Double sided acrylic adhesive tapes and their usage

An acrylic, double-sided technology for use in adhesives, film/sheet adhesives, synthetic resin layered products, etc. to solve problems such as breakage, elongation, and poor workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

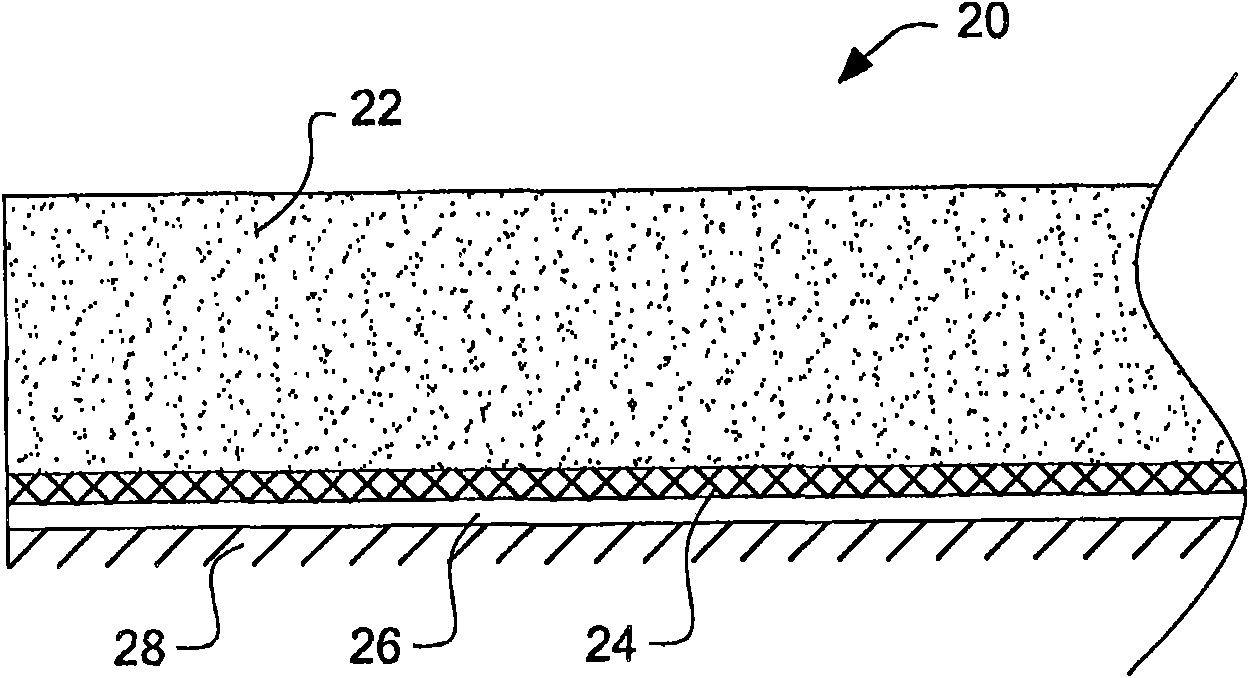

[0067] figure 2 is a cross-sectional view of a double-sided acrylic foam tape (20) having a base layer (PET layer) according to the first embodiment of the present invention. Such as figure 2 As shown, a base layer (24) is provided below the lower surface of the acrylic foam layer (22) having a thickness of 0.1 mm to 4 mm, and below the base layer (24), a pressure sensitive adhesive layer (26) is provided. Below the pressure-sensitive adhesive layer (26), a release film (28) is provided. Since the acrylic foam layer (22) itself is also self-adhesive, it functions as a double-sided adhesive tape. The acrylic foam layer (22) further serves as an impact absorbing layer due to its cushioning effect against external impact.

[0068]Hereinafter, a method for preparing a double-sided acrylic foam tape (20) having a base layer according to a first embodiment of the present invention is described. First, by utilizing functional acrylic acid (ester) monomers such as acrylic acid, an...

Embodiment 2

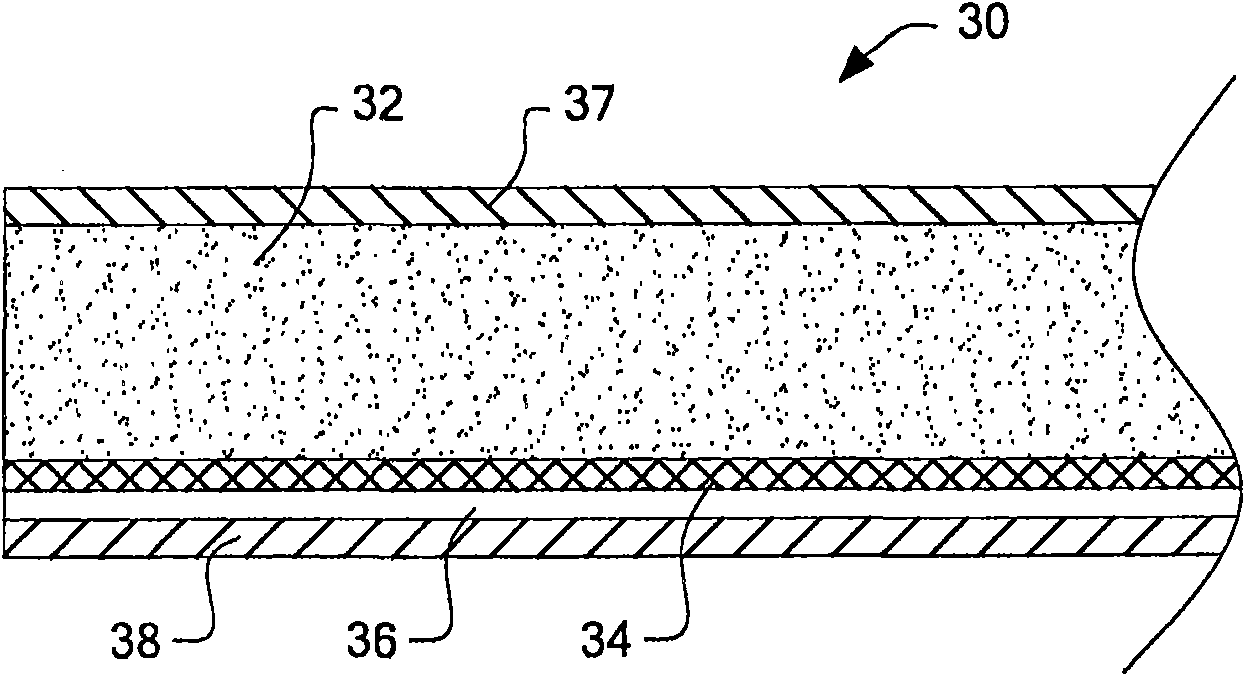

[0092] image 3 is a cross-sectional view of a double-sided acrylic foam tape (30) with a base layer according to a second embodiment of the present invention. Such as image 3 As shown, a base layer (34) is provided under the lower surface of the acrylic foam layer (32) having a thickness of 0.1mm-4mm, and under the base layer (34), a second pressure-sensitive adhesive layer (36) is provided. Below the second pressure sensitive adhesive layer (36), a release film (38) is provided. In order to achieve stronger adhesion, a first pressure sensitive adhesive layer (37) is provided on the upper surface of the acrylic foam layer (32). If desired, the first pressure-sensitive adhesive layer (37) may be mixed with various pigments (translucent, red, gray, etc.), or spices (eg, fruit, pine, herbs, etc.) may be added.

[0093] image 3 The preparation method of the shown double-sided acrylic foam tape (30) is similar to the method described in the foregoing Example 1, so a detailed...

Embodiment 3

[0095] Figure 4 is a cross-sectional view of a double-sided acrylic foam tape (40) with a base layer according to a third embodiment of the present invention. Such as Figure 4 As shown, the base layer (44) is provided under the lower surface of the first acrylic foam layer (42) having a thickness of 0.2 mm to 0.6 mm, and under the base layer (44), a second acrylic foam layer ( 43). Below the second acrylic foam layer (43), a release film (48) is provided.

[0096] Figure 4 The preparation method of the shown double-sided acrylic foam tape (40) is similar to the method described in the foregoing Example 1, so a detailed description of the preparation method is omitted here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap