Method for eliminating deflection in process of processing main rack of rolling mill

A technology of processing process and main frame, applied in the direction of metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of error, time-consuming and laborious, affecting the accuracy of the main frame, etc., to ensure accuracy, eliminate influence, and eliminate deflection deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

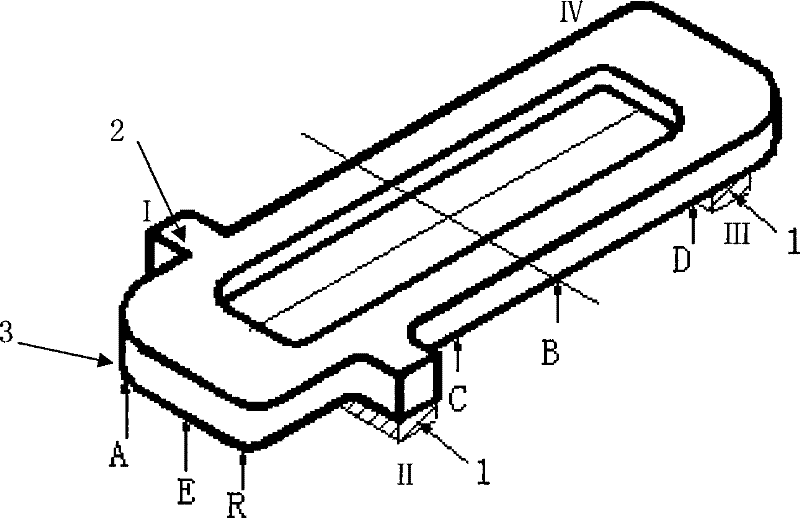

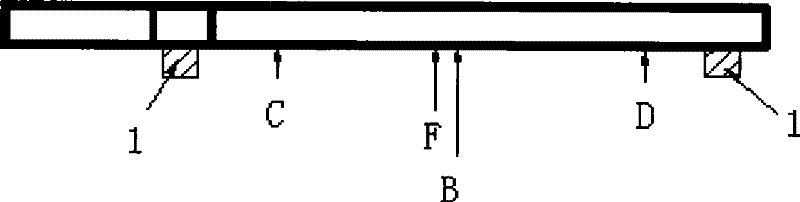

[0020] In order to effectively eliminate the deflection of the main frame due to its own weight and control the influence of the deformation of the main frame on the accuracy of the rolling mill, the present invention adopts the following method to control the deflection and deformation of the main frame due to its own weight.

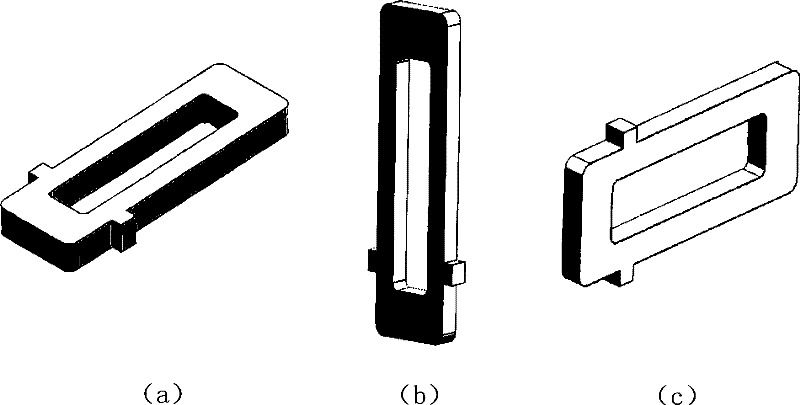

[0021] 1. Deflection control of the main frame in the rough state

[0022] See figure 2 As shown, the main frame has a rectangular shape, with ears 2 extending symmetrically at both ends of one side. After the marking platform is cleaned, draw a cross line according to the center of the length and width of the marking platform, and draw a rectangular line with the center of the cross line as the center. Place the main frame within the rectangular line on the marking platform, and place the main frame in the middle of the rectangular line (the purpose of this is to make the main frame roughly aligned when it is placed). With the inner side of the main fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com