Constant speed control device of mixer truck, mixer truck and method for controlling constant rotating speed of mixing drum

A technology of constant speed control and mixer truck, which is applied in control devices, cement mixing devices, clay preparation devices, etc., can solve the problem of not being able to ensure economical efficiency, adaptability to the rotation stability of the mixing drum at the same time, difficult to meet the constant speed control of the mixing drum, The control system is complex and other problems, so as to avoid fluctuations, improve adaptability and high economic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

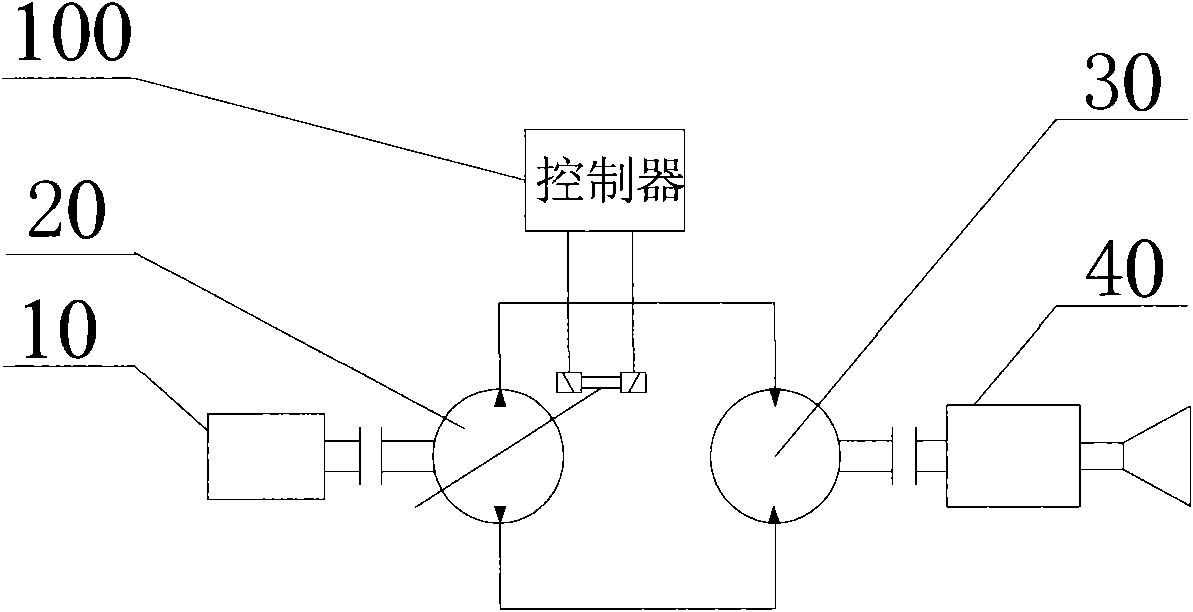

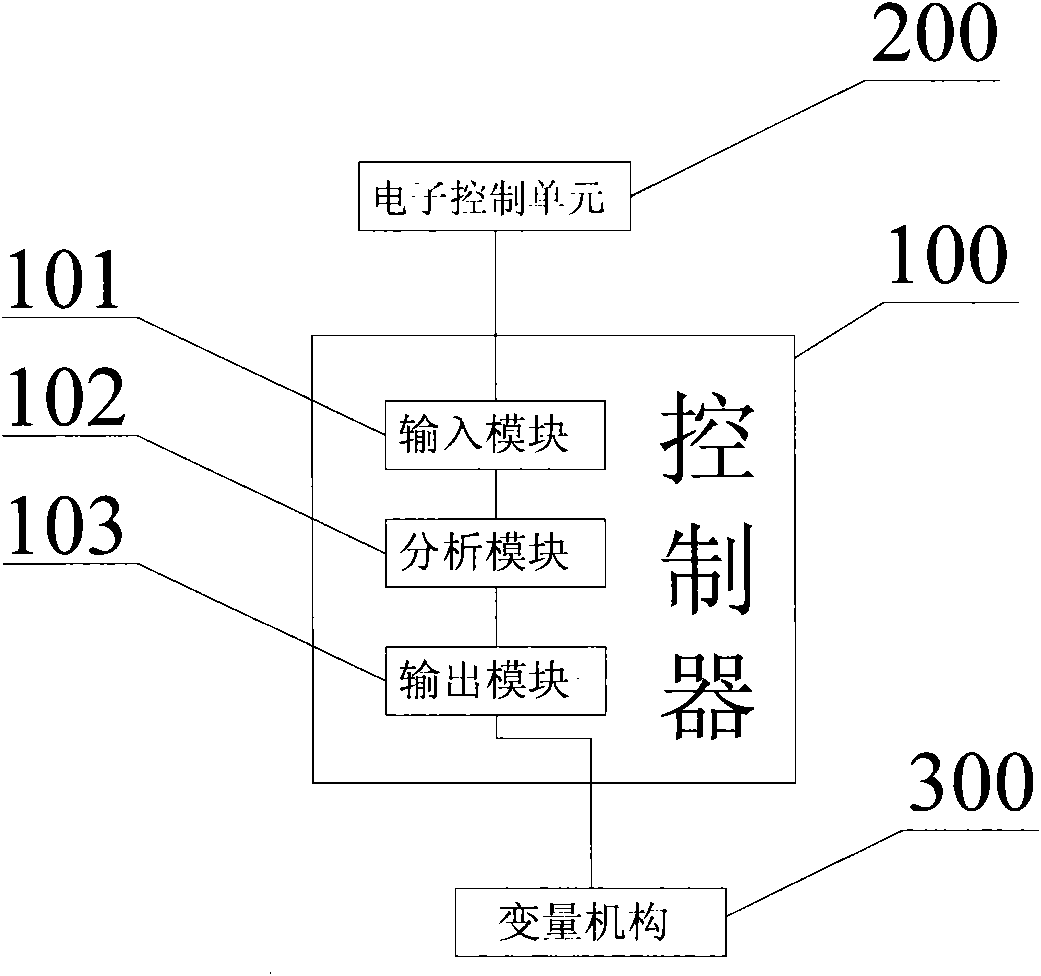

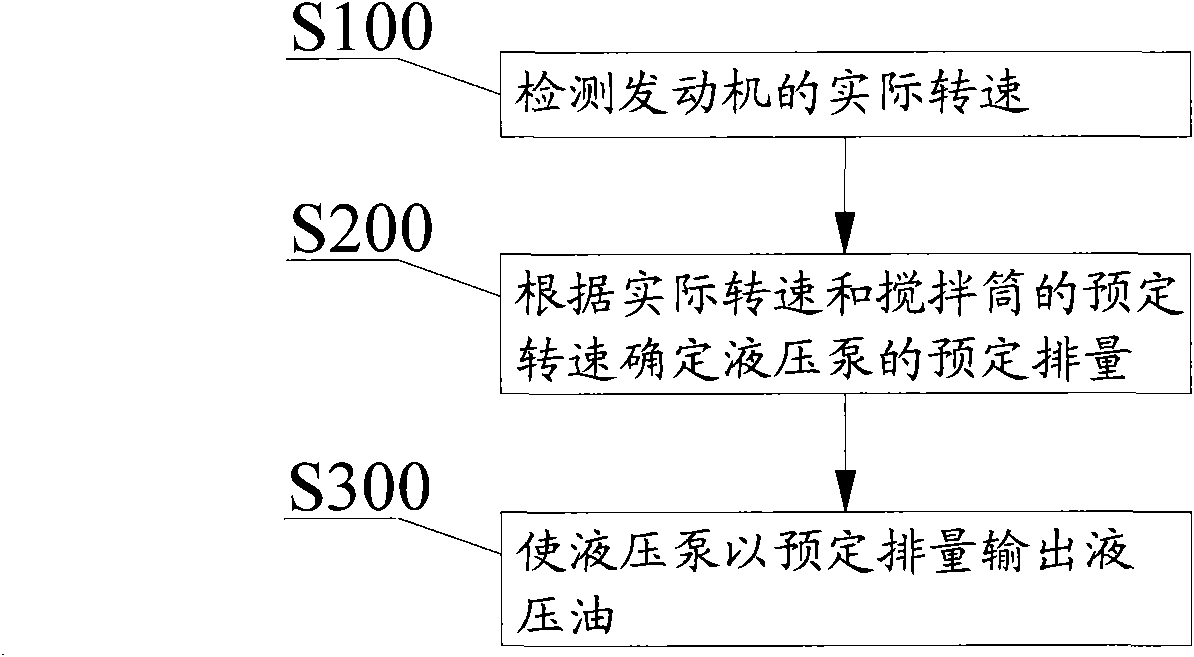

[0047] The mixer truck constant speed control device provided in Embodiment 1 includes a hydraulic system, and the hydraulic system includes a hydraulic pump 20, a hydraulic motor 30 and a controller 100. For clarity, figure 1 The engine 10 and the mixing drum 40 are also shown in the figure; the hydraulic pump 20 is driven by the engine 10 of the mixer truck, and the hydraulic pump 20 is connected with the hydraulic motor 30 through a hydraulic oil circuit, and the hydraulic motor 30 is used to drive The mixing drum 40 of the mixer truck rotates; figure 2 As shown, the controller 100 includes an input module 101, an analysis module 102 and an output module 103, the input module 101 is connected to the engine 10 of the mixer truck, and outputs the actual speed of the engine 10 to the analysis module 102, and the analysis module 102 is based on The actual rotational speed of the engine 10 and the predetermined rotational speed of the mixing drum 40 obtain the predetermined dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com