Method for preparing milk glass bottle

A glass bottle and milky white technology, applied in the field of inorganic materials, can solve problems such as insufficient whiteness, large glass stress, and limited usage, and achieve the effects of improving taste and taste, good mellowness and aging, and high qualified rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] A method for preparing milky glass bottles, mainly based on mineral raw materials and chemical raw materials, the mineral raw materials are 170g of quartz sand, 215g of feldspar, 10g of calcite, and 11g of dolomite; the chemical raw materials are 12g of sodium nitrate and 53g of sodium fluorosilicate , soda ash 58g, clarifying agent 3.3g, the concrete steps of described method are:

[0037] The first step is to prepare raw materials;

[0038] The second step raw material inspection;

[0039] The third step is weighing proportioning;

[0040] The fourth step is mixing;

[0041] The fifth step is to raise the furnace head bin;

[0042] The sixth step is melting in constant temperature electric furnace;

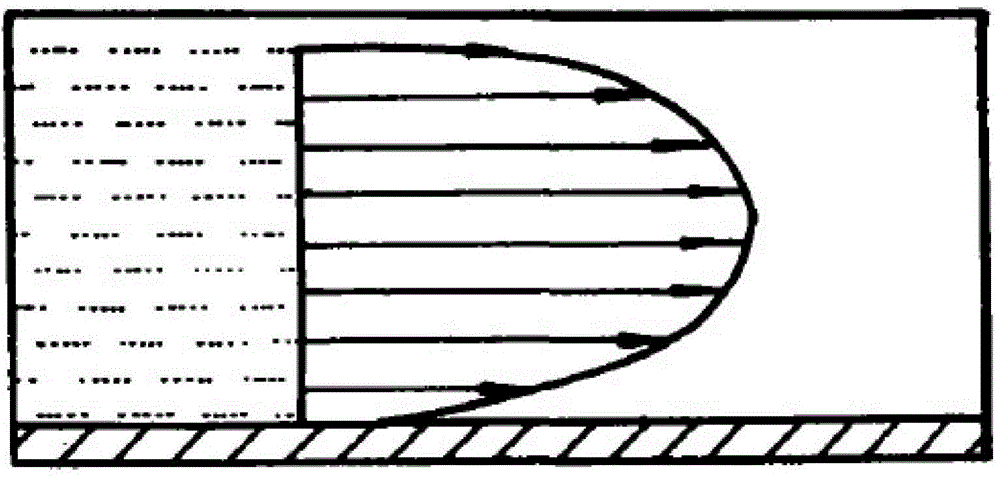

[0043] The seventh step is machine forming;

[0044] The eighth step bottle mouth manual machine molding;

[0045] Ninth step annealing;

[0046] The tenth step is to inspect the packaging.

[0047] The electric furnace melting temperature in the sixth step is 148...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com