Sackcloth rapier loom

A technology of rapier looms and sackcloth, which is applied in the field of textile looms, can solve the problems of large footprint, complex structure, and high cost, and achieve the effects of reducing energy consumption, avoiding inconsistent degrees of tightness, and reducing man-hour costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

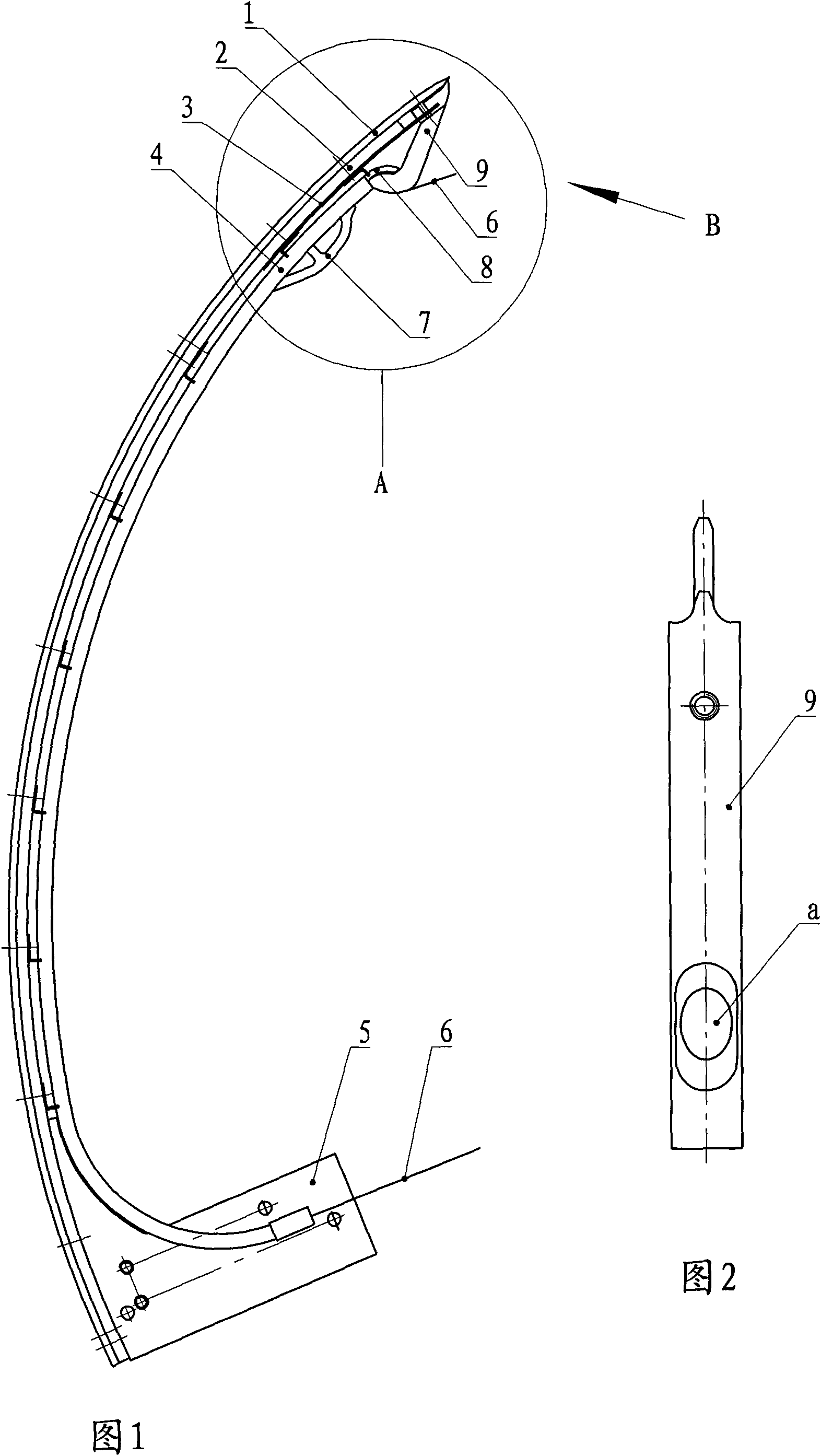

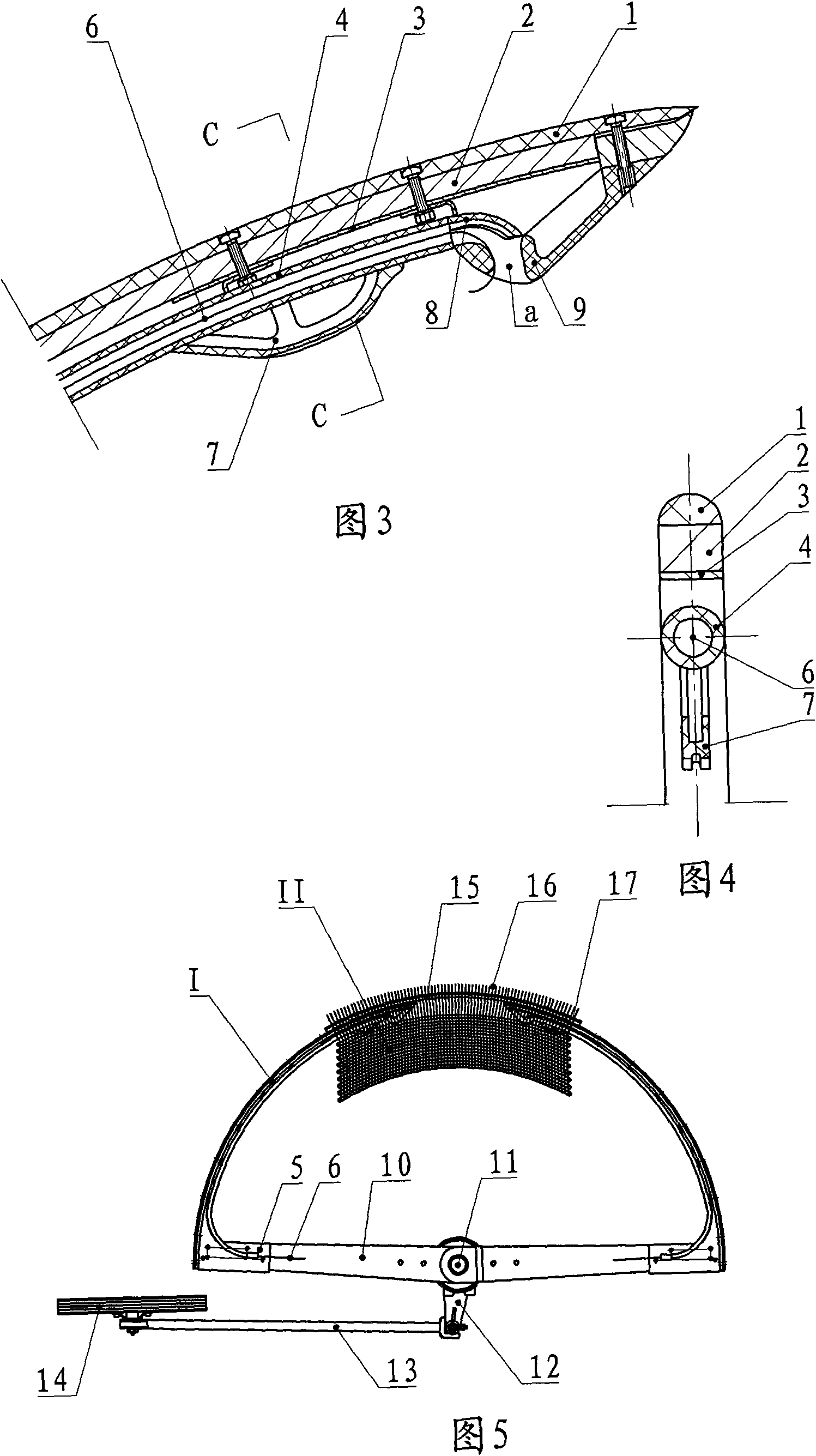

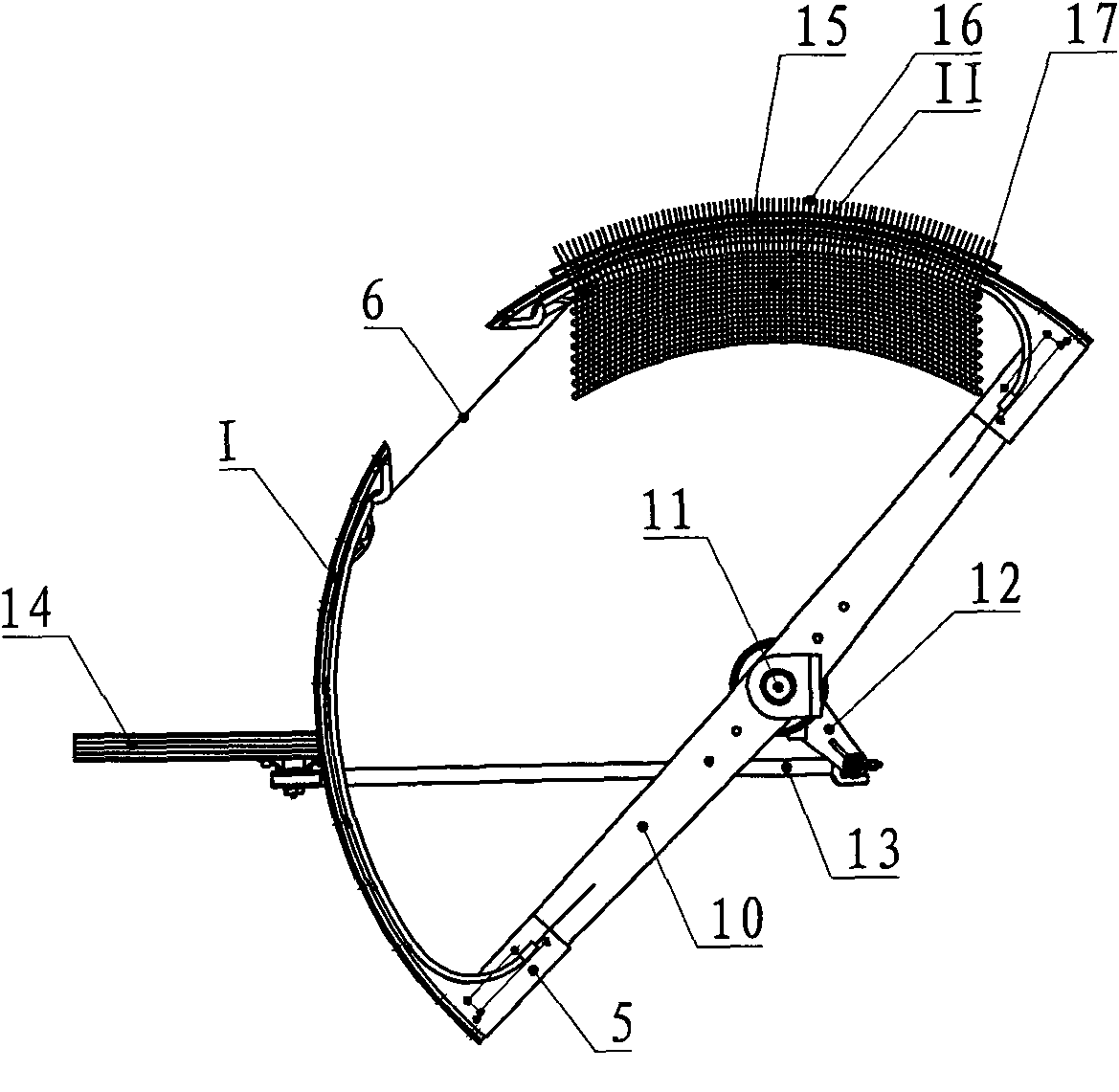

[0016] The used rapier device of the sackcloth rapier loom of the present invention is an arc rapier device. Said arc rapier device such as figure 1 , 2 , 3, and 4, it is composed of curved rapier strip 1, curved rapier strip 2, rapier tube 4, rapier mouth plate 3, rapier head 9, yarn guide 7, and rapier drive plate 5 of. The outer side of the arc-shaped rapier bar, that is, the bow back is covered with an arc-shaped rapier lining strip, and the outer edge of the radial section of the arc-shaped rapier lining strip is a circular arc, which makes the rapier bow back smooth. The rapier tube is installed on the inside of the curved rapier bar, that is, on the belly of the bow, and is a tube with a smooth inner wall. One end of the arc-shaped rapier bar is fixedly installed with a rapier drive plate, or in other words, one end of the arc-shaped rapier bar is fixed on the rapier drive plate, and the rapier head is on the other end of the arc-shaped rapier bar. The end of the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com