Rapid positioning platform based on collinear flexible assembly of a plurality of power assemblies

A powertrain and positioning platform technology, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems that the powertrain cannot meet the requirements of collinear flexible assembly and cannot be shared

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] This embodiment is used to explain the claims of the invention, and the protection scope of the invention is not limited to the structures described below. Those skilled in the art make structural changes different from the following in the technical solution of the present invention, all of which belong to the protection scope of the present invention.

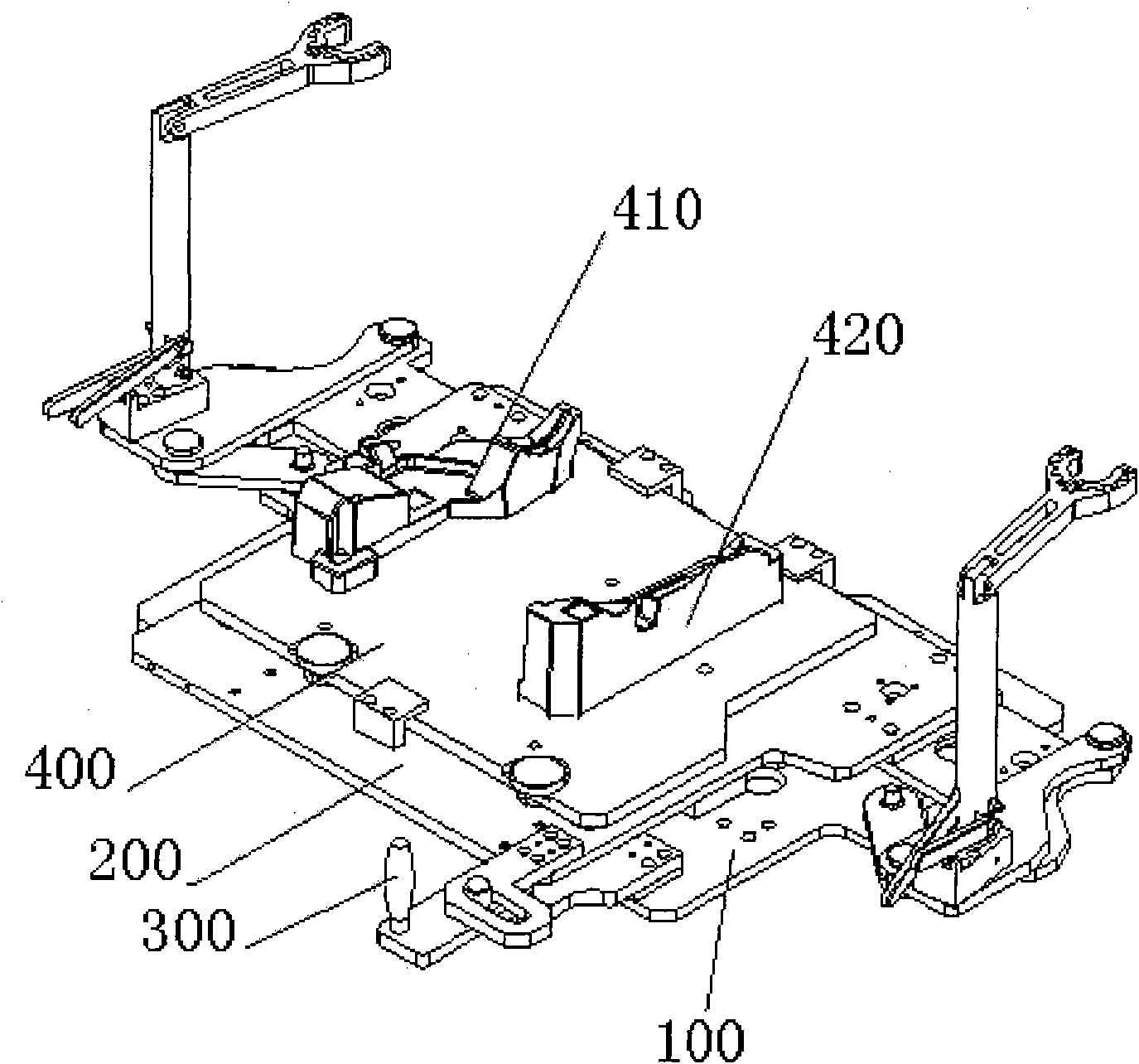

[0018] like figure 1 , 8 As shown, the fixed base 100 is provided with a movable base 200 which can move in a straight line, and a half-sine manual crank mechanism 300 is connected between the movable base 100 and the fixed base 200 , and the movable base 100 is provided with a floating base 400 .

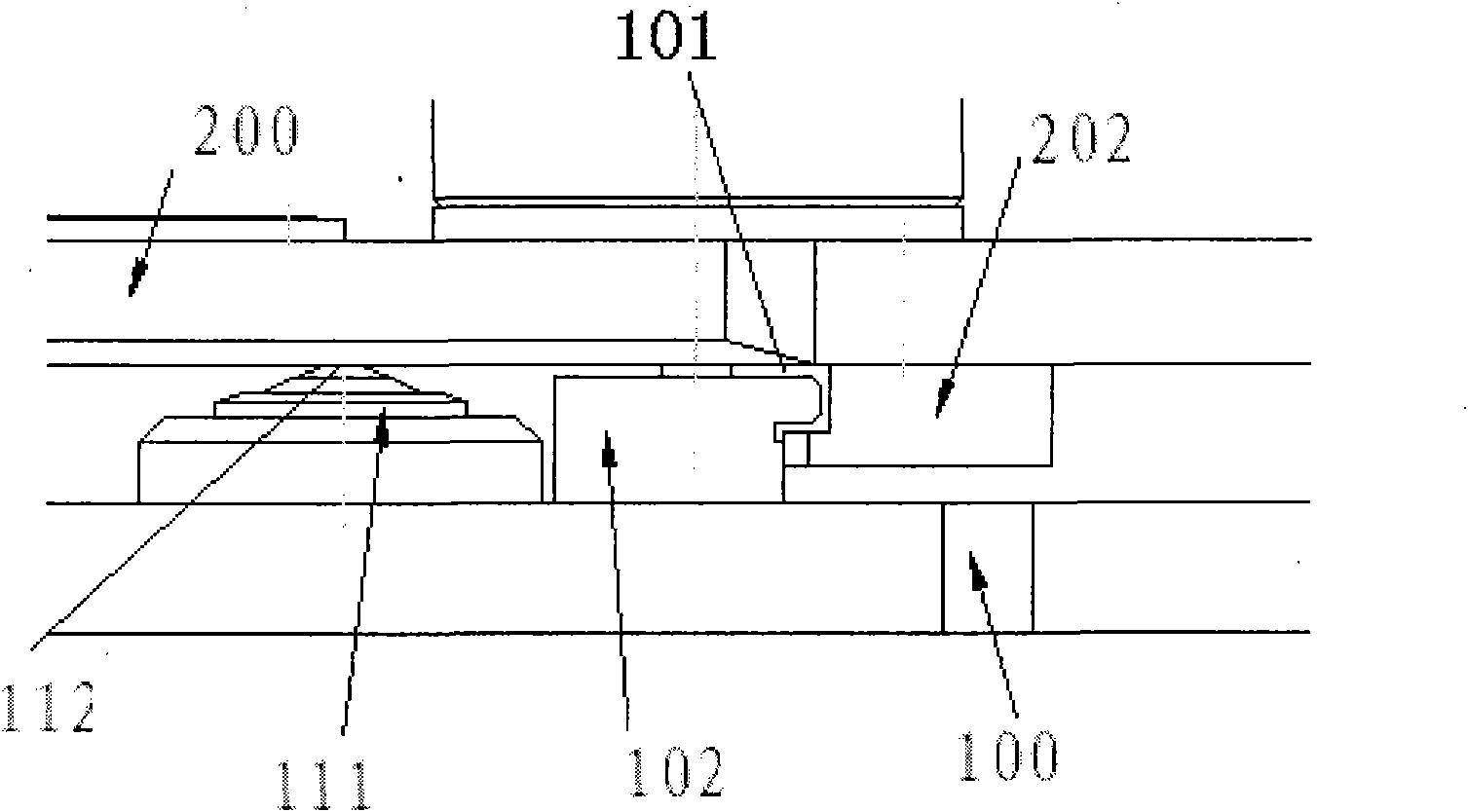

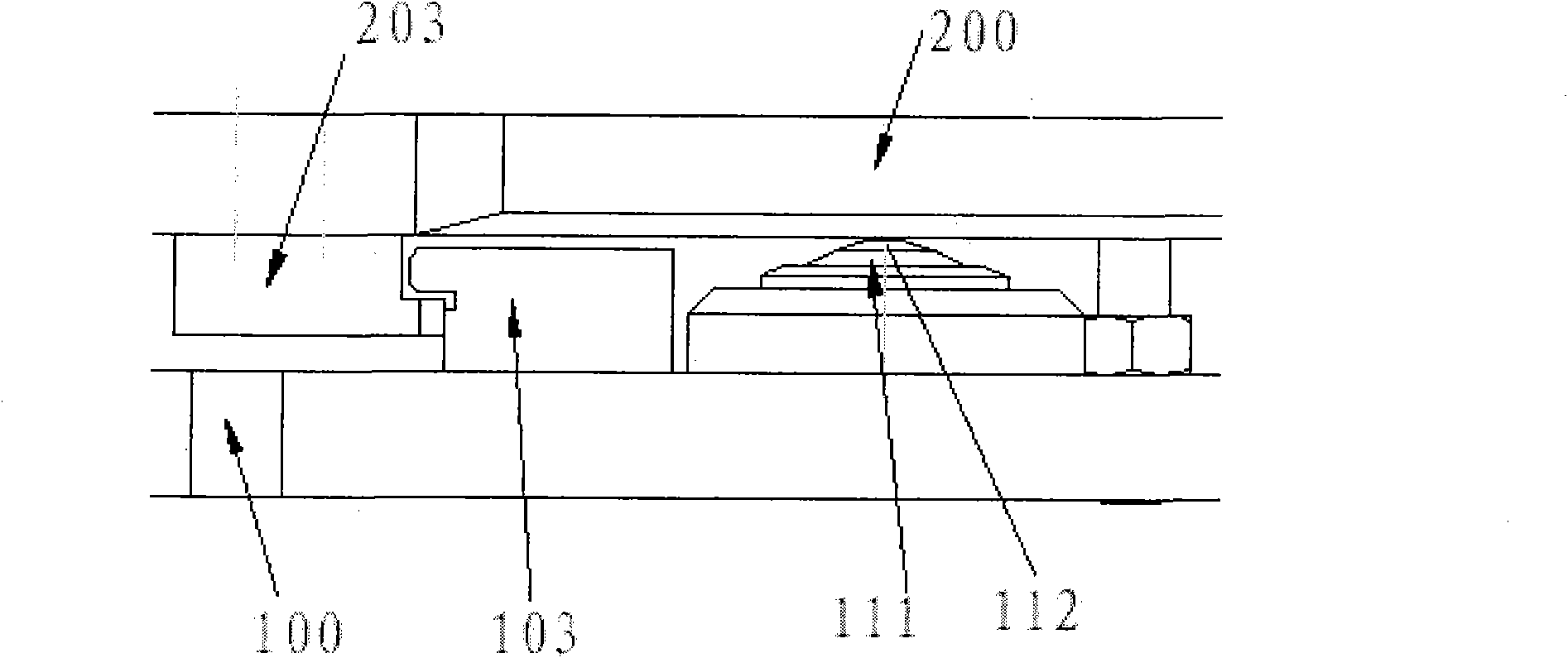

[0019] Split guide rails are provided between the fixed base plate and the movable base plate, and planar support devices for supporting the movable base plate are distributed on the fixed base plate. like figure 2 , 3 As shown, the fixed bottom plate 100 is fixed on the assembled trolley on the assembly line (not show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com