Method for accurately distinguishing overflow signal of soymilk grinder and food processor in heating process

An overflow signal and accurate identification technology, applied in the direction of program control, computer control, electrical program control, etc., can solve the problems of overcooking, unable to make a correct judgment on overflow signal, and affect the cooking effect, so as to prevent false overflow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with accompanying drawing (embodiment):

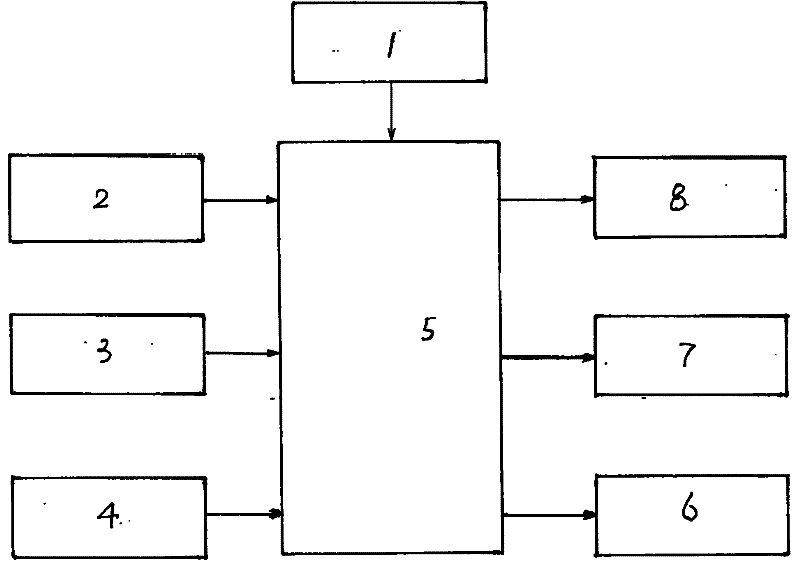

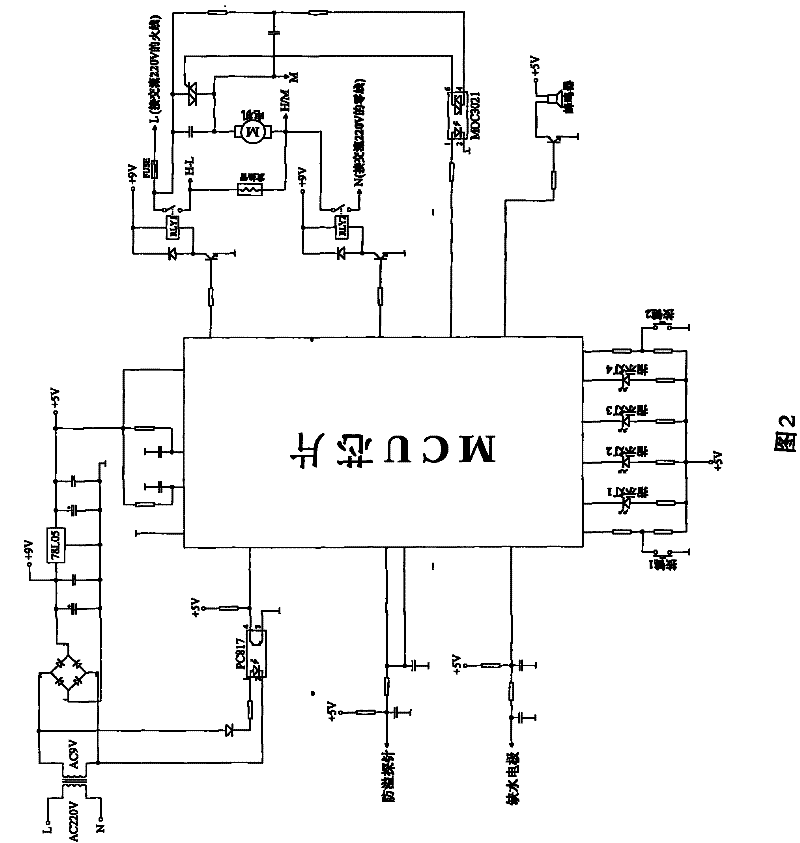

[0010] refer to figure 1 , figure 2 , the implementation of the present invention needs to include the following circuits: rectification filter circuit 1, anti-overflow detection circuit 2, water shortage detection circuit 3, button and indication circuit 4, control circuit 5, motor drive circuit 6, heat pipe drive circuit 7, buzzer drive circuit 8.

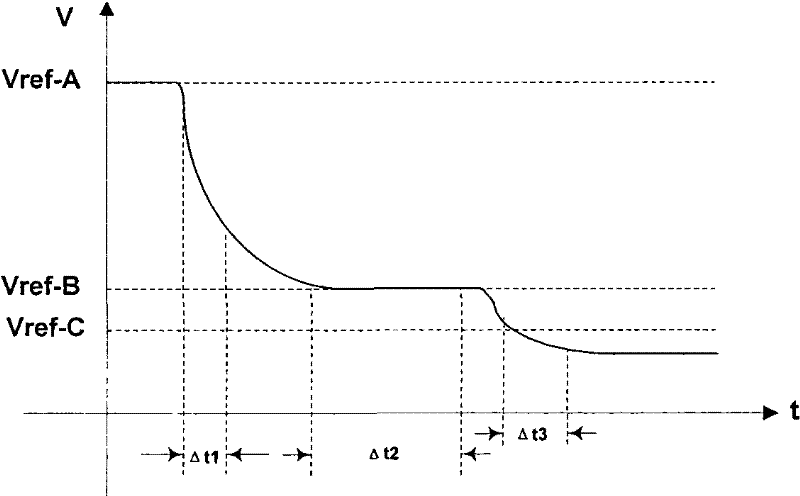

[0011] After the soymilk maker is energized and works, the water shortage detection circuit 3 detects whether the soymilk maker is short of water when the soymilk maker is working, and stops all work and reports to the police if it is short of water. The anti-overflow detection circuit 2 always detects whether there is an overflow signal in the soymilk machine. When an overflow voltage signal occurs, the anti-overflow probe received by the single-chip microcomputer (MCU) integrated chip in the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com