Synchronous centering and positioning device

A technology for centering positioning and fixing shafts, which is applied in positioning devices, workpiece clamping devices, clamping, etc., and can solve problems such as difficulty in fixing the same workpiece at the same position, unreliable processing quality of workpieces, inaccurate repeated positioning, etc. , to achieve the effect of eliminating asynchronous defects, compact structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The following description is only exemplary and does not limit the protection scope of the present invention.

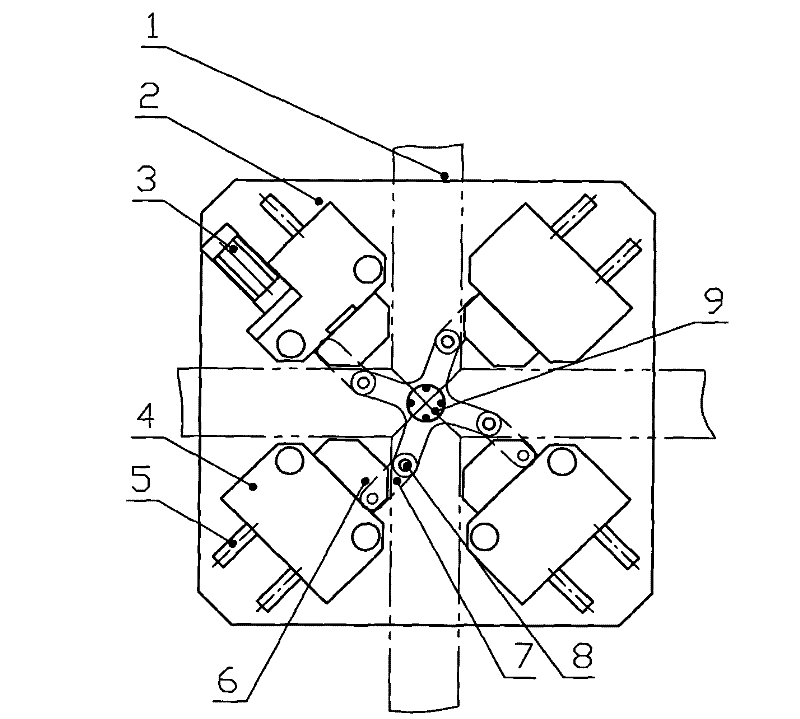

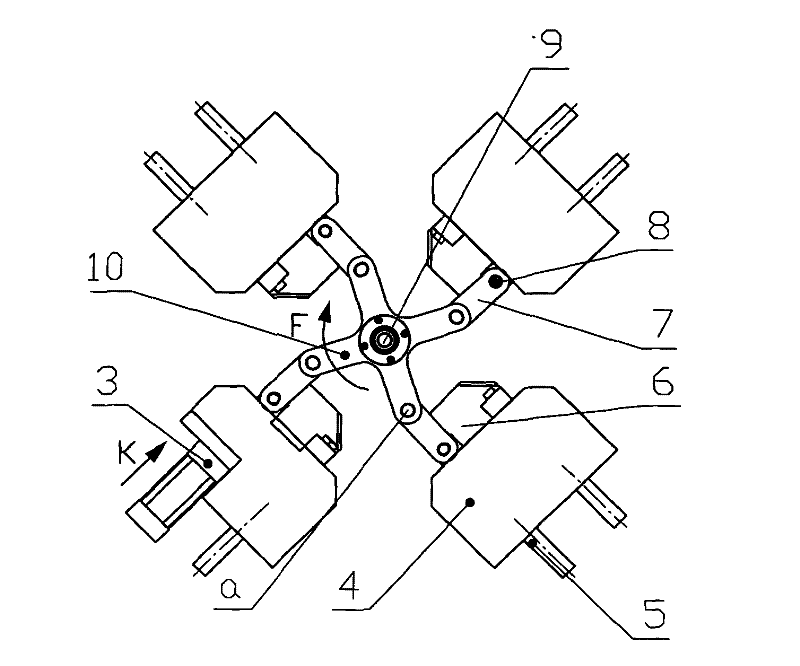

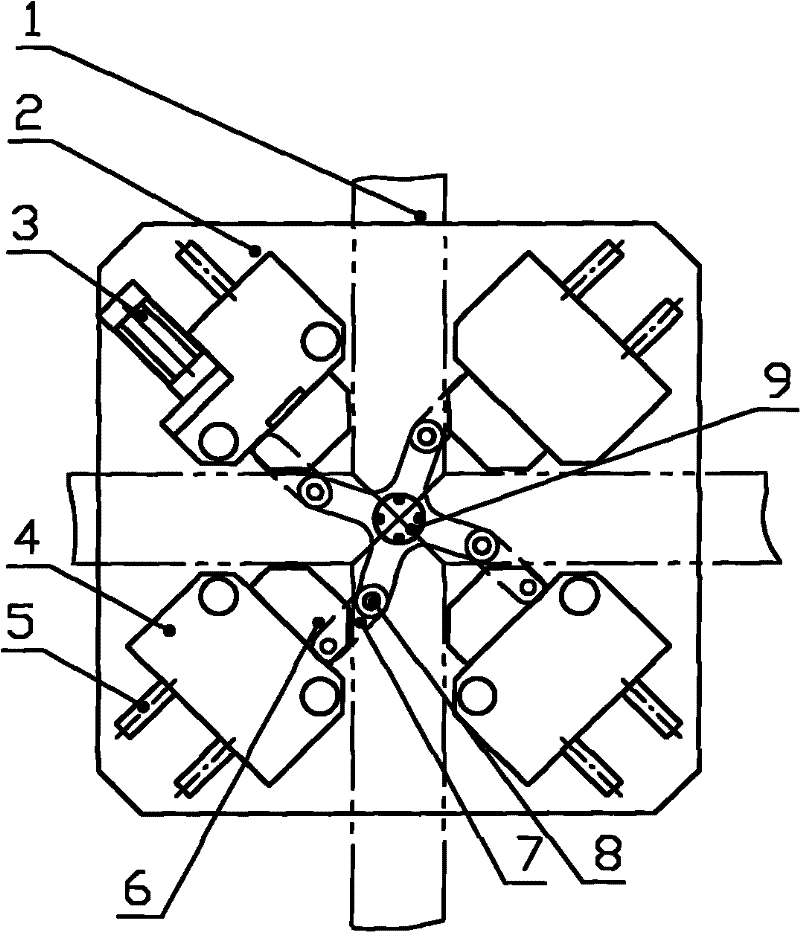

[0018] Such as figure 1 , 2 A specific embodiment of the application of the present invention in the positioning of cross-shaped workpieces is shown, which includes four slider linkages arranged on the same worktable 2, a fixed shaft 9 and a 4 A rotating plate 10 with a mounting hole a, wherein a drive mechanism is connected to the end of the slider 6 of a slider link mechanism, and the slider link mechanism is distributed along the angle bisector of the corner of the workpiece. In the slider link mechanism The slider is slidably installed on two parallel guide shafts 5 arranged at a certain distance on the workbench 2 through the guide shaft seat 4. One end of the connecting rod 7 is hinged on the slider 6 for alignment thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com