Protective material having guard plates on clearly visible substrate

A guard plate and base fabric technology, applied in protective clothing, protective equipment, camouflage devices, etc., can solve problems such as incomplete fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

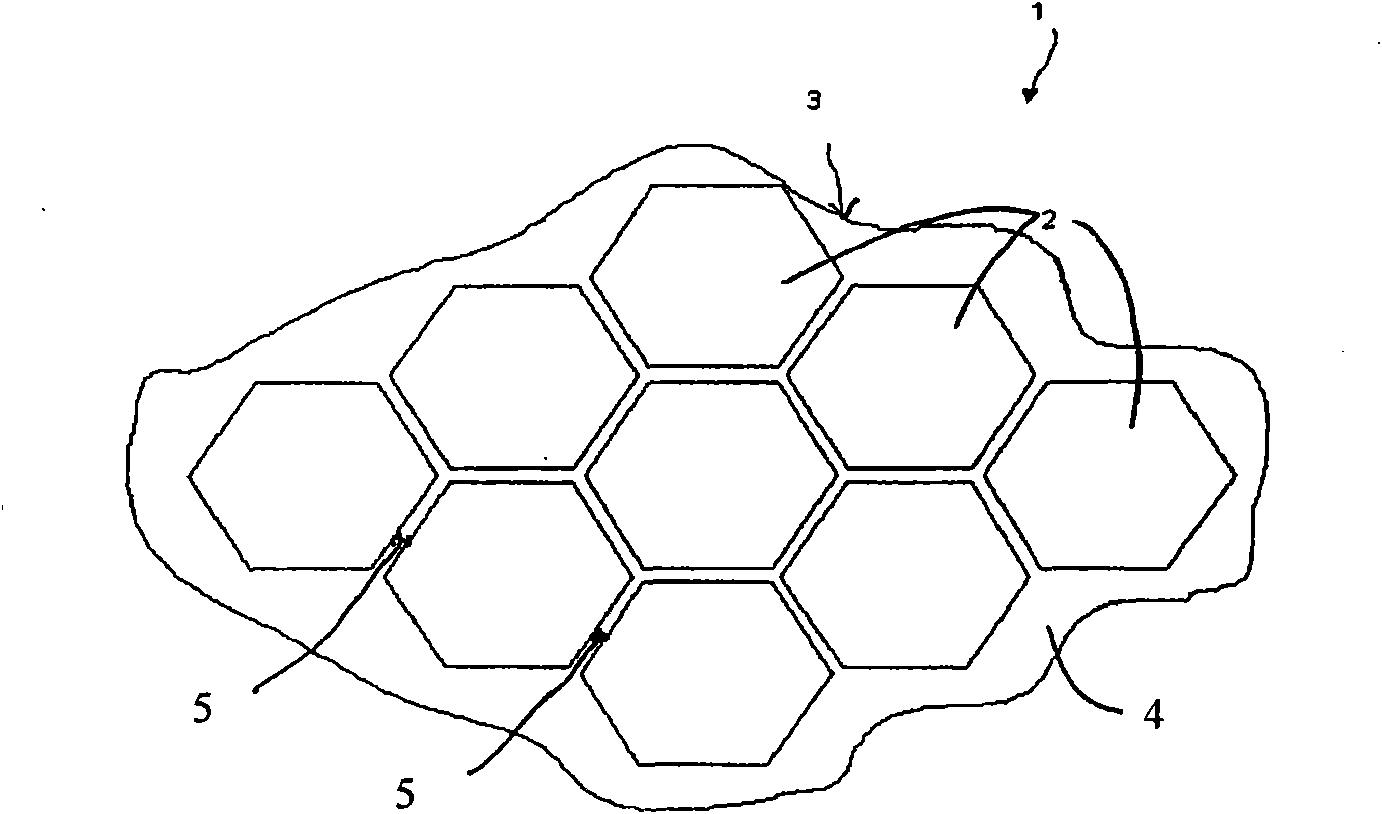

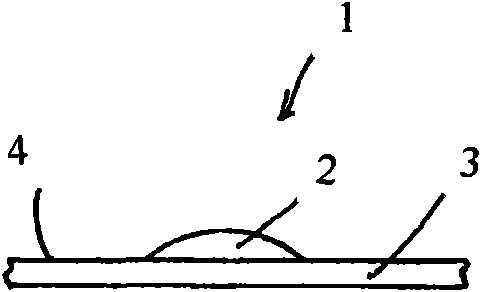

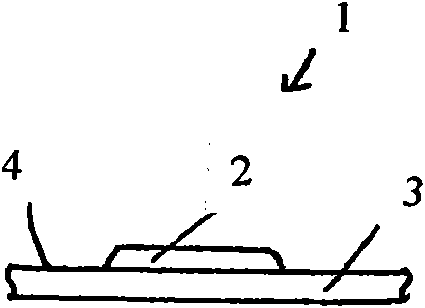

[0023] Figure 1 is a top view of a protective material 1 with a flexible base fabric 3 and spacer panels 2 according to one embodiment of the present invention. The fenders 2 are glued to the first or top surface 4 of the flexible base fabric 3, spaced apart from each other. In the embodiment shown in Fig. 1, the shields 2 are hexagonal in shape, arranged in a regularly repeating pattern. In some other embodiments, the guard plate 2 can be in other shapes, such as circular, square, or any other polygonal shape, and can be arranged in a random or irregular manner to fill the space. In one embodiment, the panels 2 are arranged in a mathematical Penrose tile form. The fenders 2 leave a gap width 5 between adjacent fenders 2 . In other embodiments, the panel 2 assembly includes a variety of different shapes (as shown in Figures 3-4). In the embodiment shown in Fig. 1B, the vertical section of the shield 2 is dome-shaped. In the embodiment shown in Fig. 1C, the vertical section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com