Method for producing light-emitting device

A technology for a light-emitting device and a manufacturing method, which is applied to the lighting device, the parts of the lighting device, and the cooling/heating device of the lighting device, etc. problem, to achieve the effect of suppressing color deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0044] (light emitting device)

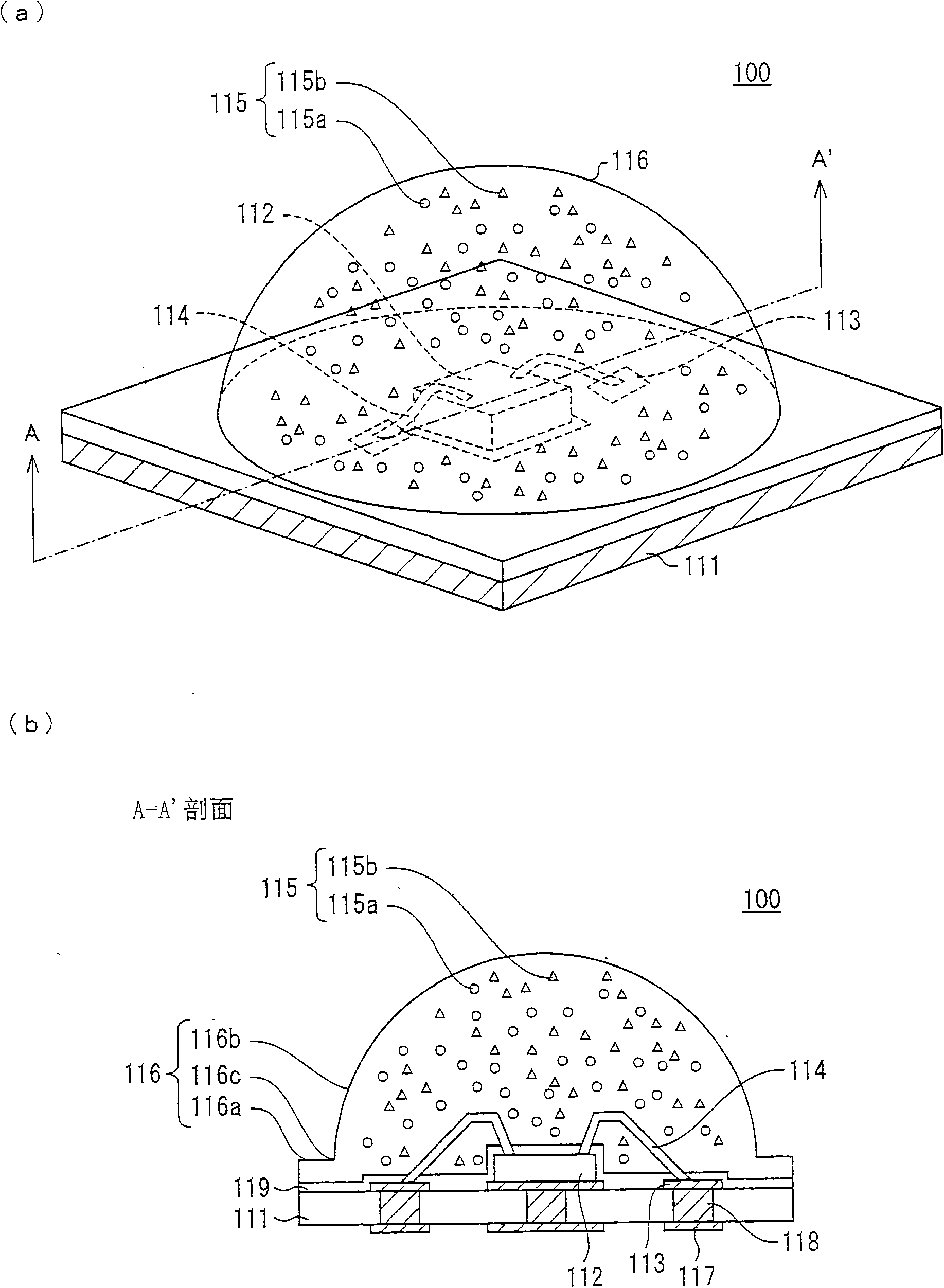

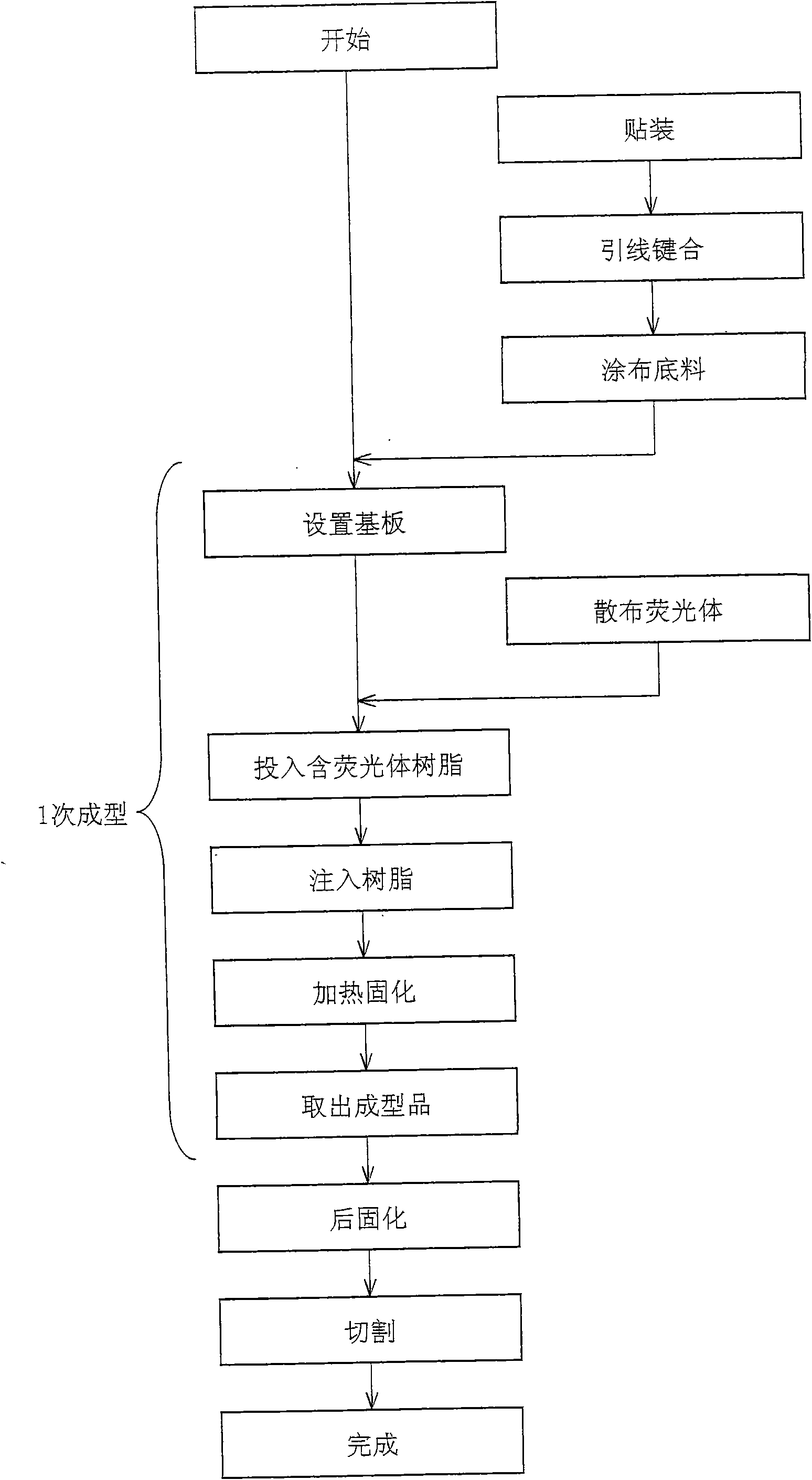

[0045] figure 1 It is an external view of the light emitting device according to the first embodiment of the present invention. The light emitting device 100 has a substrate 111 , a chip 112 mounted on the substrate 111 , leads 114 for connecting the chip 112 and wiring 113 , and a sealing resin 116 . The substrate 111 is, for example, a square with a length and width of 3.2 mm and a thickness of 0.6 mm; the sealing resin 116 covers the chip 112 , wiring 113 , leads 114 and the substrate 111 . The sealing resin 116 is used as a wavelength conversion part, and the fluorescent substance 115 is previously dispersed in the inside.

[0046] In the following description, the wavelength converting portion or the phosphor-containing resin, peripheral layer, and transparent resin described later will be appropriately rephrased as sealing resin.

[0047] The sealing resin 116 has a flat portion 116 a arranged to overlap the substrate and a hemispheric...

Embodiment approach 2

[0093] Figure 6 It is an external view of a light emitting device according to a second embodiment of the present invention. In this embodiment, a light-emitting device is manufactured by the same method as in the first embodiment, the wavelength conversion portion 216 of the light-emitting device is covered with a transparent peripheral layer 121, and the peripheral layer 121 is formed by secondary molding of a transparent resin.

[0094] In the following description, the process from setting the substrate to taking out the molded product described in Embodiment 1 is referred to as primary molding, and a molded product formed by the primary molding is referred to as a primary molded product. The process of covering the peripheral layer 121 with the wavelength converting portion 216 formed in the primary molding (that is, the process from setting the substrate to taking out the molded product) is called secondary molding.

[0095] Hereinafter, the structure and manufacturing...

Embodiment approach 3

[0105] Figure 8 It is an external view showing a light emitting device according to a third embodiment of the present invention. This embodiment is characterized in that a rough portion 122 or a recessed portion 123 is formed in advance on the surface of the substrate 111 on which the chip 112 is mounted, and a part of the sealing resin 316 is embedded in the rough portion 122 or the recessed portion 123 . Therefore, the sealing resin 316 and the substrate 111 are more firmly bonded by the anchoring effect.

[0106] According to this embodiment, the sealing resin 316 is directly bonded to the substrate 111 without applying a primer. Of course, a primer can also be applied. In addition, the recessed portion 123 may penetrate the substrate 111 or may not penetrate the substrate 111 .

[0107] Regarding the method of forming the rough portion 122 or the depressed portion 123 on the substrate 111, for example, in the manufacturing process of the substrate 111, corresponding to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com