Laser dynamic balance adjustment method and device thereof

An adjustment method and an adjustment device technology, which are applied in static/dynamic balance testing, measuring devices, laser welding equipment, etc., can solve the problem that it is difficult to rotate the rotating body and the prism synchronously, and cannot process materials with high precision. Rotating body dynamic balance and other issues, to achieve the effect of small processing deformation, high production efficiency and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

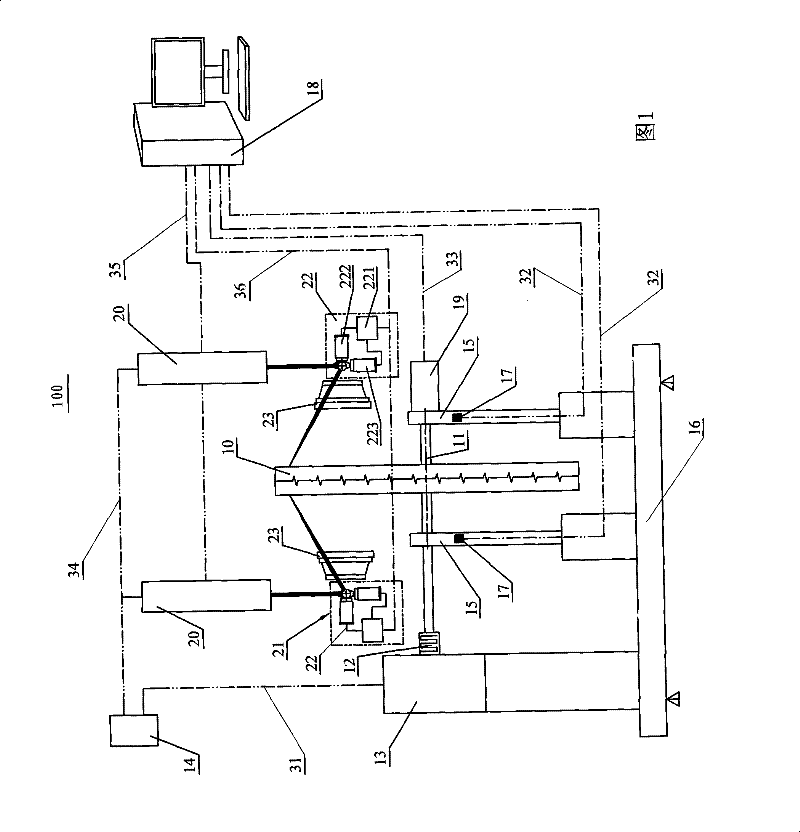

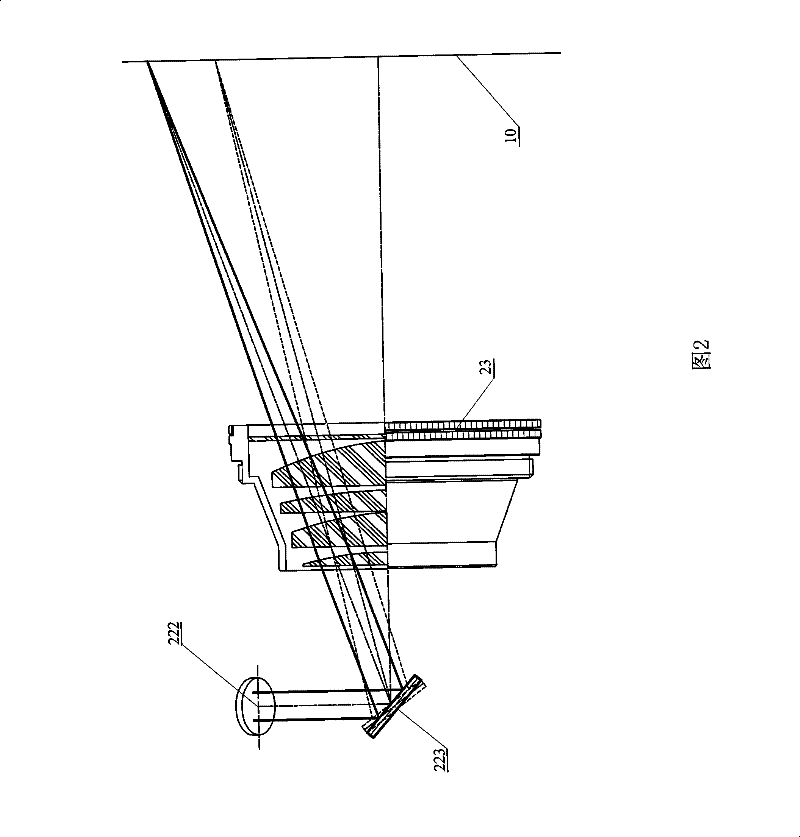

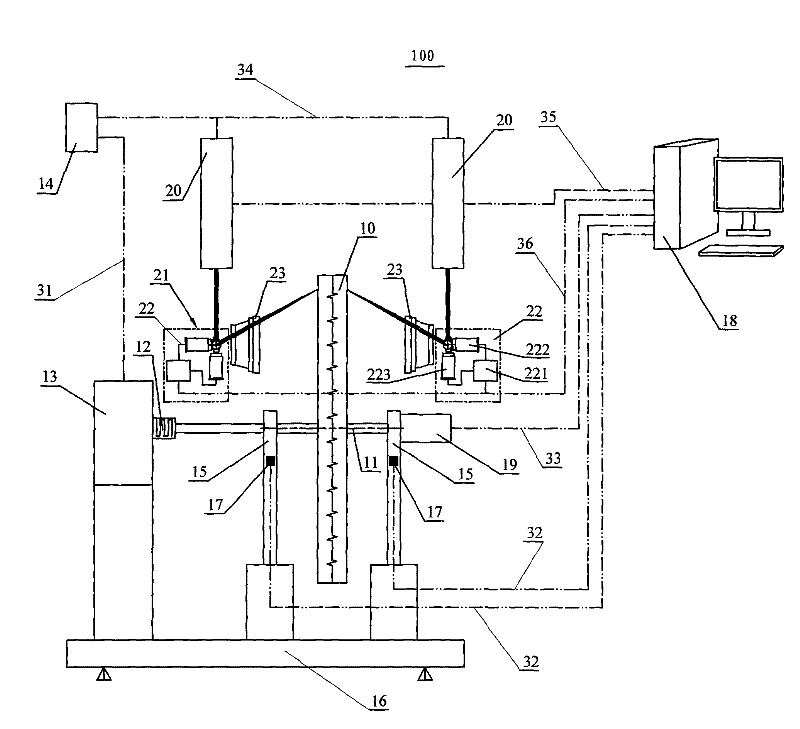

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] see figure 1 with figure 2 It is a structural schematic diagram of the first embodiment of the laser dynamic balance adjustment device of the present invention. The laser dynamic balance adjustment device 100 of the present invention is a kind of laser non-contact processing performance to adjust the dynamic balance of the workpiece 10. The workpiece 10 is a rotating body. Shaft workpieces, disc workpieces, crankshaft workpieces and other rotary workpieces, such as motor rotors, centrifugal fan blades, wind wheels, flywheels, pulleys, brake drums, horizontal CNC machine tools, CNC machine tools, eccentric wheels, etc., these The mass distribution of the workpiece 10 of the rotary part makes the centrifugal force system reach a balance when the rotary part works, so as to eliminate the additional dynamic pressure and reduce the harmful ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com