Interference jet printing method in variable dot printing of inkjet printer

An inkjet printer and dot printing technology, which is applied in the field of interference inkjet printing, can solve the problem of high positioning requirements, achieve the effect of reducing the generation of reflective stripes and sufficient ink volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Please refer to the accompanying drawings for a further description of the present invention.

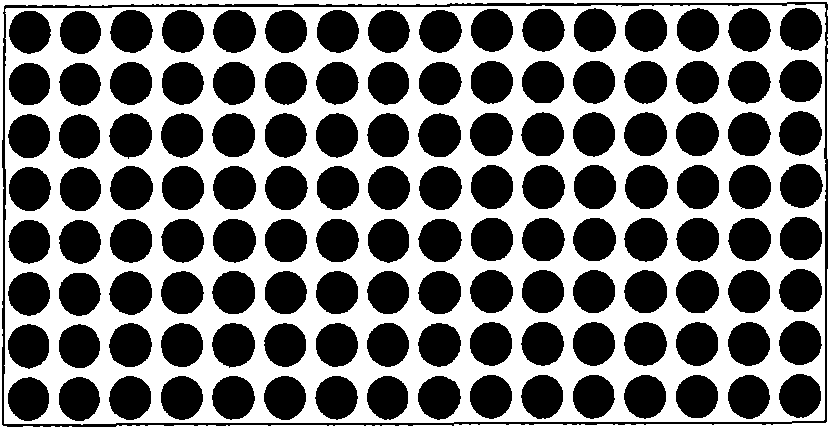

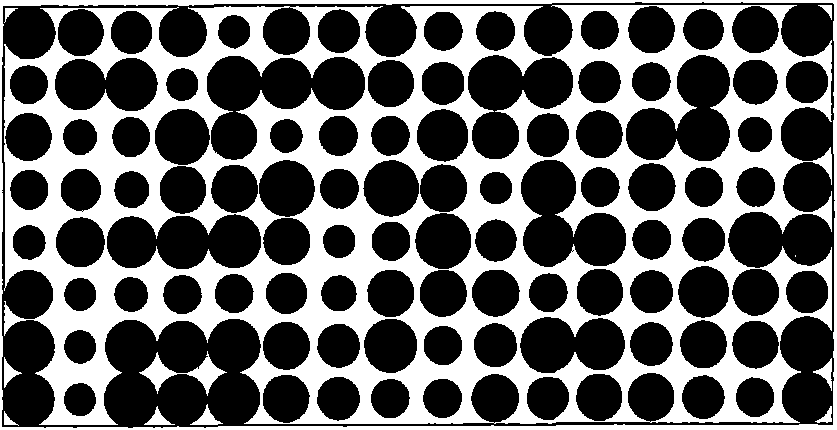

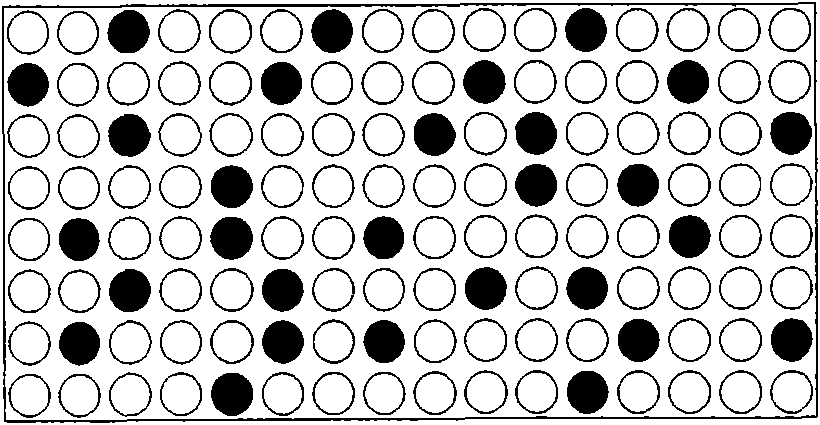

[0020] Such as Figure 1b with Figure 2b As shown, the present invention provides a kind of interference inkjet printing method in the variable point printing of inkjet printer, the variable point nozzle of inkjet printer, when printing with uniform dots, add interference spray dots, that is, change the size of the dots at the original average dot distribution position, Make the average total value of the spray points after the change consistent with the average total value before the change point, and keep the color density consistent, that is: the total amount of ink dots in the average distribution per unit area is A=m*m*Dn 2 , where: m is the number of points on a certain side in a unit area; Dn is the size and diameter of a certain n points.

[0021] Taking seven kinds of diameter changes as an example, the total amount of ink dots that interfere with the distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com