Design method of V-shaped transmission belt and belt wheel

A design method and transmission belt technology, applied to V-shaped belts, transmission devices, components with teeth, etc., can solve problems such as tooth gnawing, wrong design principles, and short belt life, and achieve ideal results and improve use. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The design method of the power transmission belt of embodiment 1 ¢ 250cm specification and pulley, uses CAD software to carry out on the computer.

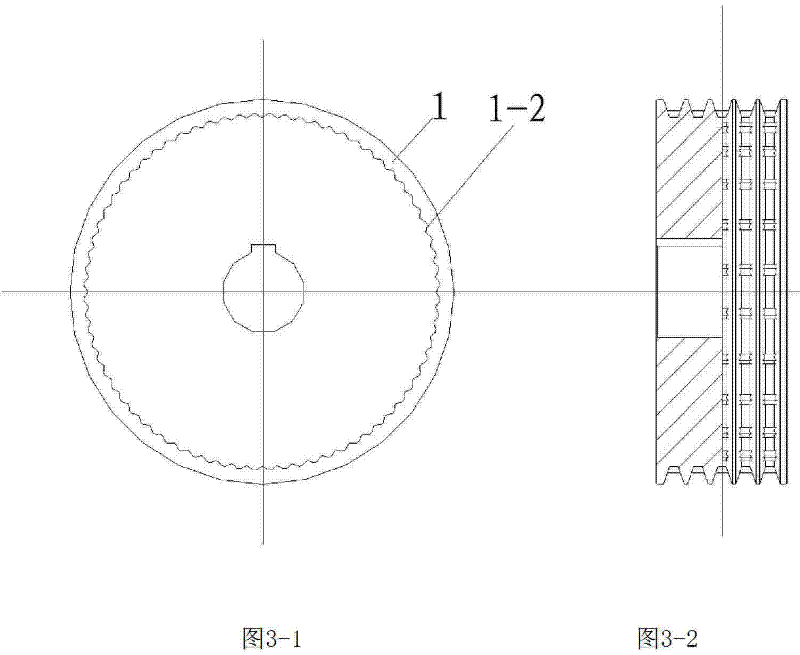

[0036] 1) According to the parameters required by the 250cm specification, and according to the principle of meshing transmission, first design a five-row V-shaped transmission belt 2 with concave-convex teeth on the inner diameter surface as circular arc teeth, as shown in Figure 3. Its V-shaped angle is 38 degrees, and its arc tooth profile curve is represented by thin solid line 2-1;

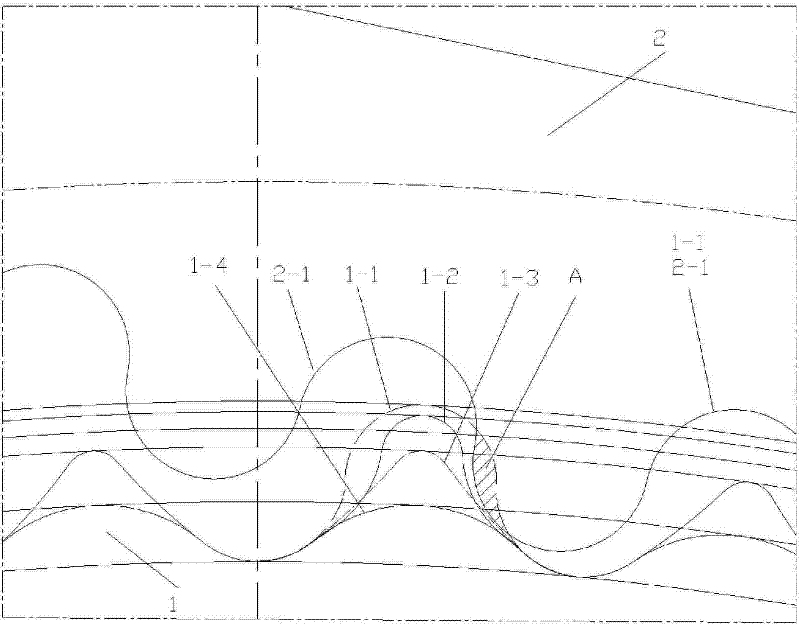

[0037] 2) According to the principle of meshing transmission, arc teeth meshing with the concave and convex teeth 2-1 of the transmission belt 2 are designed at the bottom of the five-row pulley 1 with V-shaped wheel grooves. -1 means; that is, the dotted line 1-1' coincides with the thin solid line 2-1;

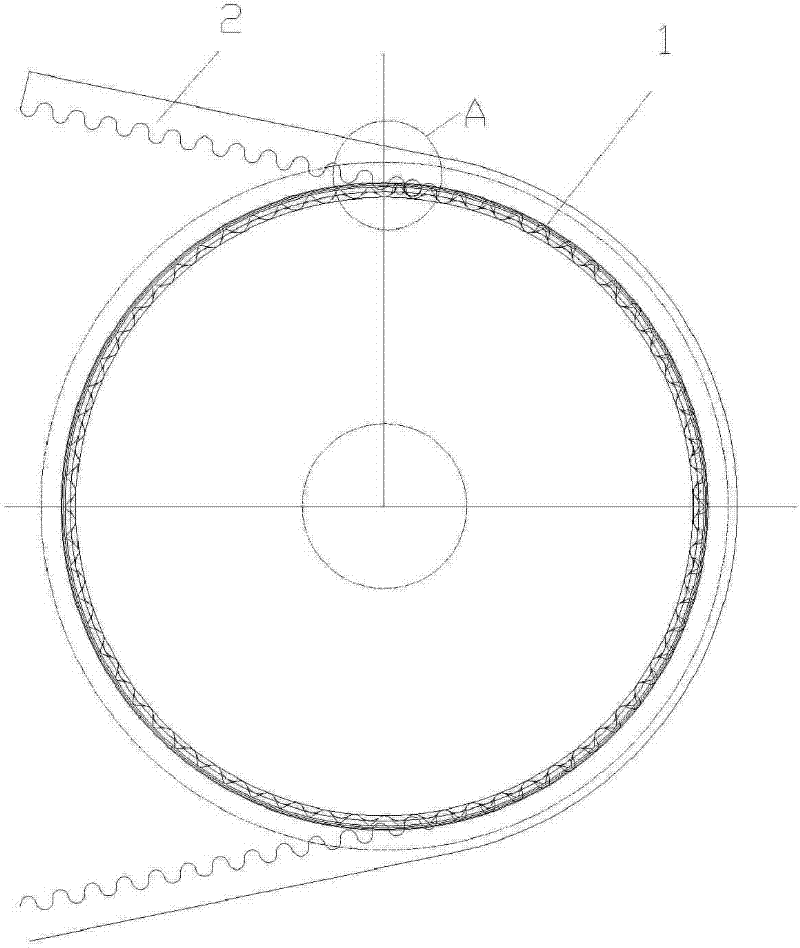

[0038] 3) see figure 1 , mesh the transmission belt 2 with the pulley 1 in the figure according to the working state, see figure 2 ...

Embodiment 2

[0040] Embodiment 2 The design method of the driving belt and pulley of ¢ 250cm specification, uses CAD software to carry out on the computer.

[0041] Steps 1), 2), and 3) are the same as the above example, seefigure 1 ,image 3.

[0042] 4) Reduce the circular arc convex teeth of the pulley 1 radially to low circular arc convex teeth that do not interfere with the concave and convex teeth of the transmission belt (the tooth profile curves are represented by thin solid lines 1-4, see figure 2 ), and used for the circular arc convex tooth design of the full pulley, and the rest remains unchanged, so that the concave and convex teeth of the pulley are - arc concave teeth - short arc convex teeth - arc concave teeth - short arc convex teeth - head and tail connected, evenly distributed. This promptly obtains the design product of another driving belt and pulley of ¢ 250cm specification.

Embodiment 3

[0043] Embodiment 3 The design method of the long concave-tooth transmission belt and pulley of ¢280mm specification is carried out using CAD software on a computer.

[0044] 1) According to the parameters required by the 280cm specification, and according to the principle of meshing transmission, first design a five-row V-shaped transmission belt 2 with concave and convex teeth on the inner diameter surface as circular arc teeth. The concave and convex teeth are continuously and evenly distributed, see Figure 4 ;The V-shaped angle is 38 degrees;

[0045] 2) According to the principle of meshing transmission, arc concave-convex teeth meshing with the concave-convex teeth 2-1 of the transmission belt 2 are designed on the groove bottom of the five-row pulley 1 with V-shaped grooves. The concave-convex teeth are continuously and evenly distributed, see Figure 4 .

[0046] 3) see Figure 4 , mesh the transmission belt 2 with the pulley 1 according to the working state on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com