Hot rolling equipment and method for manufacturing steel product using the hot rolling equipment

A technology of equipment and hot rolling mills, applied in the direction of metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of generating idle time and hindering rolling efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] One embodiment of the present invention will be described with reference to the drawings. In addition, the case where a rolling material is a steel material is demonstrated here as an example.

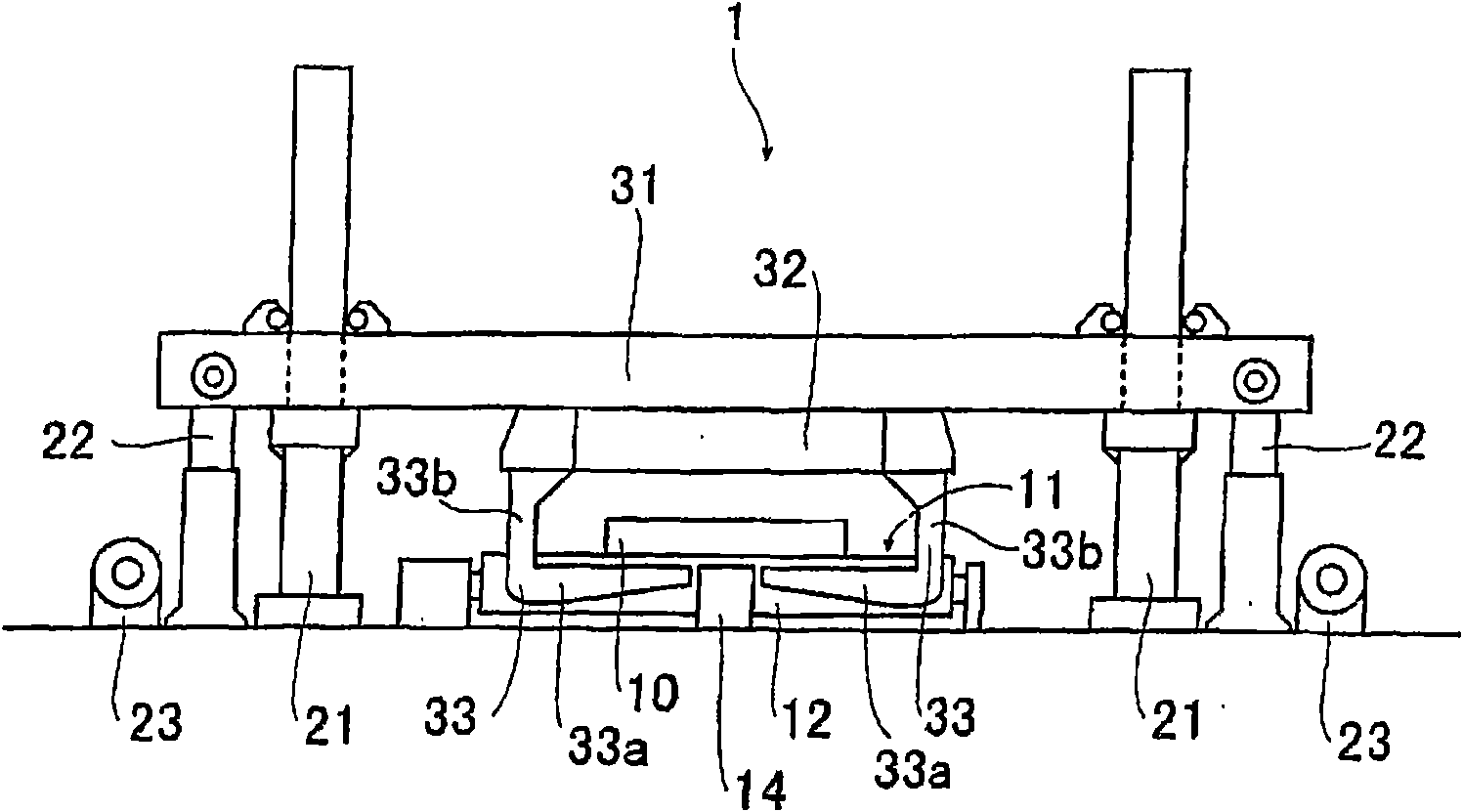

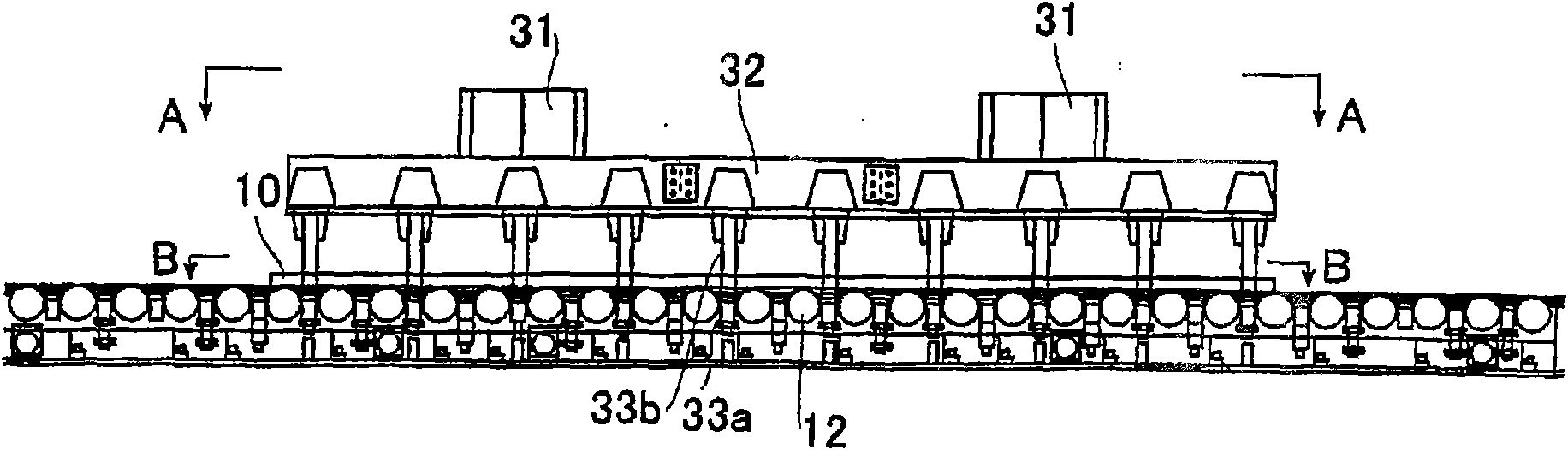

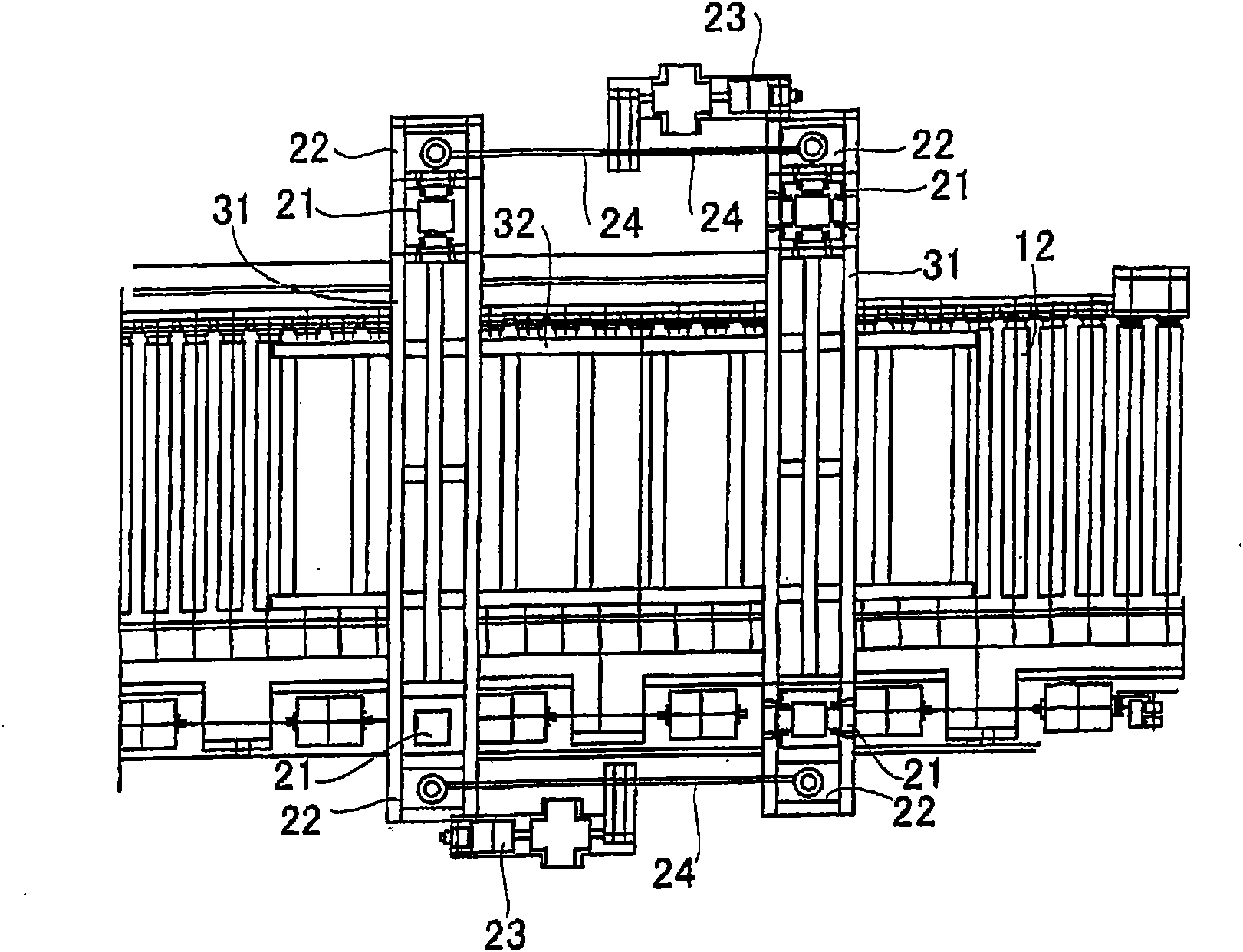

[0077] Figure 1 to Figure 4 A holding device for steel materials according to one embodiment of the present invention is shown. figure 1 main view, figure 2 for the side view, image 3 for figure 2 The diagram of the A-A arrow direction (top view), Figure 4 for figure 2 The diagram in the direction of the B-B arrow (top view).

[0078] Such as Figure 1 to Figure 4 As shown, the steel material holding device 1 according to this embodiment moves the steel material 10 on the conveying roller table (roller table) 11 to a position where the subsequent steel material can pass in hot rolling equipment such as a thick plate rolling equipment, And the holding device of the steel kept in standby state, it comprises: four pillars (support body) 21, are located at the both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com