Explosion-proof sheet and explosion-proof structure and power battery of explosion-proof sheet

An explosion-proof structure, power battery technology, applied in the direction of structural parts, battery pack components, circuits, etc., can solve the problems of difficulty in ensuring the reliability of explosion-proof performance, failure to meet battery safety requirements, and difficulty in controlling the depth of indentation, etc., to achieve Low processing cost, simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

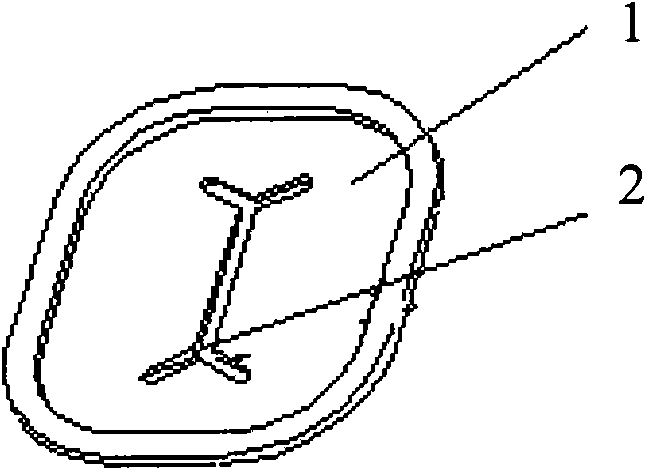

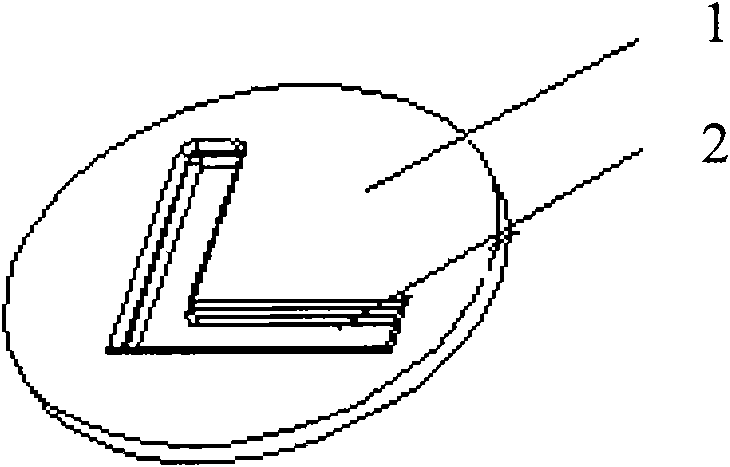

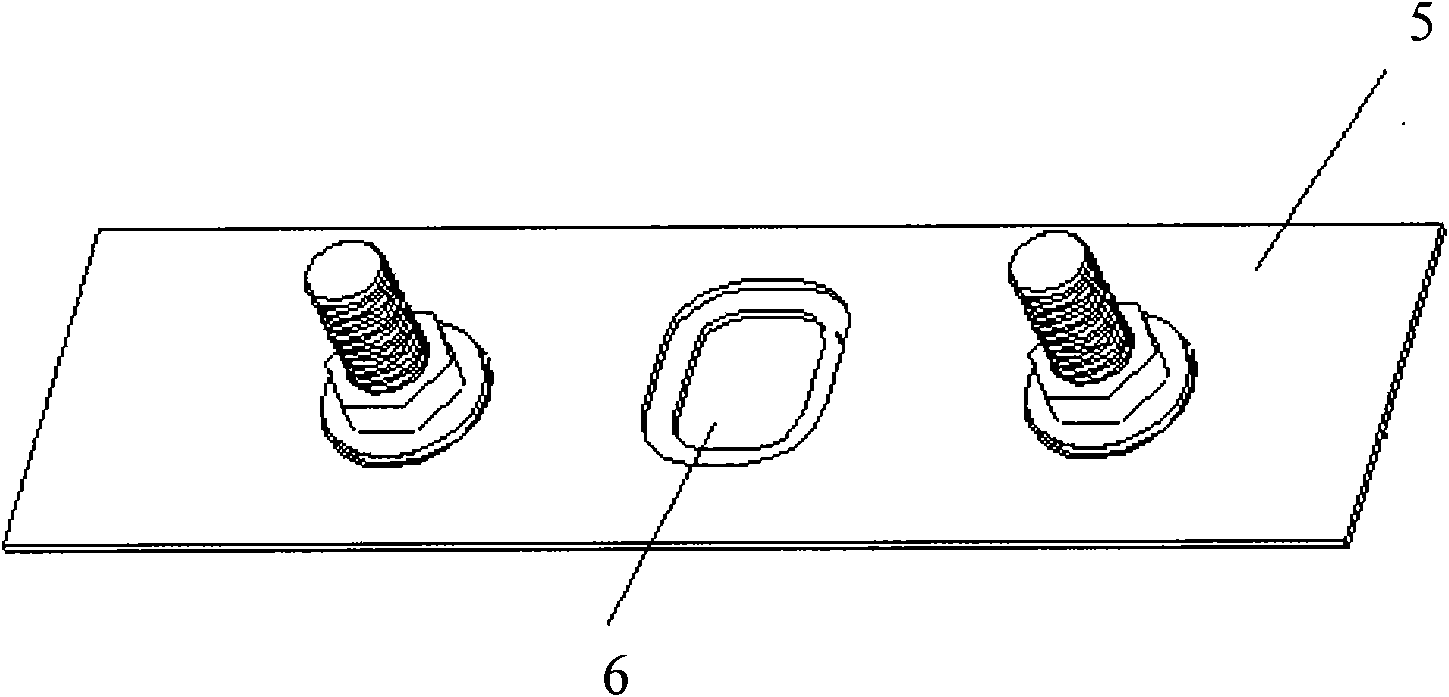

[0016] Such as figure 1 As shown, as an embodiment of the present invention, explosion-proof indentation 2 is processed on the explosion-proof sheet 1 of the present invention, and the material of the explosion-proof sheet 1 and the battery cover plate 5 can be the same, such as aluminum alloy or pure aluminum. The explosion-proof disc 1 is in the shape of a rectangle with rounded corners and a thickness of 0.2-0.4mm. The shape of explosion-proof indentation 2 is shape, the depth of explosion-proof indentation 2 is 0.01-0.03mm. to combine image 3 and Figure 4 As shown, the cover plate 5 of the power battery is provided with an exhaust opening 6 for placing the explosion-proof disk 1, and the explosion-proof disk 1 is placed on the exhaust opening 6, and it is welded by laser or electron beam welding, so that The explosion-proof disk 1 and the cover plate 5 form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com