Liquid heating ware overheating protection controller assembly

An overheating protection and controller technology, which is applied to fluid heaters, water heaters, cooking utensils, etc., can solve the problems of overheating damage to the heating utensils, affecting the normal use of the heater, and burning out the heating utensils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

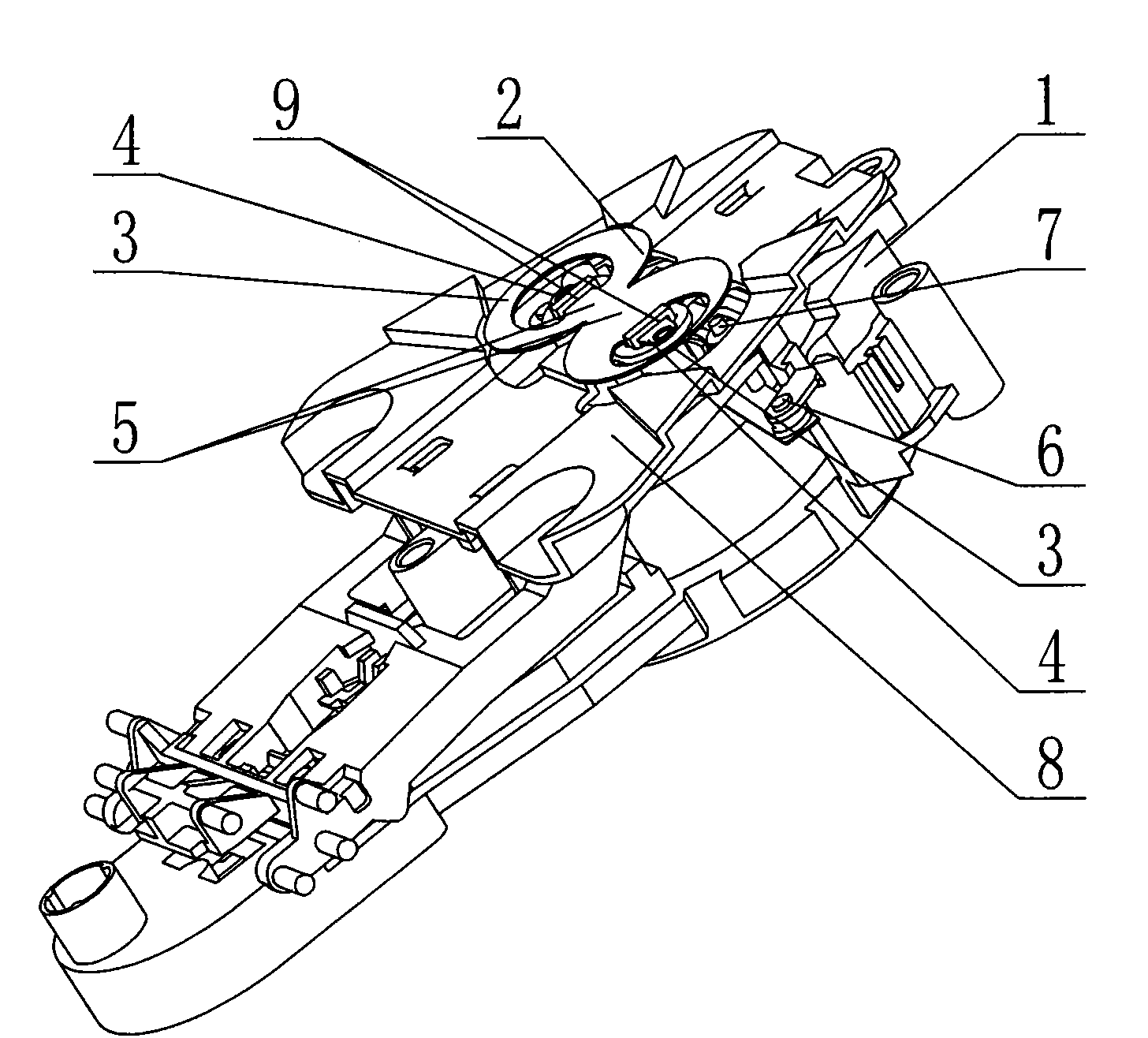

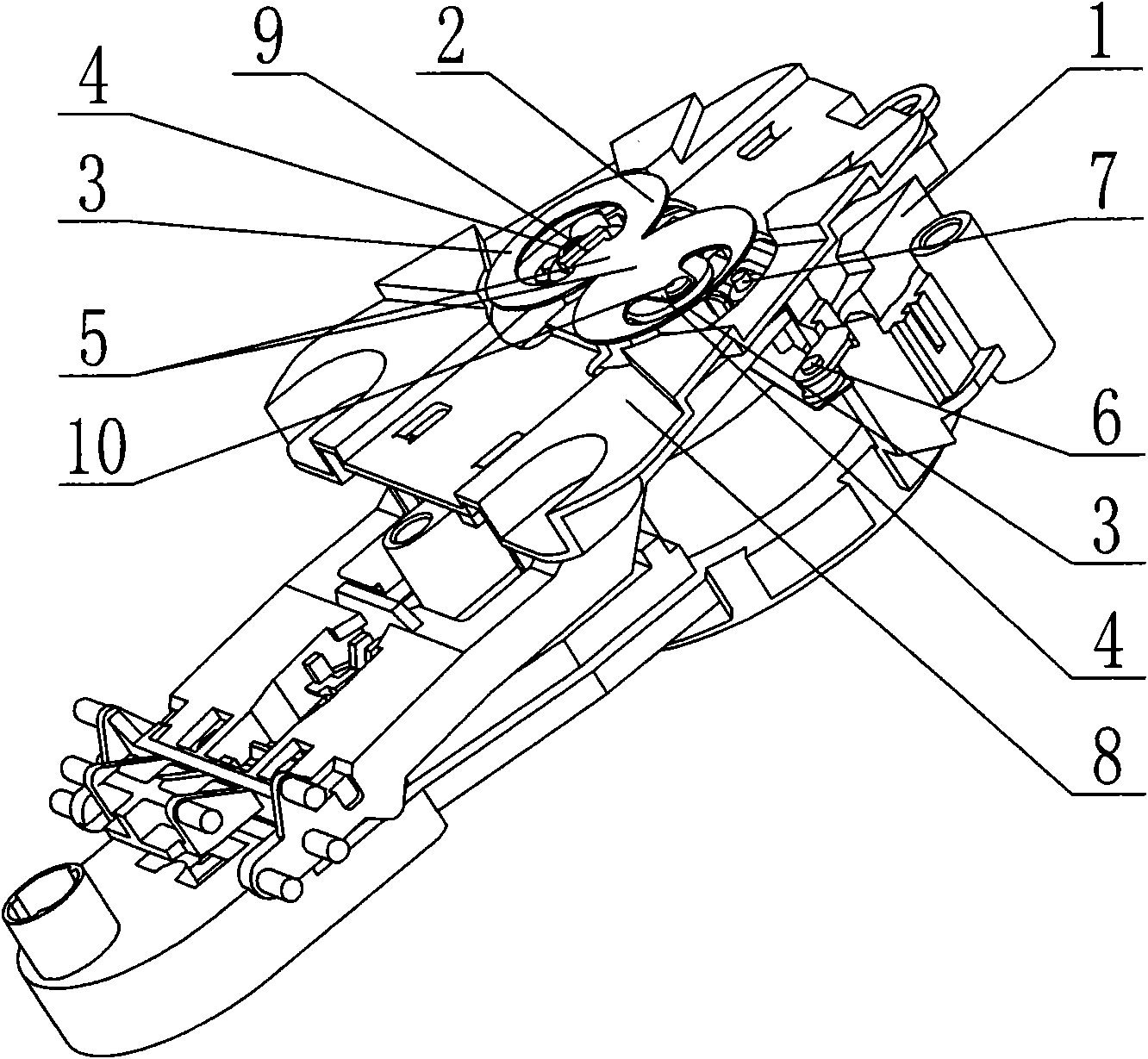

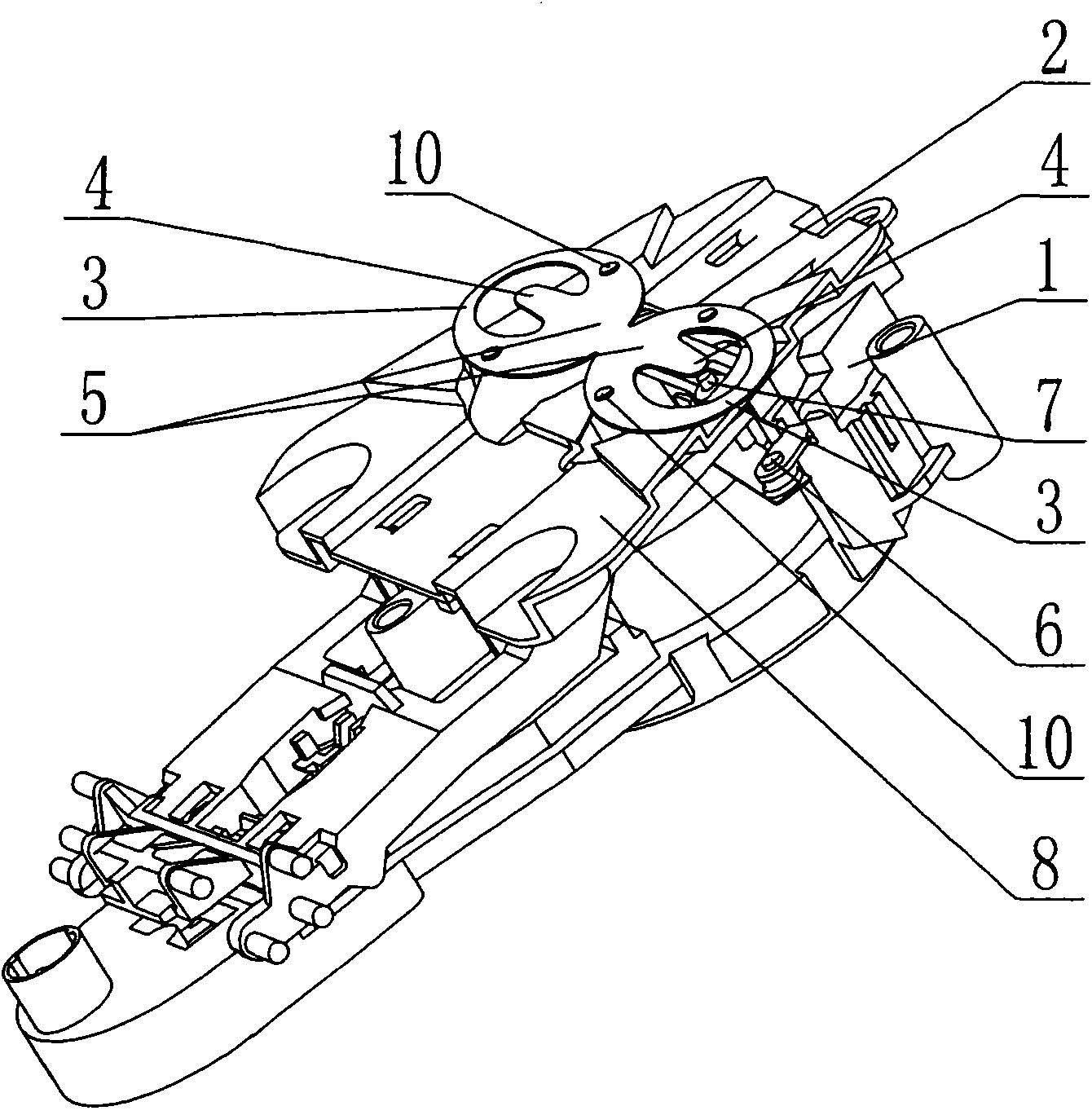

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0015] Among them: 1. Controller body; 2. Single-chip dual-actuation thermal bimetallic actuator; 3. Outer sudden jump wing; 4. Inner tongue; 5. Tongue root; 6. Switch contact; 7. Push rod ; 8. Fixed plate; 9. Inner tongue jack; 10. Rivet; 11. Edge line of actuating unit; 12. Common joint; 13. Mounting hole;

[0016] like figure 1 , figure 2 As shown, the liquid heating vessel overheating protection controller assembly includes a controller body 1; the upper surface of the controller body 1 is provided with a monolithic dual-actuation thermal bimetal actuator 2, and the monolithic dual-actuation The dynamic heat-sensitive bimetallic actuator 2 is formed on a piece of bimetallic sheet to form two conjoined and relatively independent actuating units. The outer jumping wing 3 and the tongue root 5 of the inner tongue 4, the tongue base 5 of the two actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com