Suction and delivery water assembly

A technology of suction and drainage and components, applied in soil drainage, application, construction, etc., can solve problems such as easy blockage failure, blind pipe drainage failure, retaining wall collapse, etc., and achieves difficult soil blockage, high drainage efficiency and long service time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

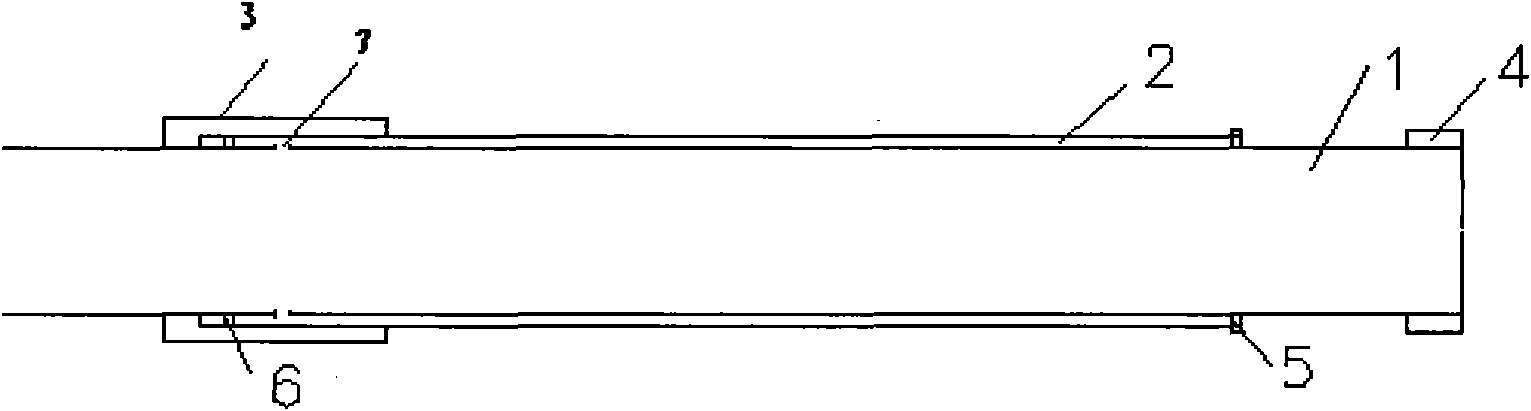

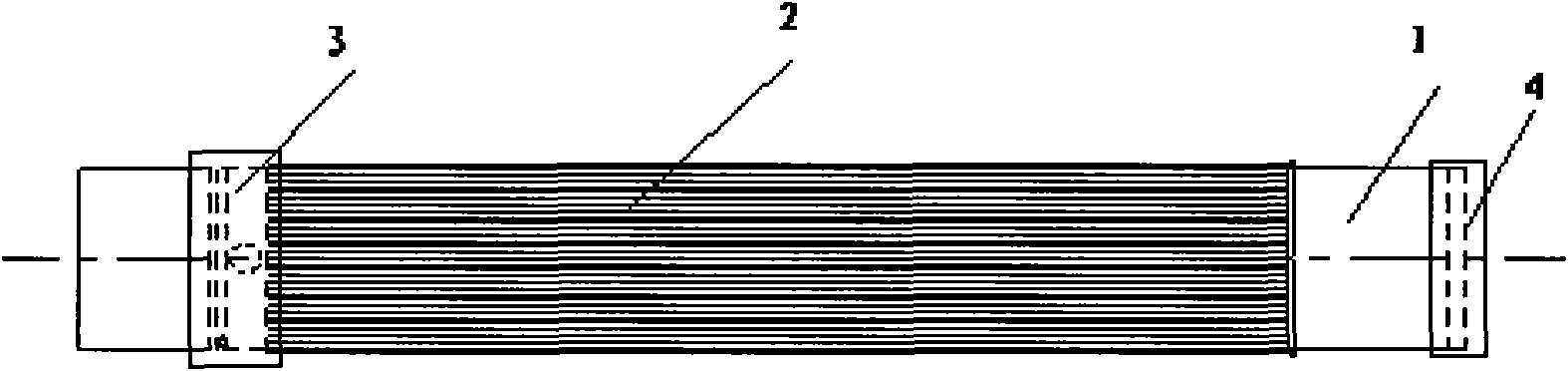

[0013] Such as figure 1 , 2 As shown, the suction and drainage assembly of the present invention includes a main drainage pipe 1, a capillary permeable drainage belt 2 and a water flow conversion section 3, the main drainage pipe 1 adopts a PVC pipe with better hardness, and the capillary permeable drainage belt 2 is a water absorption effect. A good new water-absorbing material is generally used for laying it on a plane. In the present invention, the capillary permeable drainage belt 2 is wrapped and bonded on the outside of the main drainage pipe. The water flow conversion section 3 is a tubular structure sleeved on the main drainage pipe 1 , and there is a gap between the water flow conversion section 3 and the main drainage pipe 1 . The left end of the capillary permeable drainage belt 2 is tightly connected to the right end of the water flow conversion section 3 while keeping the gaps connected. The right end of the main drainage pipe 1 is provided with a pipe cap 4 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com