Housing body surface plastering machine

A plastering machine and surface layer technology, which is applied in the direction of construction and building structure, can solve the problems of high labor cost, low efficiency and long construction period, and achieve the effect of short construction period, high efficiency and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

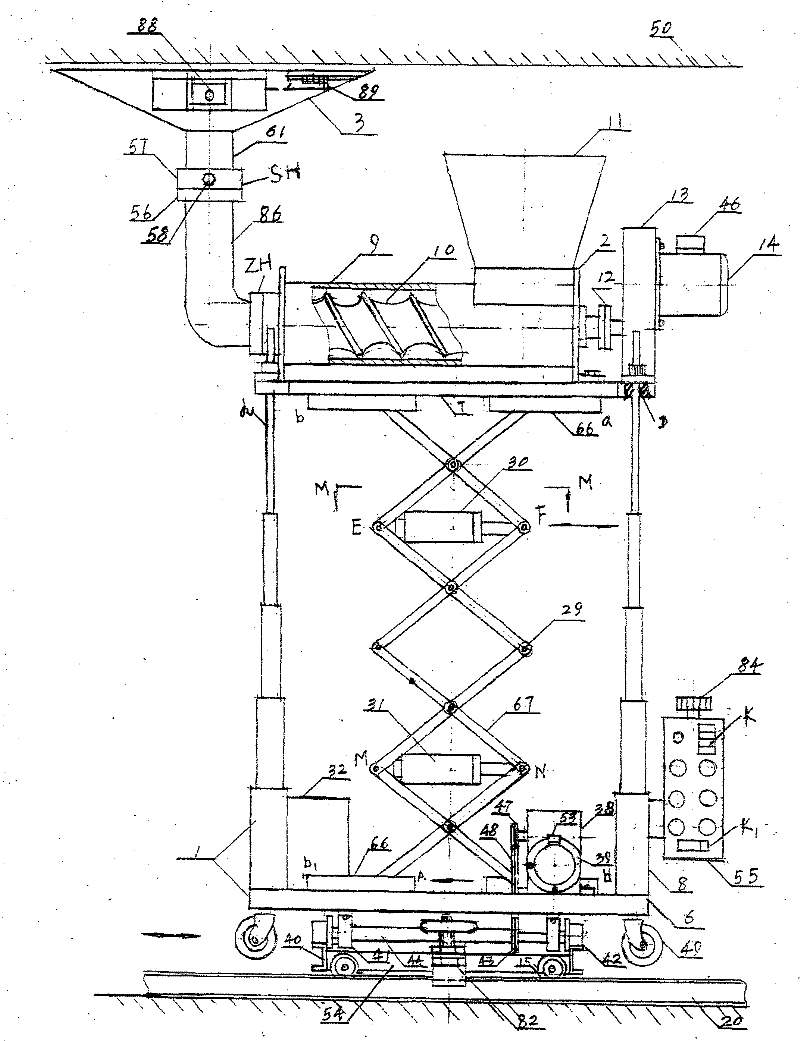

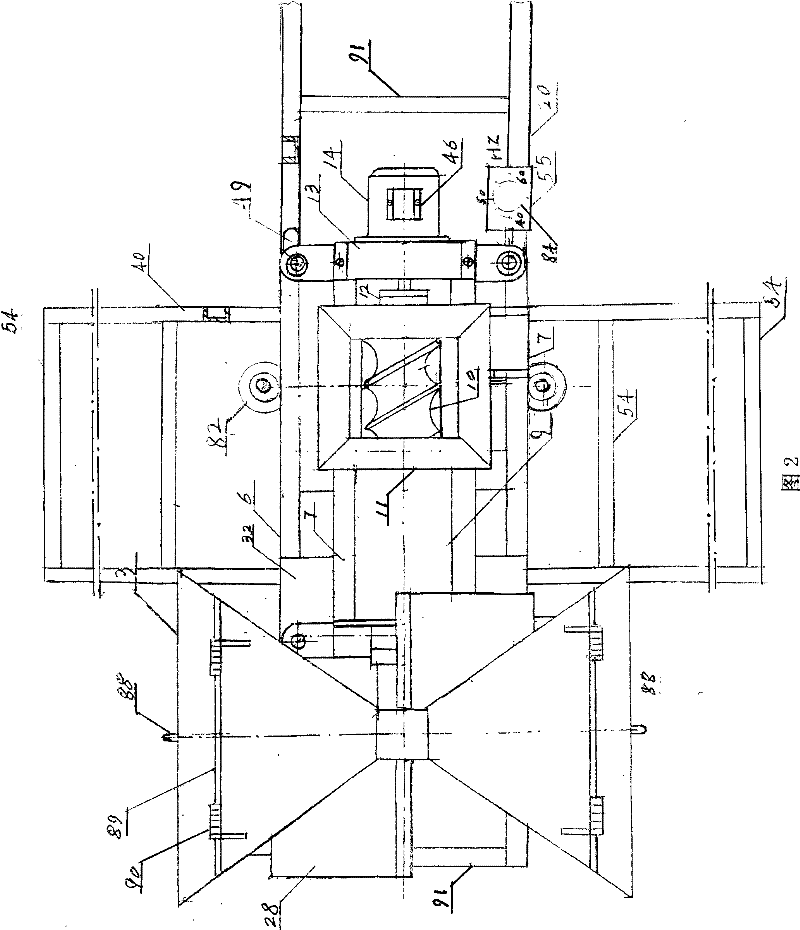

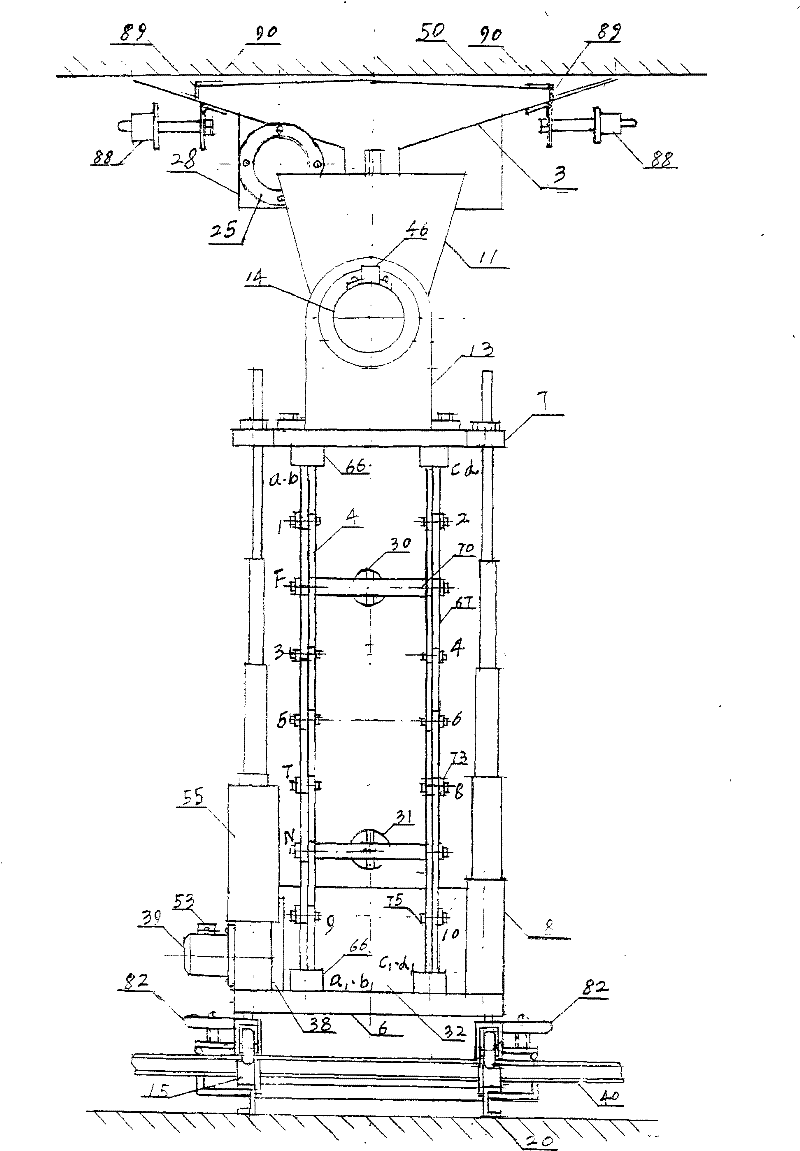

[0023] Below in conjunction with accompanying drawing and example the present invention will be described in further detail, embodiment sees Figure 1-Figure 13 , the plastering machine for the surface layer of the house body, the machine base 7 is equipped with a screw ash discharger 2, a plastering device 3, and the machine base 7 is placed below and the bottom frame 6 is placed on the bottom frame 6 and respectively welded and fixed raceway blocks 66 (a, b, a 1 , b 1 , c, d, c 1 、d 1 ) The gear 76 on the end of the support beam, the bearing rollers 68 at both ends of the gear shaft 78 are respectively meshed with the rack 77 on the raceway block 66 and the raceway 79 is rolled and assembled. Figure 8 , the support beam 67 scissors movable fulcrum (1-10) is equipped with a flat gasket 72 in the middle and is movably assembled by the shaft 75 and locked with a circlip 73. The g hole at the end of the oil cylinder 30, 31 piston rod 71B and the A74m hole at the end of the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com