A Low Power Consumption Cooling Chip System

A cooling chip and low power consumption technology, which is applied in the field of low power consumption cooling chip system, can solve the problems of easy damage and high energy consumption of the cooling chip, and achieve the effect of reliable overheating protection and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

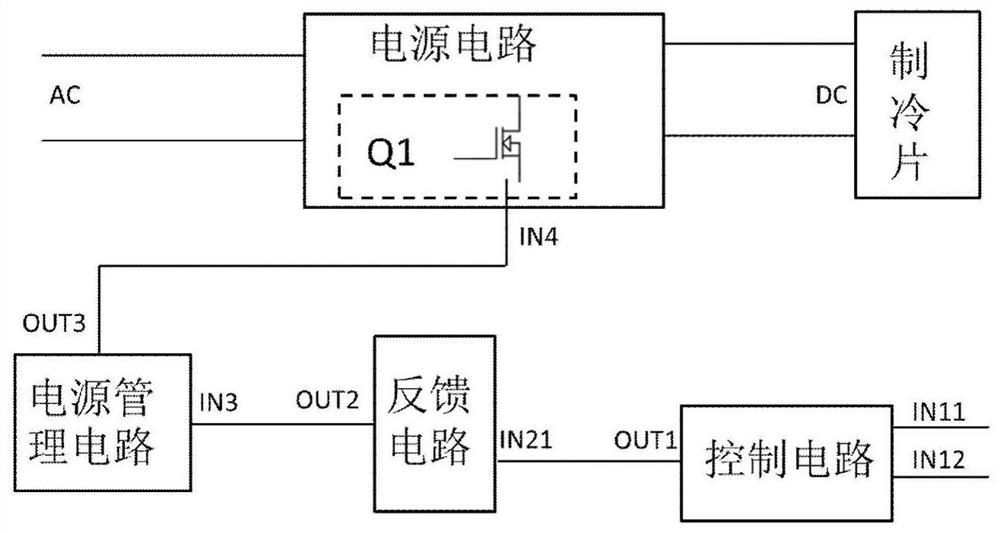

[0037] Please refer to the attached figure 1 , a refrigerating sheet system, comprising a power supply circuit, a refrigerating sheet, a switching power supply controller, a feedback circuit and a control circuit. The input end of the main circuit of the power supply circuit is connected to the mains, and the output end outputs the adjusted direct current to supply power for the cooling plate. The power supply circuit also includes a part having a switch tube Q1. For example, a switch tube Q1 and a transformer can be used to form a switch power supply. The control terminal of Q1 is the control terminal of the power supply circuit.

[0038] The control circuit essentially has two inputs IN11 and IN12. The first input terminal IN11 is connected to a reference voltage, and the reference voltage is related to the ideal temperature of the cooling device where the cooling plate is located. The second input terminal IN12 provides a detection voltage, which is related to the actua...

Embodiment 2

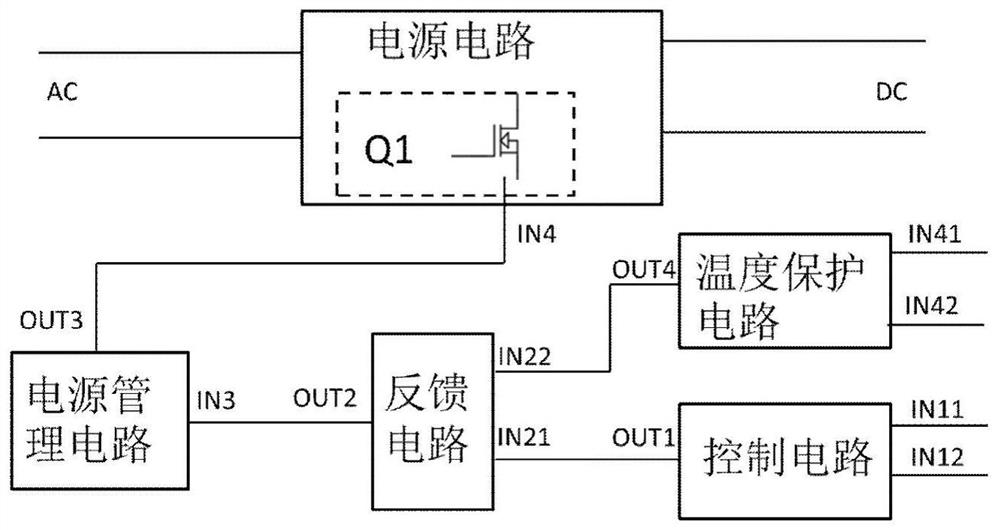

[0044] refer to figure 2 , the cooling chip is sensitive to overheating faults, and the cooling chip may be damaged quickly after a certain temperature is exceeded. Therefore, in this embodiment, a temperature protection circuit is added. It has input terminals IN41 and IN42, and an output terminal OUT4. The input terminal IN41 is connected to a reference voltage signal, and the reference voltage signal is related to the limit temperature of the refrigerating plate. The input terminal IN42 is connected with a detection voltage signal, and the detection voltage is related to the actual temperature of the refrigerating sheet. When the temperature protection circuit detects that the temperature is too high, it will output an over-temperature protection signal to the feedback circuit at the output terminal OUT4.

[0045] The feedback circuit has a second input terminal IN22, which receives the over-temperature protection signal output from the output terminal OUT4. And enable...

Embodiment 3

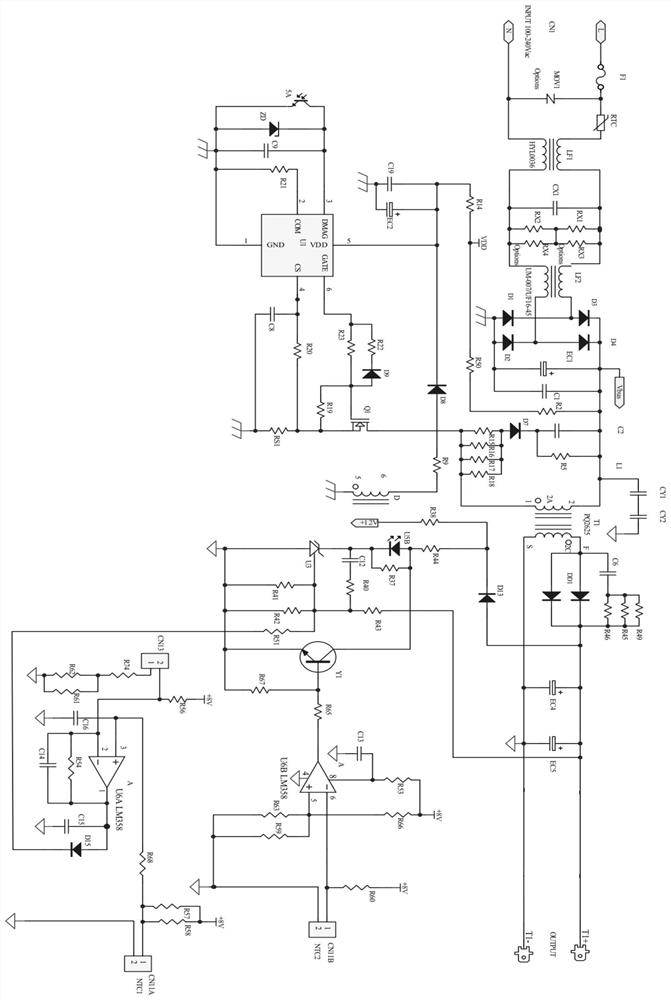

[0047] refer to image 3 , gives the specific composition of each specific circuit module. The input terminal of the power supply circuit receives the commercial power, passes through the filter unit, and then reaches the transformer unit. The primary winding of the transformer unit is connected with a switch tube Q1, and the secondary winding of the transformer outputs direct current to supply power for the cooling plate.

[0048] The main components of the control circuit are the PI regulator composed of the operational amplifier U6A and its peripheral circuits. image 3 LM358 is selected as the operational amplifier in the circuit, of course, other types of operational amplifier units can also be selected. The non-inverting input terminal of the operational amplifier U6A is IN12, and the inverting input terminal is the input terminal IN11. The non-inverting input terminal of the operational amplifier U6A is connected to a detection voltage, and the detection voltage is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com