Groove joint type buckling restrained brace device

A technique for buckling bundle bracing and supporting parts, which is applied in the field of buckling bundle bracing devices, which can solve the problems of easy occurrence of buckling, high difficulty, and increased fixing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

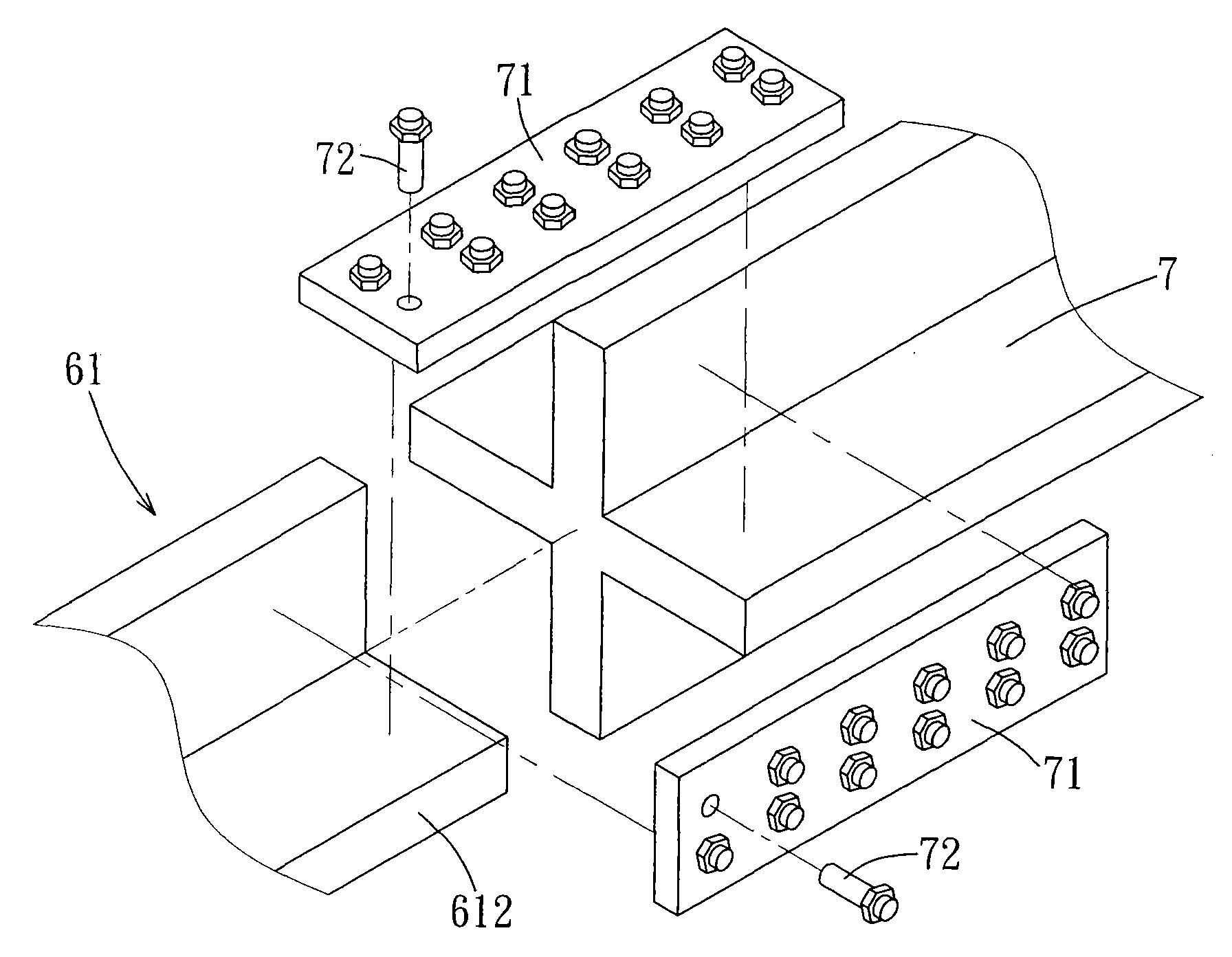

[0058] refer to Figure 10 , Figure 11 and Figure 12 In the first preferred embodiment of the present invention, the groove-joint buckle restraint system support device 100 is fixed between two joint plates 210 of a building steel frame 200, and includes a first axial force member 1 and a restraint unit 2 .

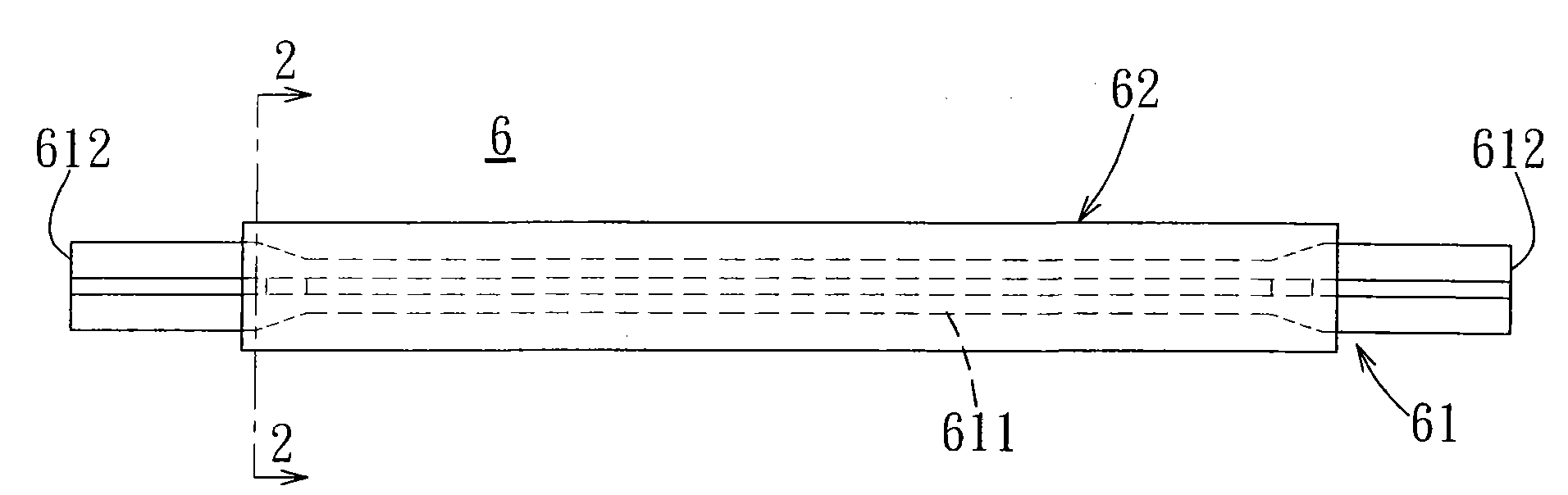

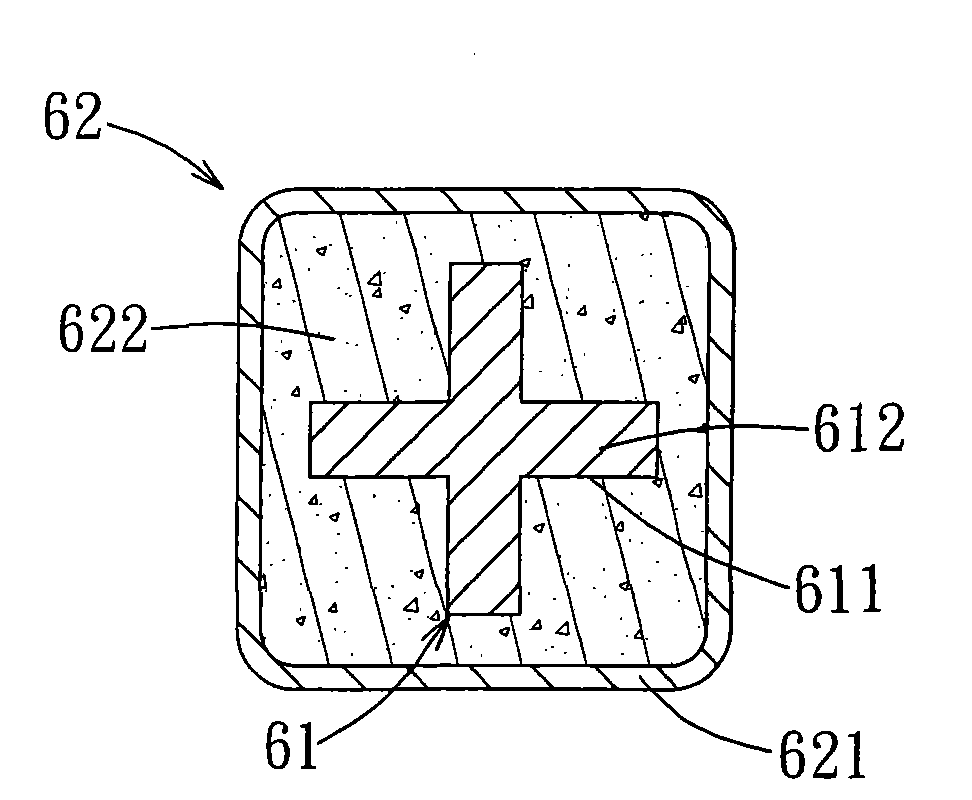

[0059] The first axial force member 1 includes a central section 11 and two connecting sections 12 extending integrally from both ends of the central section 11. The central section 11 has a long plate-shaped main body 111, and each connecting section 12 has a The long plate-shaped main body 111 has a parallel first support portion 121 and a first contact portion 122 protruding from the first support portion 121 . In this embodiment, the first supporting part 121 defines a first groove 123 for inserting the connecting plate 210 in the axial direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com