Straight-through type solar energy vacuum heat collecting tube

A vacuum heat collecting tube and solar energy technology, which is applied in the field of heat collecting tubes, can solve the problems of poor feasibility, can not achieve explosion-proof tubes, explosion tubes, etc., and achieve the effects of good economic and social benefits, simple structure design, and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

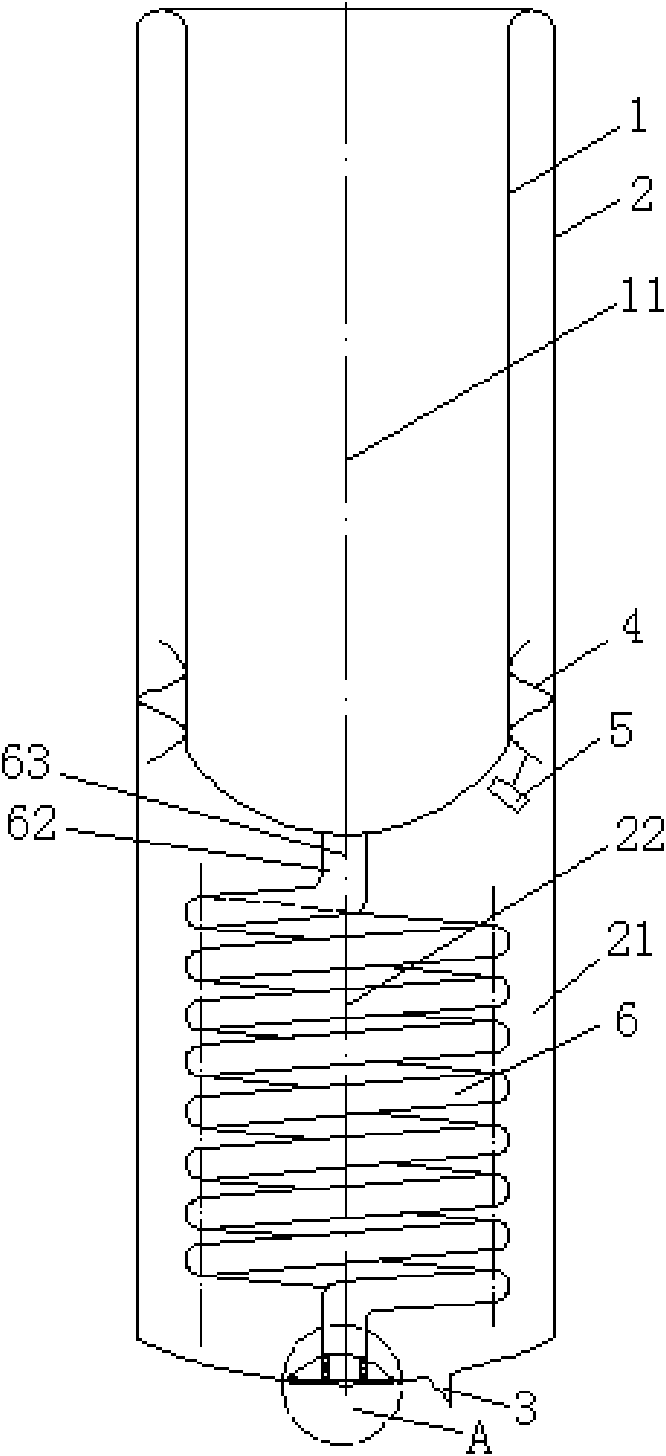

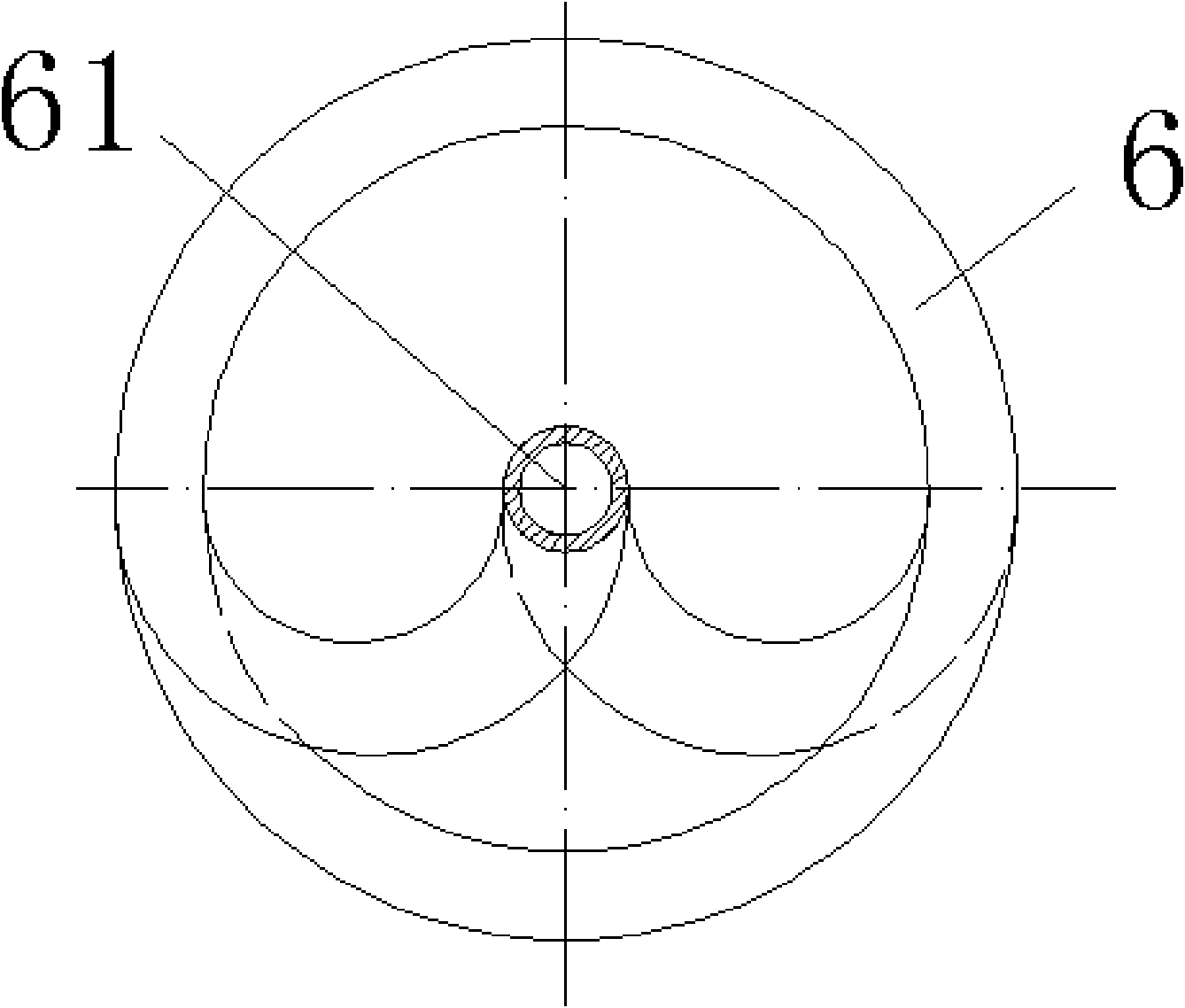

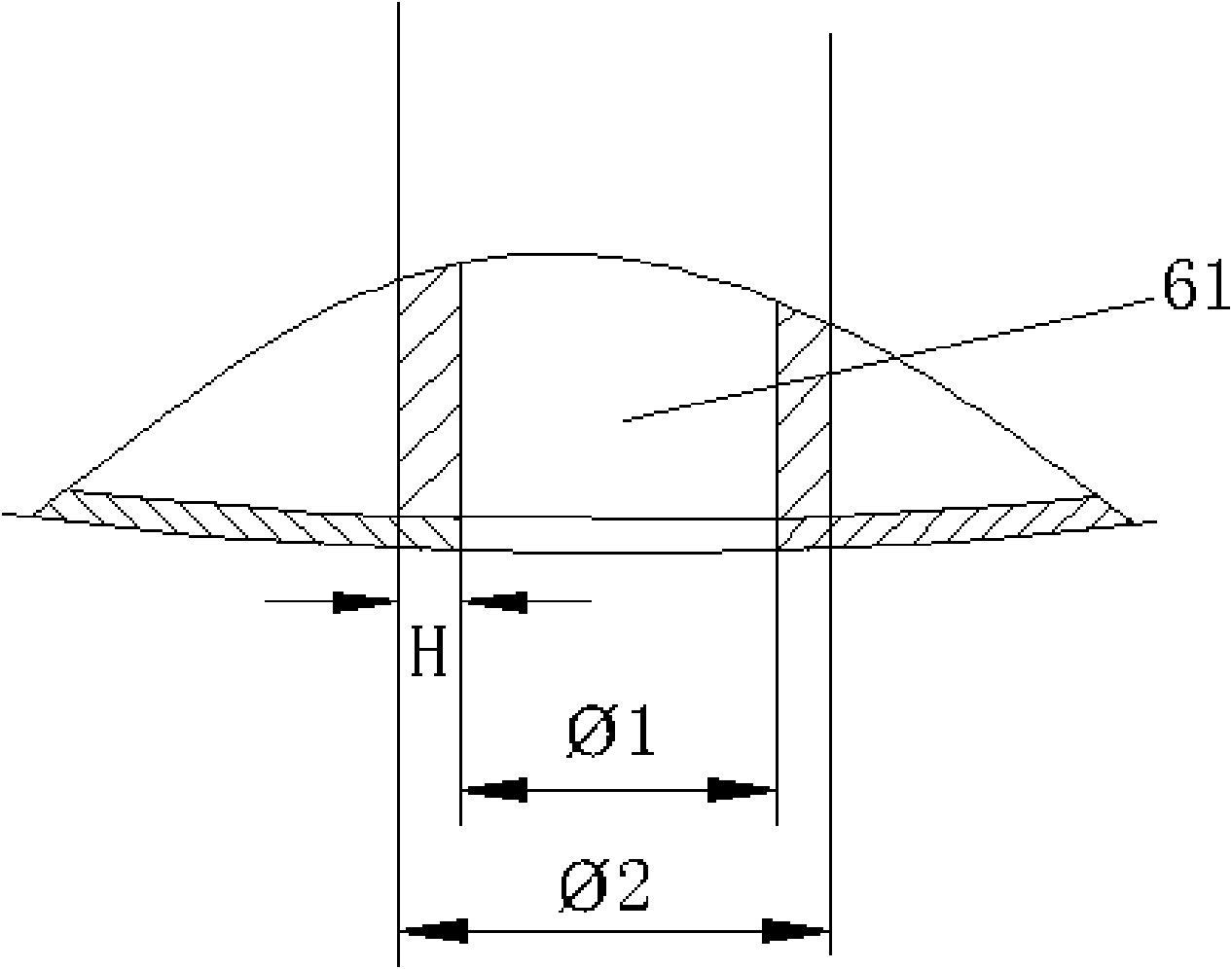

[0029] see Figure 1-Figure 3 , This embodiment is mainly composed of glass inner tube 1, glass outer tube 2, exhaust exhaust tail end 3, metal clip 4, air getter 5 and elastic glass coil 6.

[0030] The glass inner tube 1 and the glass outer tube 2 of the present invention are both hollow tubes, the glass inner tube 1 is located in the glass outer tube 2, and the inner and outer tube centerlines 11, 22 of the glass inner tube 1 and the glass outer tube 2 Coincident; the glass inner and outer tubes 1 and 2 are both evacuated; the exhaust tail end 3 is set on the glass outer tube 2, the air getter 5 is connected with the metal clip 4, and the metal clip 4 is located between the glass inner tube 1 and the glass outer tube. Between the tubes 2 and close to the lower part of the glass inner tube 1. Wherein: the metal clip 4 is used to prevent the eccentricity of the glass inner tube 1; the gas getter 5 is used to eliminate the residual gas in the vacuum tube, improve the vacuum d...

Embodiment 2

[0041] see Figure 4 Figure 5 , The present embodiment is also mainly composed of a glass inner tube 1, a glass outer tube 2, an exhaust exhaust tail end 3, a metal clip 4, an air getter 5 and an elastic glass coil 6.

[0042] Both ends of the flexible glass coil 6 are straight tubes 62, 65, and the direction of the axis is also the same as the axis of the glass outer tube 2, that is, the direction of the center line 22 of the outer tube; but in this embodiment, the straight The axes 621, 651 of the tubes 62, 65 do not coincide with the axis of the outer glass tube 2, that is, the centerline 22 of the outer tube, but are located on the side of the centerline 22 of the outer tube of the glass outer tube 2, and are aligned with the outer tube centerline 22 of the outer glass tube 2. The centerlines 22 are parallel.

[0043] Of course, the axes of the straight tubes 62 and 65 at both ends of the flexible glass coil 6 may not be on the same axis, but must be in the same directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com