Device for shaping goods that have been produced from a strand of material

A material strip and article technology, applied in the field of candy-style dessert forming devices, can solve the problems of less closing time for cutting edges and no time for materials, and achieve the effects of avoiding damage to candies, increasing sealing time, and long contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

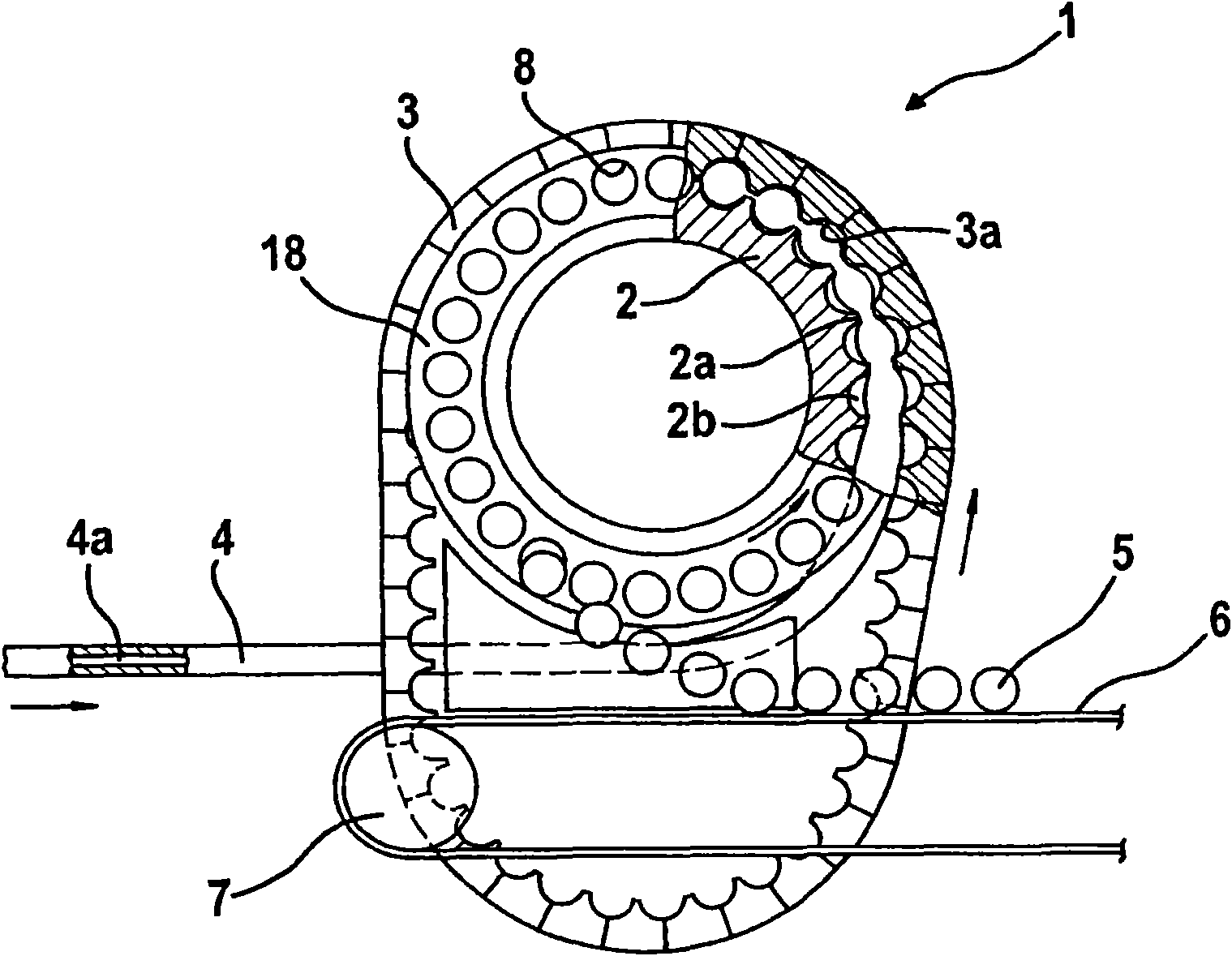

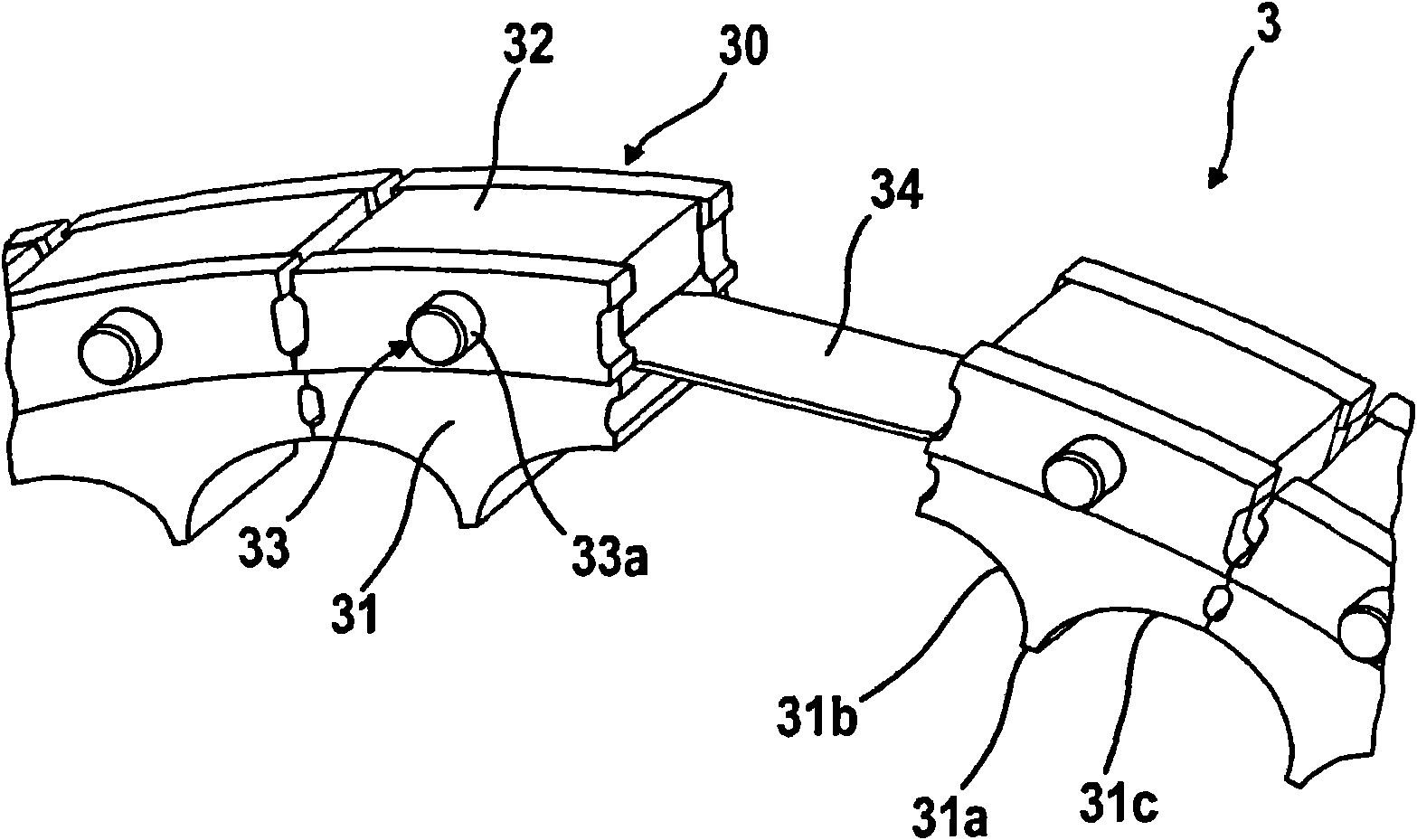

[0020] Below with the help of Figures 1 to 5 A device 1 for shaping objects, in particular confectionery, made of strips of material is described.

[0021] These figures show a device 1 for dividing and pressing confectionery 5 from a rolled and drawn material strip 4 , in particular filled with a liquid or semi-liquid filling 4 a. Note, however, that instead of candy any other form of dessert or chewing gum or the like can be made.

[0022] especially if figure 1 As shown, the device 1 comprises an inner split ring 2 and an outer split ring 3 . The outer dividing ring 3 is here a flexible ring, which in this exemplary embodiment is provided as a chain element.

[0023] The device 1 also includes a conveyor belt 6 which is diverted at turning rollers 7 and leads out of the finished shaped candies 5 (see figure 1 ).

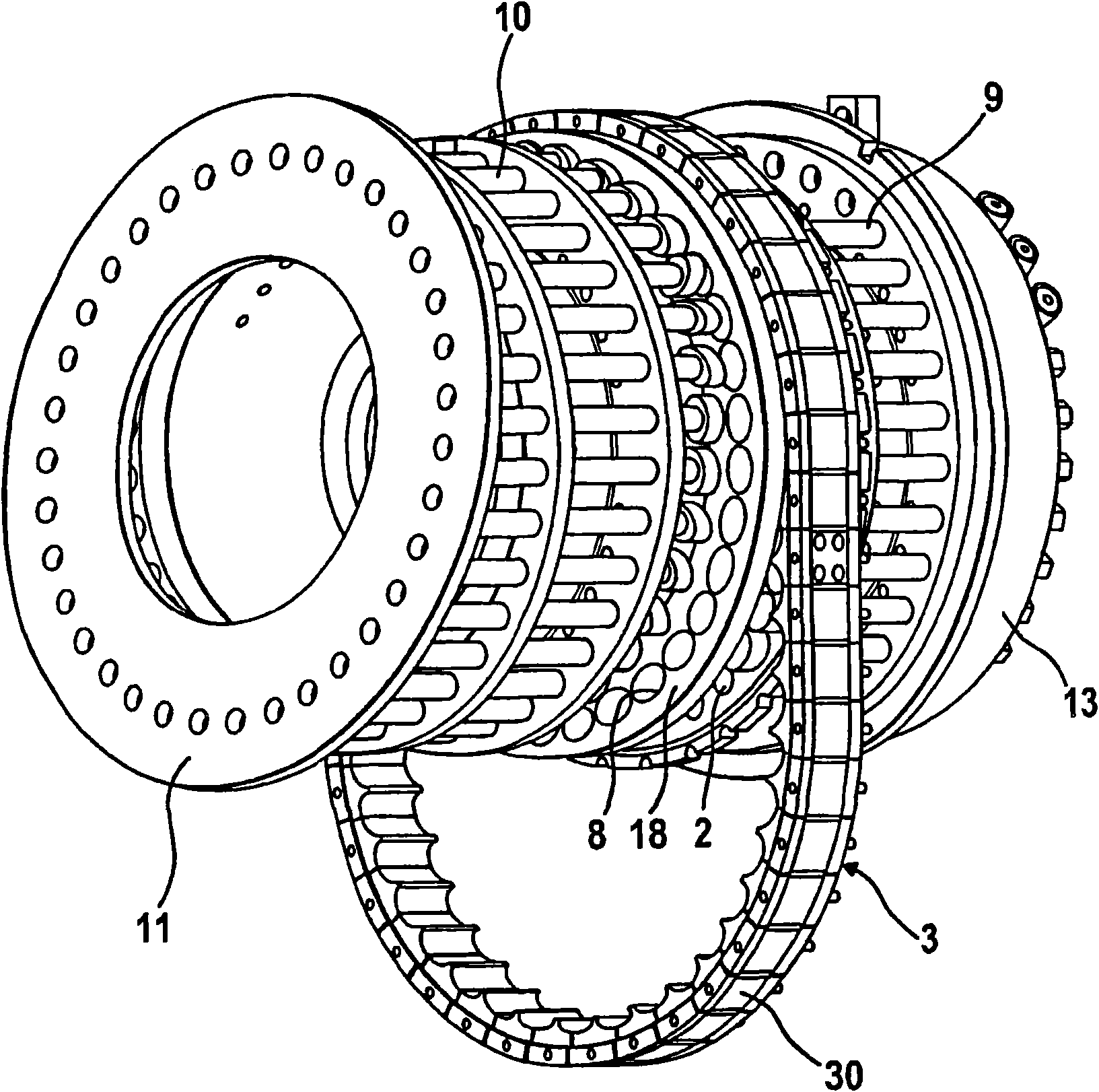

[0024] Such as figure 2 As shown, the device 1 comprises a plurality of first pressing punches 9 and a plurality of second pressing punches 10 . The firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com