Magnetic core of rectangular flat transformer

A flat-panel transformer, rectangular technology, applied in the direction of transformer/inductor core, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of close distance between winding leads, inconvenient wiring, obvious lead interference, etc. Achieving the effect of avoiding cracking, convenient lead and small loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

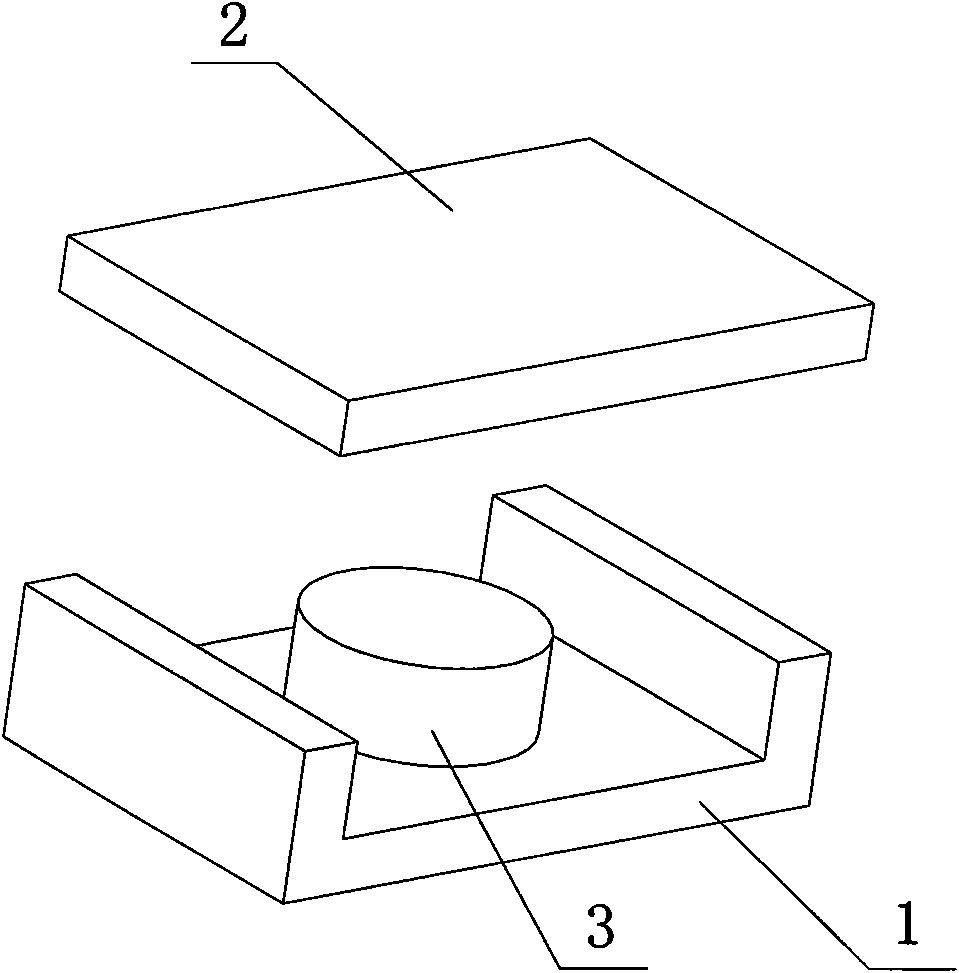

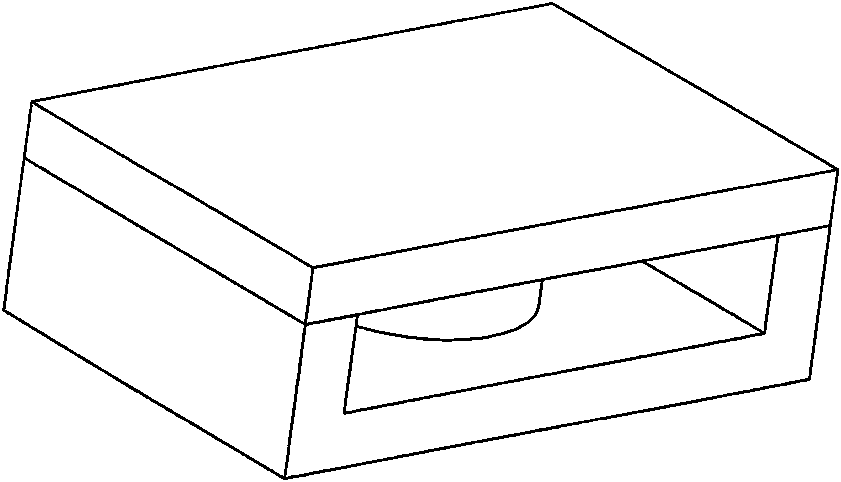

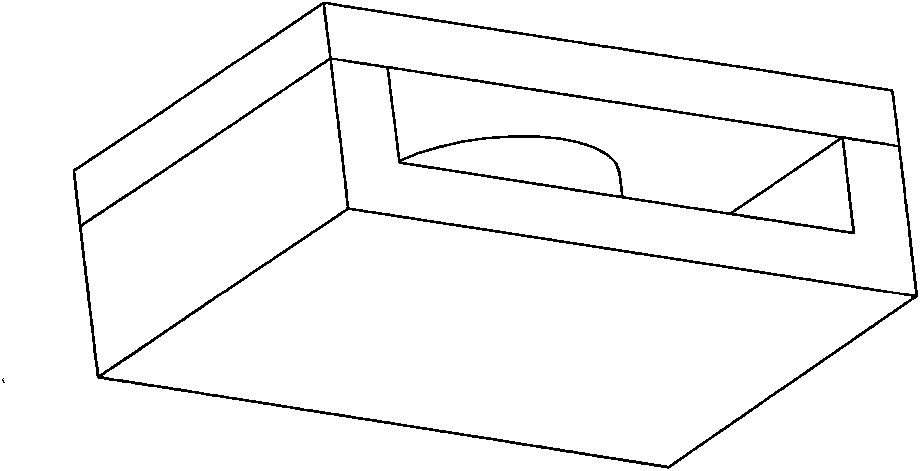

[0012] The rectangular plate transformer magnetic core includes a groove-shaped main body 1 and a cover plate 2. The center of the main body 1 is a cylindrical winding post 3. The shape of the main body 1 is rectangular, and the cover plate 2 cooperates with the main body.

[0013] The main body 1 and the cover plate 2 are connected by glue. Since the main body 1 is rectangular and has a large opening, the lead wires of the windings can be far apart, reducing mutual interference and making wiring more convenient. Such as Figure 1-5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com