Method for processing forward gear shifting block of automobile parts

A technology of auto parts and processing methods, which is applied in the processing field of forward gear shifting blocks of auto parts, and can solve the problems of unguaranteed parallelism, symmetry, position and product hardness, short service life, and poor product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

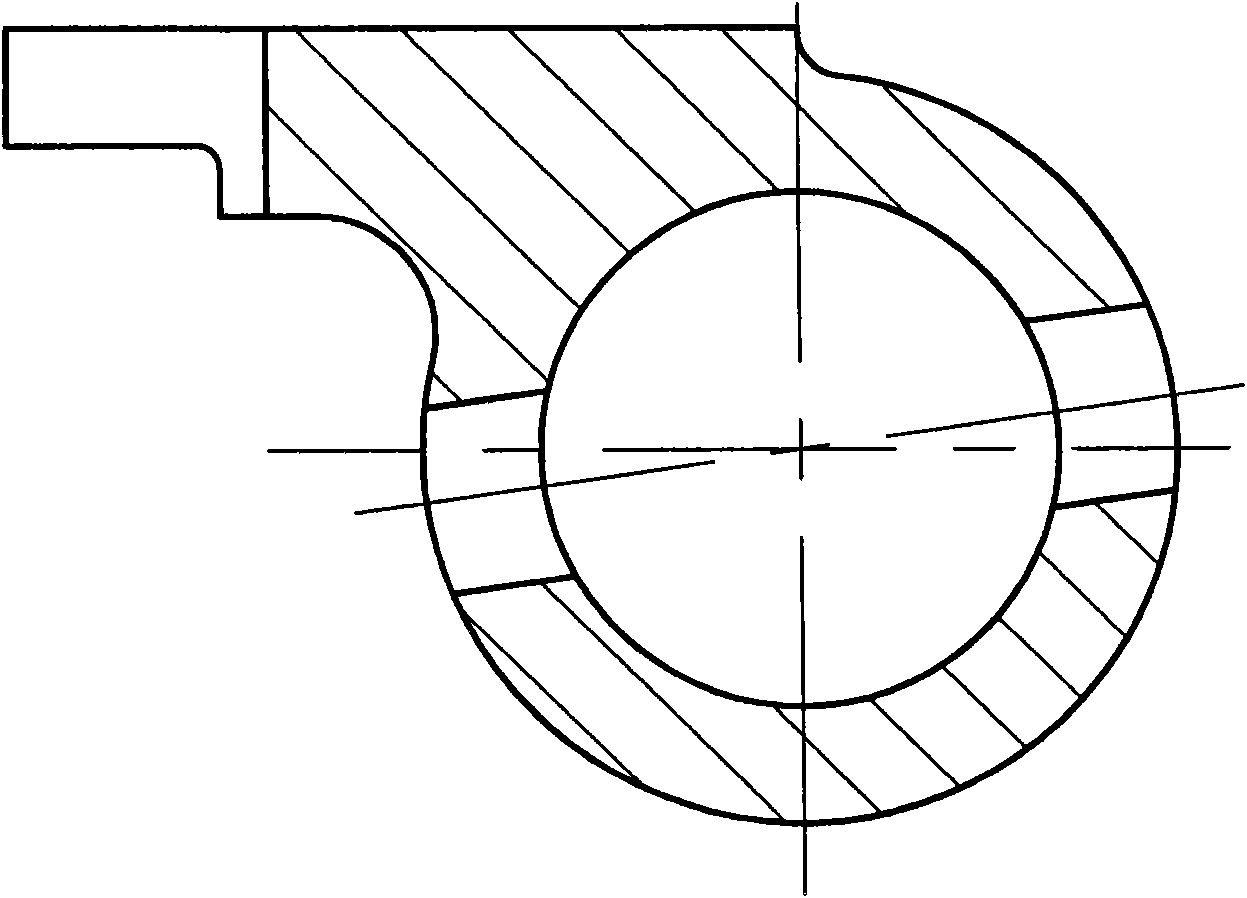

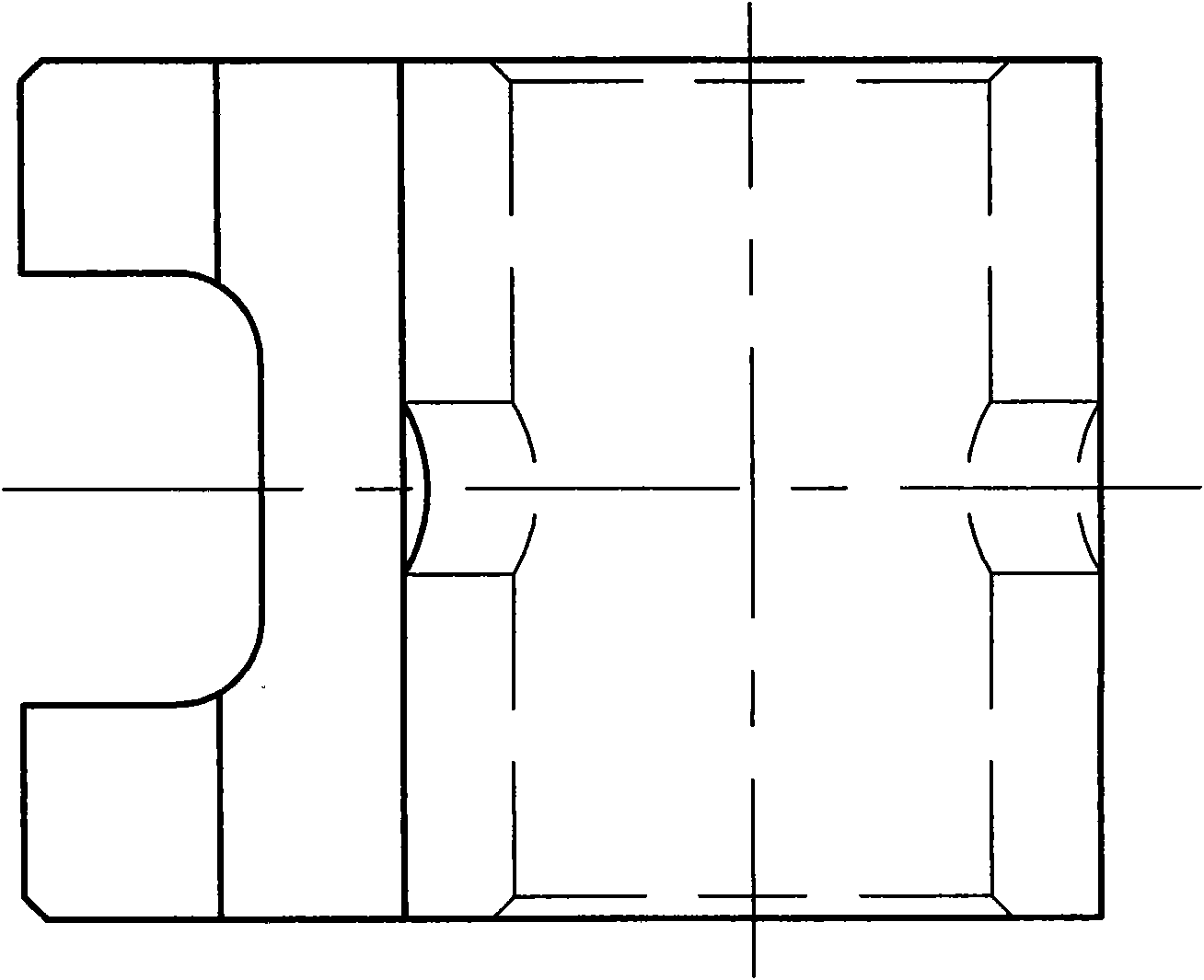

[0006] Below in conjunction with accompanying drawing, the present invention is further described;

[0007] In the figure, the processing method of the forward shift block of the auto parts is characterized by: turning: put on the lathe and clamp it, drill the through hole, ensure that the thickness deviation of the hole arm does not exceed 0.5, turn the end face, and the allowance is evenly distributed; bore the through hole , leaving honing allowance and chamfering; car: raise the core fixture and clamp it, and leave the grinding allowance on the other end of the car to ensure that the parallelism is 0.15 and chamfer; flat grinding: take the end face of the first car as the reference and suck it tightly , Grind the end face to the size shown in the figure to ensure that the parallelism is 0.05; milling: upper milling clamp, based on the processed inner hole, press it tightly, mill the large plane perpendicular to the center of the hole to the center as the size shown in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com