Flapped rudder transmission device

A technology of transmission device and flap rudder, which is applied in directions such as rudder steering and steering, can solve problems such as difficult installation and disassembly, high manufacturing cost, and poor rudder efficiency, and achieves easy installation and disassembly, convenient refueling and maintenance, and reduced manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

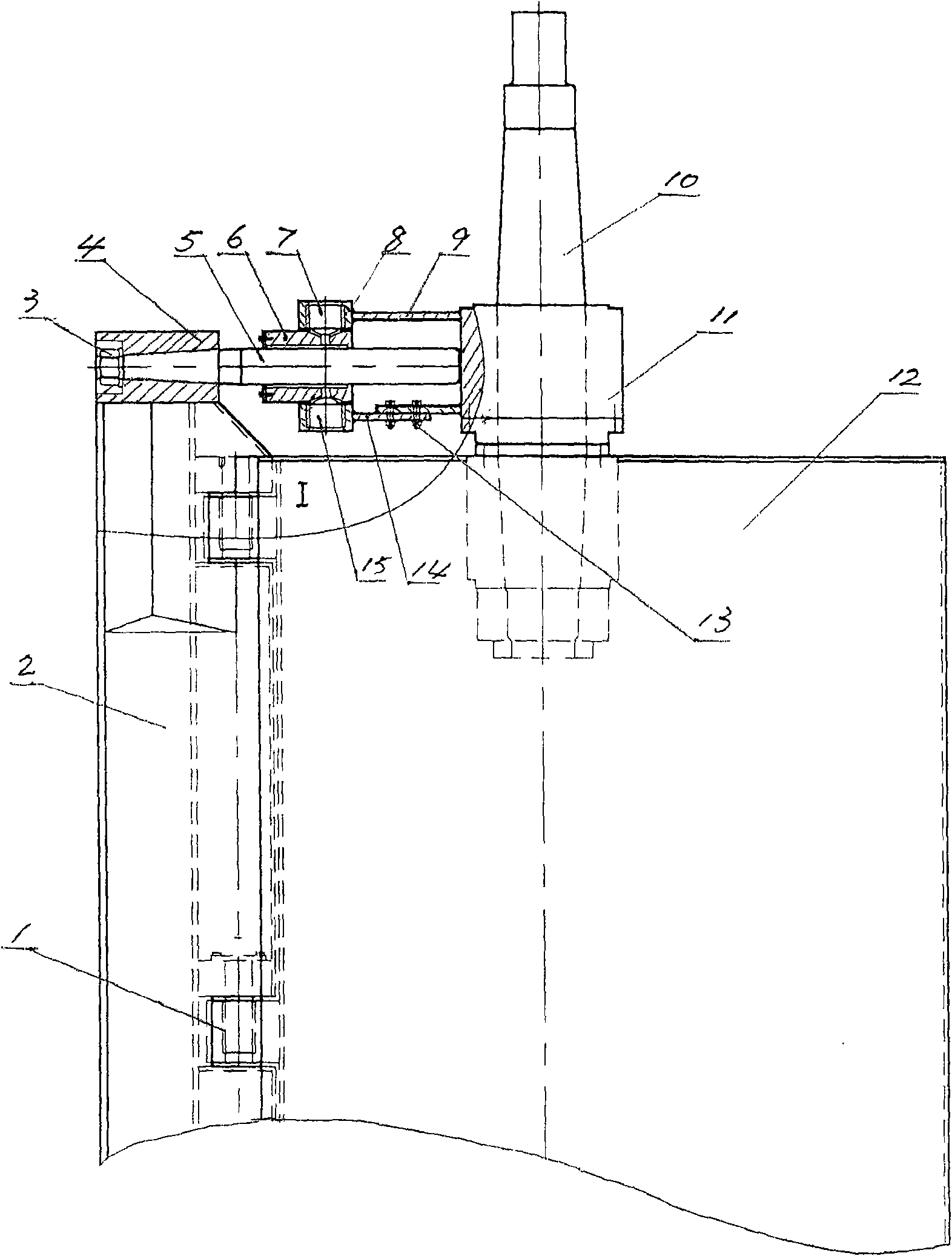

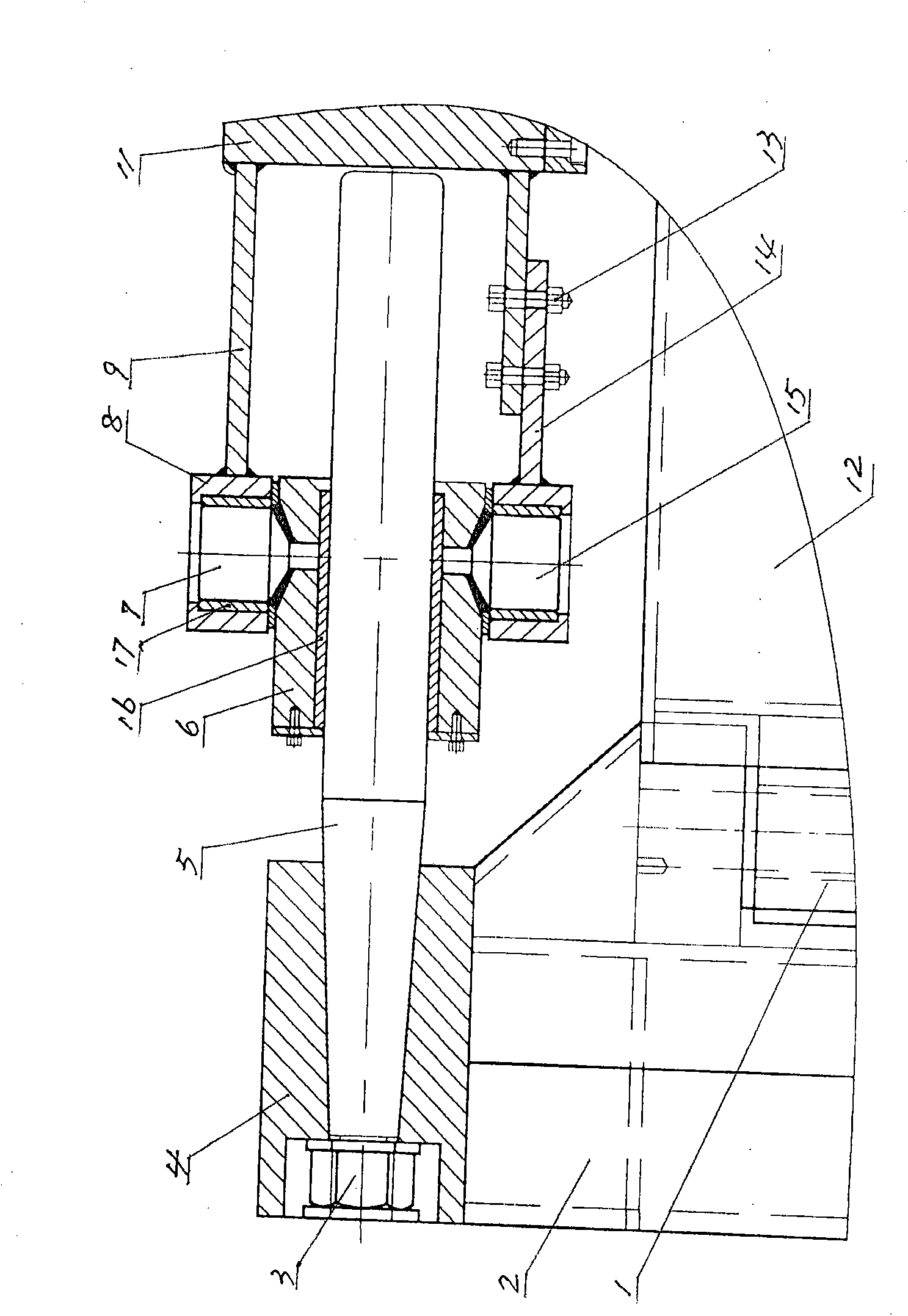

[0014] Such as figure 1 and figure 2 As shown, the flap rudder transmission device of the present invention contains a mother rudder 12 and a child rudder 2, and the longitudinal outer side of the mother rudder 12 and the longitudinal inner side of the child rudder 2 are hinged together by a pin seat 1 and a pin shaft, so that the mother rudder 12 and the child rudder are hinged together. The two rudders are hinged together in a parallel and rotating shape. The upper end of the mother rudder 12 is provided with a rudder stock 10 , and the lower end of the rudder stock 10 is fixedly connected with the mother rudder 12 . The outside of the rudder stock 10 is covered with a sleeve 11 and there is a movable fit between the two. A guide rod 5 is arranged between the upper end of the sub-rudder 2 and the sleeve 11, and a fixed block 4 is welded on the upper end of the sub-rudder 2. A tapered hole is processed on the fixing block 4 , and the tapered hole faces the sleeve 11 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com