Movable optical fiber connector with improved structure

An optical fiber connector and activity technology, applied in the field of optical connection devices, can solve the problems of unreliable fixation and difficult fixation of optical cables, and achieve the effects of speeding up docking, easy maintenance and replacement, and reliable fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]

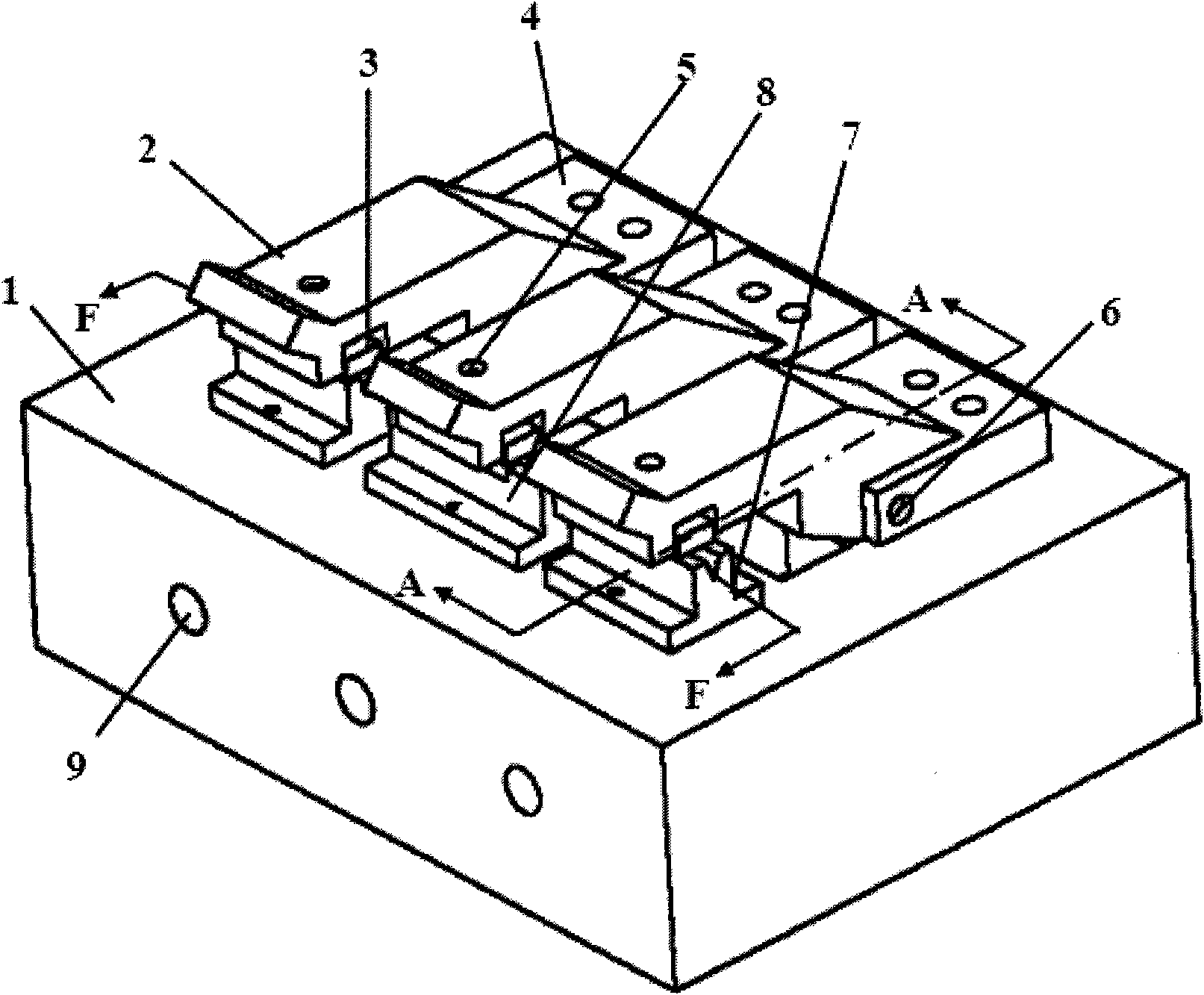

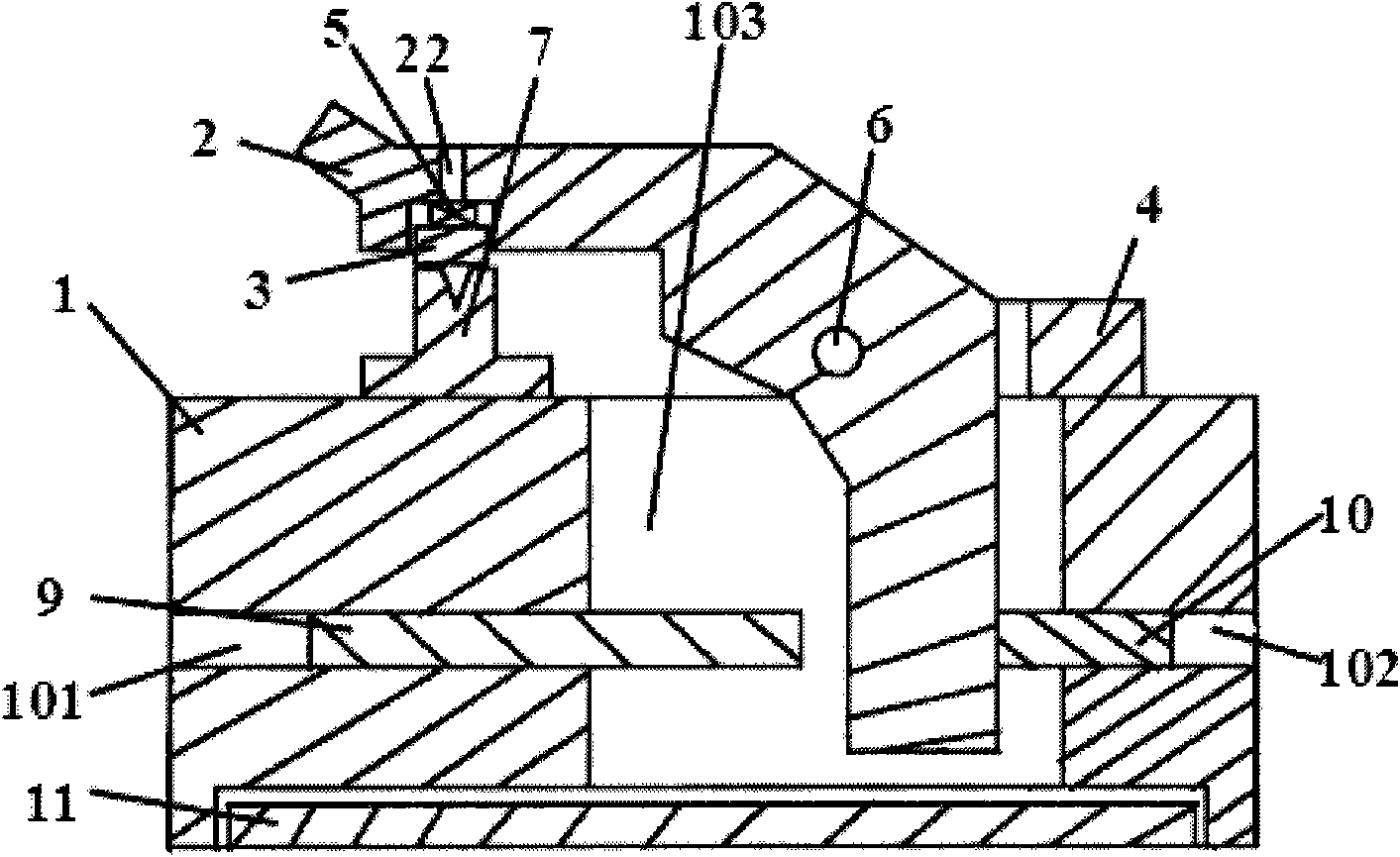

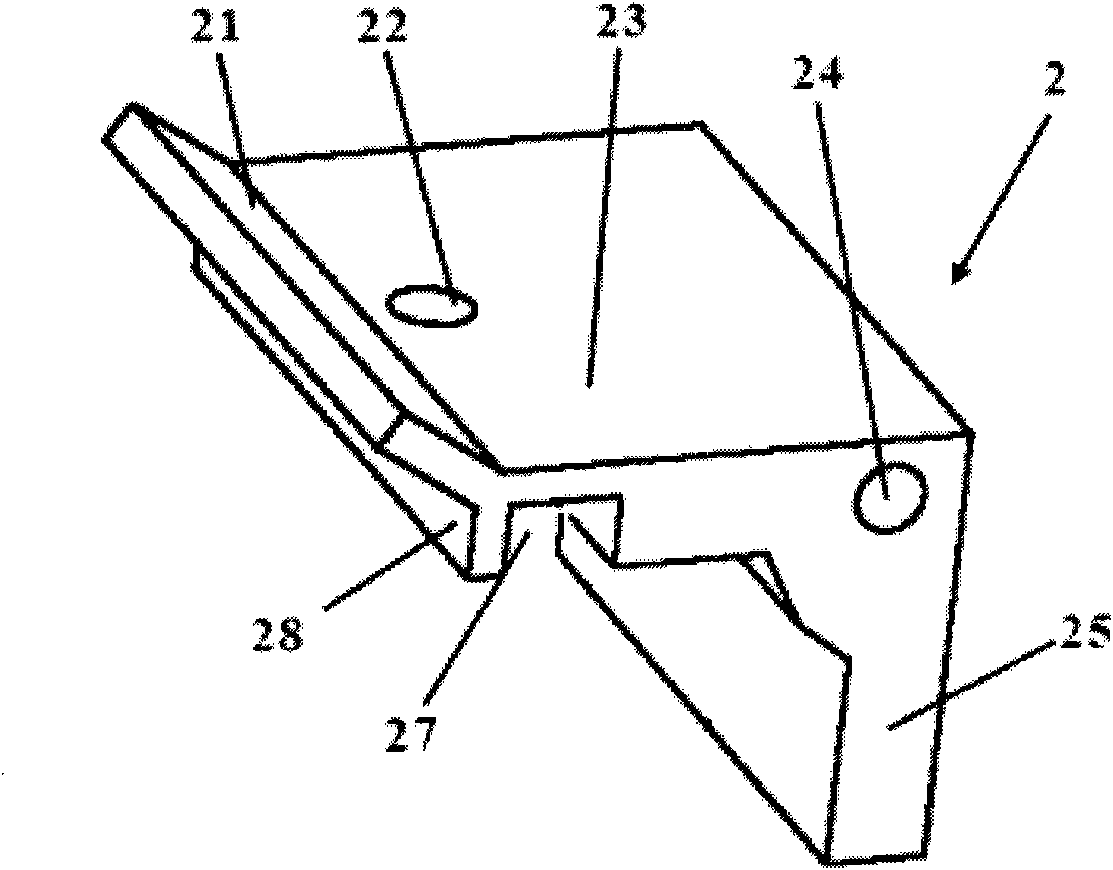

[0021] Such as figure 1 and figure 2 As shown, the optical fiber connector with improved structure disclosed by the present invention includes: a base 1, the upper bottom surface of the base 1 near the front end is fixed with a V-shaped groove 7 on the left and a right and a V-shaped groove 8 in the middle, and the three V-shaped grooves 8 The groove is used to accommodate the reference optical fiber and the optical fiber to be tested; three concave plates 4 are fixed on the bottom surface of the base 1 near the rear end surface, the concave surface of the concave plate 4 faces the front end of the base 1, and the rear end of the pressure plate 2 is inserted In the recess of the board 4, three shafts 6 passing through the right side of the concave board 4 connect the three concave boards 4 with the three pressure plates 2 respectively. 2. The fiber tightness adjustment spring 5 located in the groove of the pressure plate 2 and the pressure block 3 located below t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com