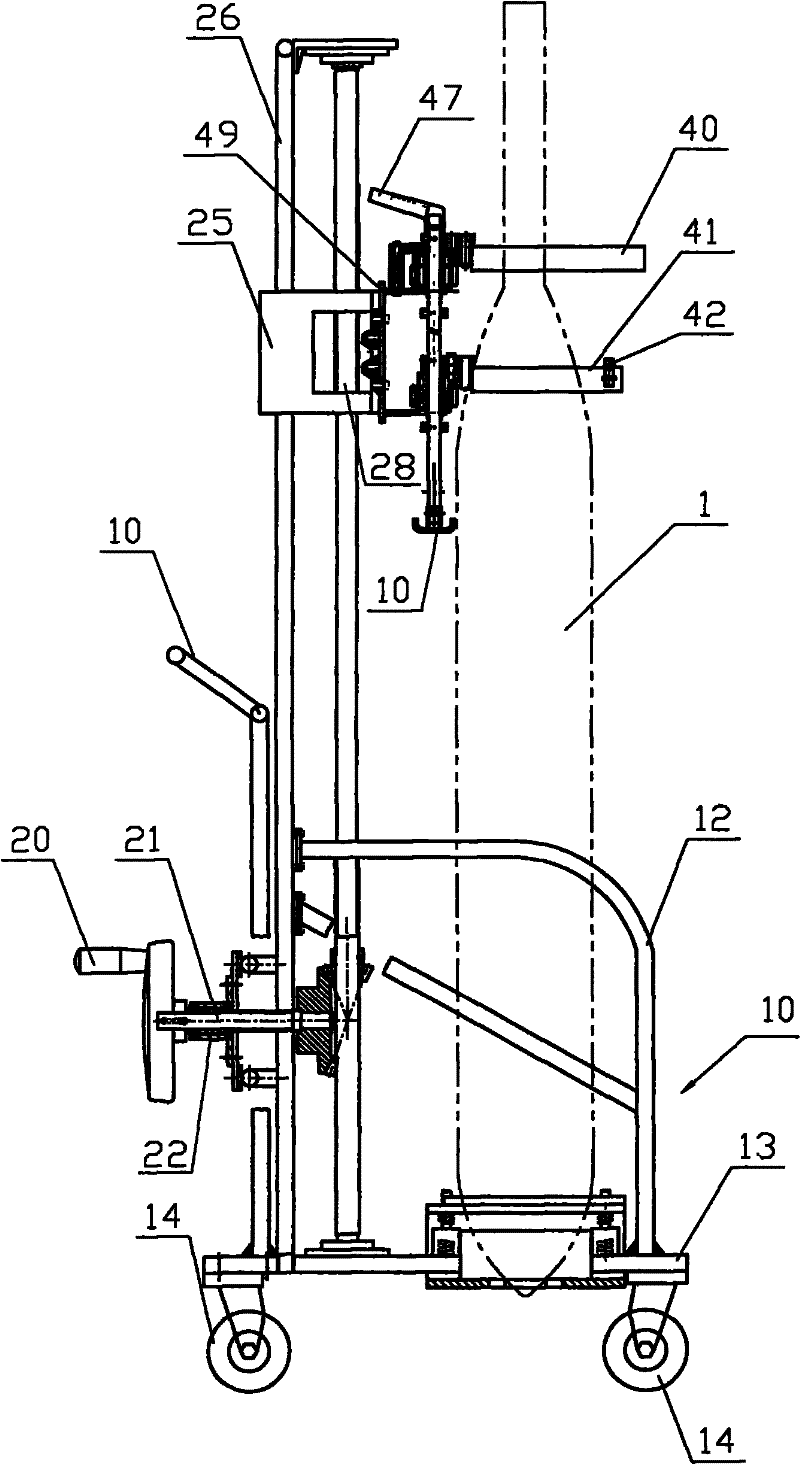

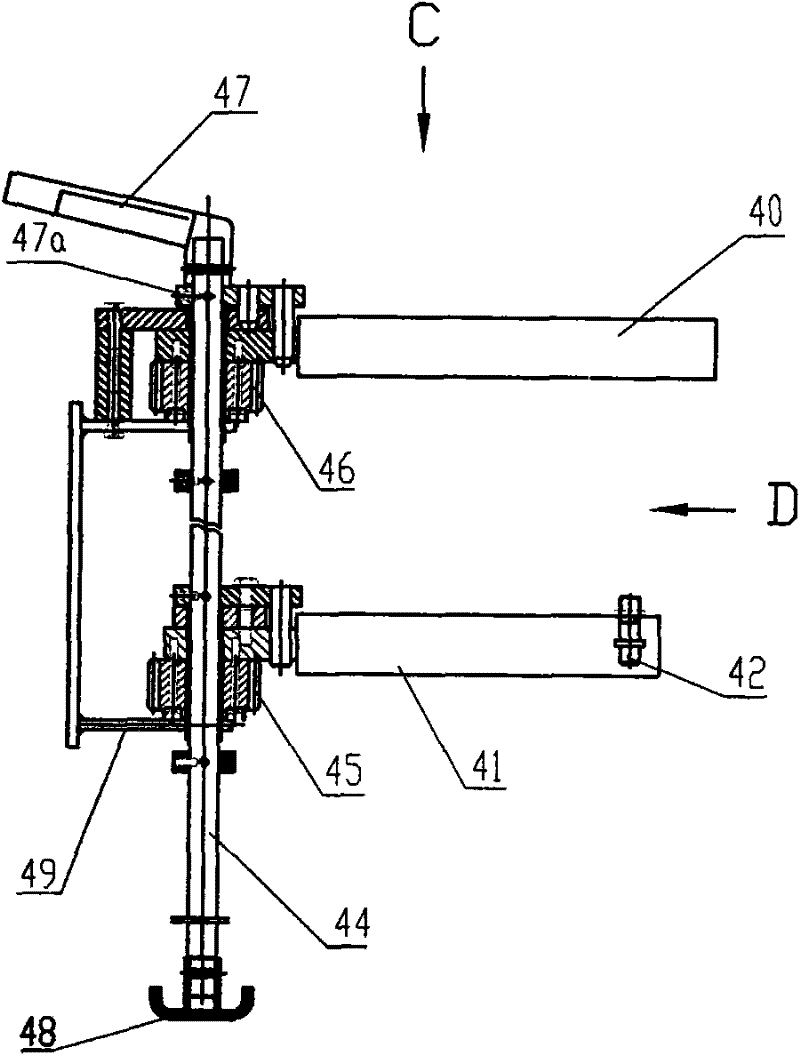

[0019] control figure 1 , The big light stick transportation device of the present invention mainly is made up of, transmission mechanism, clamping mechanism and supporting mechanism.

[0020] Cart 10 is made up of base plate 15 and handle 11 placed on base plate, guardrail 12 and four wheels 14 placed on base plate underside.

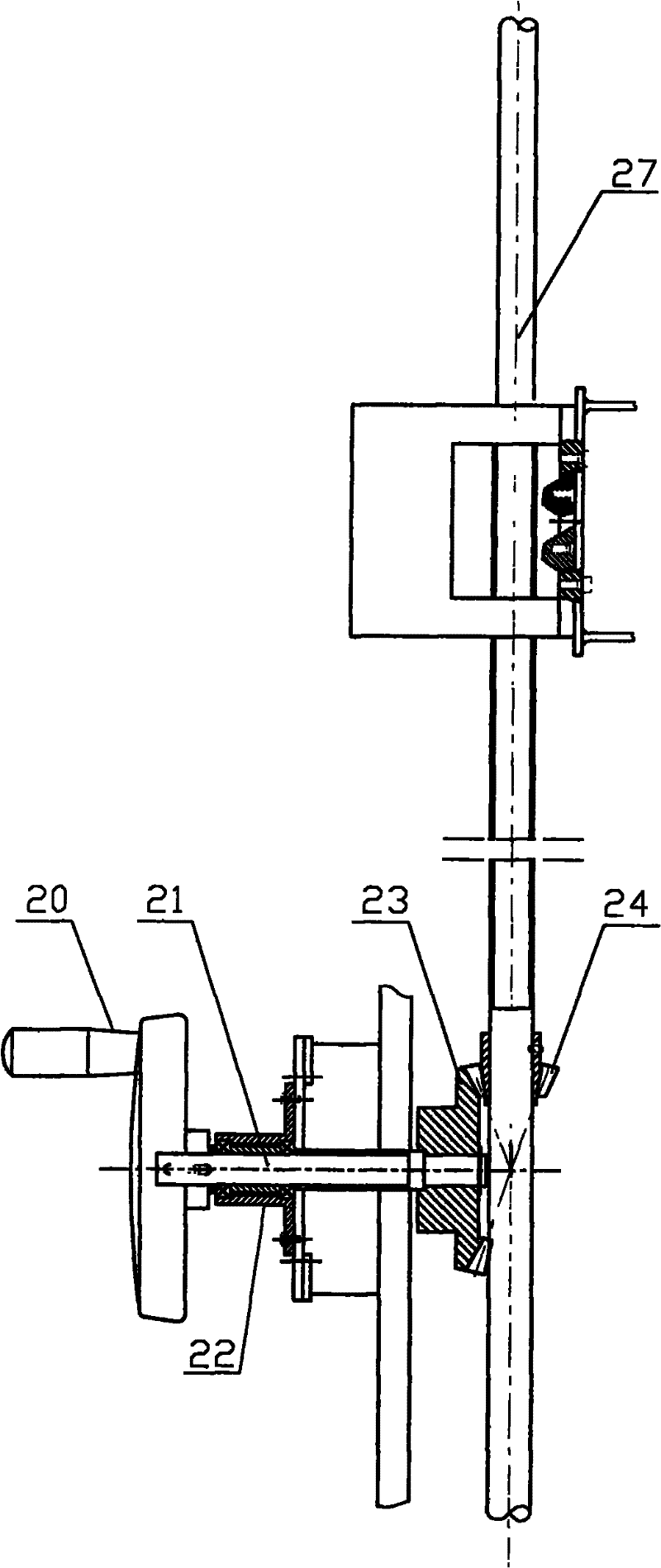

[0021] control figure 2 , Transmission mechanism is mainly made up of guide rod 26, screw mandrel 27, fixture 25, nut 28, crank 20, driving bevel gear 23, driven bevel gear 24, transmission shaft 21 and bearing seat 22. Guide rod 26, screw mandrel 27 are vertically installed on the base plate 13 of cart. The nut 28 is fixed on the clamp 25, and the clamp 25 is also provided with a guide hole (or groove) parallel to the corresponding screw hole of the nut. The clamp 25 is screwed with the screw mandrel 27 by the nut 28, and slides with the guide rod 26 through the guide hole. connect. The bottom of screw mandrel 27 connects driven bevel gear 24, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com